Separator

Size

Minimum

Pipe Size

Suggested

Header Size

90

1/2"

3/4"

91

1/2"

2"

92

3/4"

2-1/2"

93

1"

3"

94

2"

5"

15

SteamStik Almuminum Manifolds

Preliminary Procedure

STEP 1: Check Shipment Against

Packing List.

All components are

listed on the packing slip. Report any

shortages

immediately

. If the

humidifier or accessories have been

damaged in transit, notify us and file

claim with the transportation company.

If your order covers more than one

unit, separate each complete unit.

Humidifier tagging and manifold

tagging will be the same as shown on

the packing list. Model, Serial Number,

Steam Pressure, Orifice and Orifice

Restriction (if any) are on the metal

plate on the humidifier body. Operator

for electric motor operated unit is

shipped separately but marked with

the serial number of the humidifier

with which it must be used. Be sure

serial numbers agree.

STEP 2: Spot Humidifier Locations.

Locate each humidifier according to

the engineer’s layout or as indicated

by your Armstrong Representative. If

you must locate the humidifiers

yourself, be sure to read and observe

the “Do’s and Don’ts” on the following

page.

Manifold Installation

STEP 3: Cut Hole in Duct or Plenum

for Manifold.

Cut a 2” hole for each

manifold location.

STEP 4: Insert Manifold in Duct.

Outlet holes must point upstream into

air flow with

all

SteamStik manifolds.

Where manifold is positioned

horizontally, use a spirit level.

Manifolds longer than one foot should

be supported. When supporting the

manifold on the far end allow for

manifold expansion and contraction of

1/2” - 1".

Continue installation with step 5

beginning on page 8.

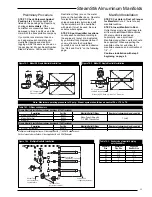

90° Compression

Elbow and Tube

*

90° Compression Elbow

and Male End Adaptor

*When using 90° Elbow, maintain 2.65” Dimension)

Figure 15-2. Model 91 Single Manifold Installation

Figure 15-1. Model 90 Single Manifold Installation

Note: Maximum operating pressure is 15 psig. Steam system should have a neutral Ph of 7.2 to 7.6.

Description

Part No.

Manifold Outlet Fittings

Number of reducer bushing(s) supplied

Model 90 Horizontal

B4583

Model 90 Vertical

B4584

Model 91

B3931

Description

Part No.

Manifold Outlet Fittings

Number of reducer bushing(s) supplied

All 90/91 Installations

A4967B

Not Applicable

2 (1 inlet, 1 outlet)

Single Manifold Installation (reducer bushings A17891 included)

Elbow/Tube Fitting with

1/2" MNPT Connection

1 (inlet)

Multiple Manifold Installation

Table 15-1. Fittings and Adaptors

Multiple manifold applications will be supplied with (1) A4967B adapter each.

Vertical mounted manifolds will be supplied with an A4967B adapter.

Union/Nipple

(supplied by customer)

Support Rod

(supplied by customer)

Header Trap

must be drained

to atmosphere

F&T Steam Traps

(purchased seprately)

Figure 15-3. Multiple Manifold Installation

Table 15-2. Header size of manifold piping

out of humidifier

Single Manifold Installation (reducer bushings A17891 included)

Single Manifold Installation (reducer bushings A17891 included)