13

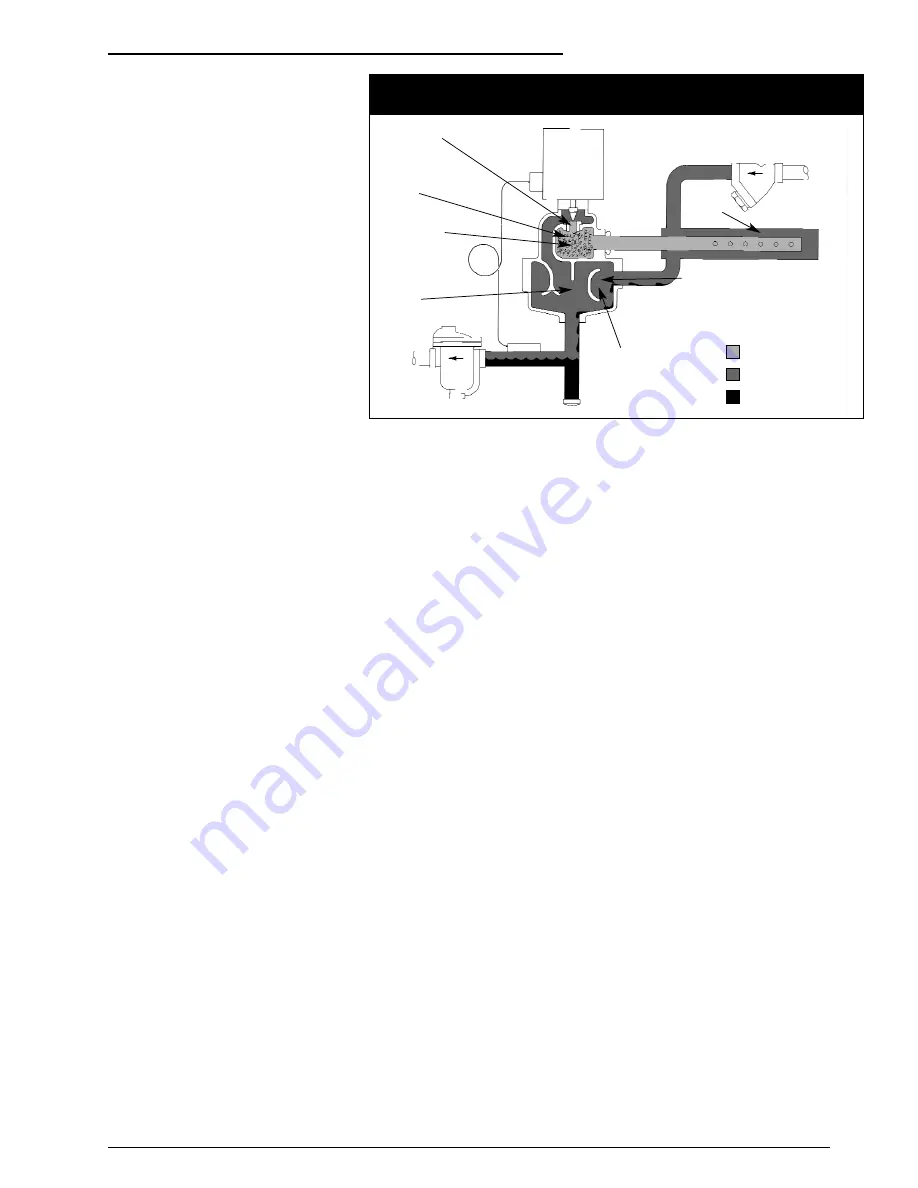

How Duct Type Humidifiers Work

After passing through the Armstrong

inline strainer, steam supply enters the

steam jacket of the manifold and

circulates around the distribution pipe.

Steam now enters the cast iron steam

separating chamber. The use of cast

iron as a separator is probably the

single most important feature in the

Armstrong humidifier design.

The preferred material of strength and

durability, cast iron gives Series 9000

humidifiers flexibility in design without

fabrication. In addition, castings mean

better heat retention because of

thicker walls. Which in turn means a

lower rate of condensation.

Entering the main separating chamber,

steam encounters a cupped baffle

which reverses its flow and turns it

back on itself. The outer walls of the

casting form another cup, and the

same thing happens again. These two

180° turns help condition the steam,

reducing its volume and separating the

condensate from the vapor.

Condensate from supply and radiation

and most of the particulates in the

steam not removed by the strainer

collect in the large drain leg and are

discharged through the inverted

bucket drain trap.

Steam from the separating chamber

flows around and through the valve

which is actuated by a demand signal

from the humidistat.

Next the steam flows into the drying

chamber which is jacketed by the

separating chamber. The drying

chamber is filled with a stainless steel

silencing material which almost

completely absorbs the noise of

escaping steam

How air-operated units work.

Air-operated units operate in the same

manner as electric units except that

they utilize a pneumatic humidistat as

humidity controller in the space and an

air operator to open and close the

steam valve.

Explosion hazard

humidification.

Sizing air-operated humidifiers for

areas where an explosion hazard

exists is done exactly as for other

requirements except that they should

be sized for the most severe

conditions of makeup air, RH required

and minimum steam pressure.

Putting the Humidifier

Into Operation

When Temperature Switch Is

Employed simply set humidity

controller at desired level, and turn on

the steam.

When Temperature Switch Is Not

Employed deactivate operator control

so that humidifier control valve will

remain closed. Then:

A. Open steam supply valve to bring

humidifier up to temperature.

B. When drain line from humidifier is

at steam temperature, activate the

operator control.

C. Set desired relative humidity.

After the Humidifier

Is In Operation

Clean Strainer. The screen in the

strainer installed in the steam supply

line should be cleaned a few days

after the humidifier is placed in

operation, and thereafter at least once

each season—more often if you find

much dirt in the screen.

Check Trap. The steam trap used to

drain the humidifier should be

inspected at the same time the

strainer is cleaned.

Trouble Shooting

Humidifier Will Not

Discharge Steam

A. Control System at Fault.

1. Faulty control valve operator.

2. Faulty humidity controller.

3. Faulty connections between

humidity controller and control

valve operator.

B. Steam System Malfunction.

1. Silencing chamber plugged with

dirt. Remove and replace

silencing material and retainer.

2. Strainer screen plugged.

3. Dirt in steam line.

4. Steam valve closed in line to

humidifier.

5. Pressure reducing valve out of

order.

Humidifier Discharges Water

A. Faulty Steam Supply.

1. Long, untrapped suppy line.

2. Humidifier supply from bottom or

side of steam header.

3. Untrapped valve in vertical,

down feed supply line.

4. Boiler carryover.

B. Faulty Drainage.

1. Steam trap filled with dirt.

2. Return line pressure above

humidifier pressure.

3. Too much vertical lift.

4. Wrong type of drain trap used.

Always use the Armstrong

Inverted Bucket Steam Trap.

C. Faulty Operation.

1. Faulty temperature switch.

2. Humidity controller set up before

humidifier has reached steam

temperature.

Humidifler Discharges

Continuously even though

humidity has reached desired level.

A. Humidity controller out of

calibration.

B. Trouble in Humidifier

1. Valve stem “frozen” to stem seal

due to unusual chemical or

corrosive conditions in steam

system.

2. Operator spring broken.

3. Dirt or scale between valve and

seat.

Operating and Servicing

Figure 13-1. How Armstrong Conditioned Steam Humidifiers operate for air handling

humidification

Steam jacketed valve

positioned by

controller

Silencing

chamber

Steam jacketed

drying chamber

Separating

chamber

Abrupt change in

flow

Condensate formed in

supply line knocked

down by baffle

Steam at supply pressure

Steam at atmospheric

pressure

Condensate

Steam

jacketed

manifold

Steam supply