2

These instructions cover the

installation of the models listed below:

Air Operated (AM):

90 - 94 Sizes (Cast Iron)

1200 - 1400 Sizes (Stainless Steel)

Electric Motor Operated (HEM):

90 - 94 Sizes (Cast Iron)

1200 - 1400 Sizes (Stainless Steel)

Electric “On-Off” (DSA):

90 - 93 Sizes (Cast Iron)

Preliminary Procedure

STEP 1: Check Shipment Against

Packing List.

All components are

listed on the packing slip. Report any

shortages

immediately

. If the

humidifier or accessories have been

damaged in transit, notify us and file

claim with the transportation company.

If your order covers more than one

unit, separate each complete unit.

Humidifier tagging and manifold

tagging will be the same as shown on

the packing list. Model, Serial Number,

Steam Pressure, Orifice and Orifice

Restriction (if any) are on the metal

plate on the humidifier body. Operator

for electric motor operated unit is

shipped separately but marked with

the serial number of the humidifier

with which it must be used. Be sure

serial numbers agree.

STEP 2: Spot Humidifier Locations.

Locate each humidifier according to

the engineer’s layout or as indicated

by your Armstrong Representative. If

you must locate the humidifiers

yourself, be sure to read and observe

the “Do’s and Don’ts” on the following

page.

Manifold Installation

STEP 3: Cut Hole in Duct or Plenum

for Manifold.

Use manifold

dimensions “X” and “Y” from Table 2-

2, below, and add approximately

1

¼

4

"

for manifold clearance. If multiple

manifolds are used, read page 9 first.

STEP 4: Insert Manifold in Duct.

Outlet holes must point upstream into

air flow,

except on insulated

manifolds point discharge holes

downstream.

Where manifold is

positioned horizontally, use a spirit

level. Manifolds longer than one foot

should be supported. Put the two

piece manifold escutcheon plate in

position. When supporting the

manifold on the far end allow for

manifold expansion and contraction of

1/2" - 1”.

Instructions continued on page 8

Preliminary Procedure and Manifold Installation

Table 2-2. Cross-Section Dimensions

Model “N”

“R”

“S”

“T”

“X”

“Y”

Steam

Condensate Alternate

Supply

Drain

Inlet

90 Size

5

3

/

8

"

2"

1"

1"

1

1

/

4

"

1

7

/

8

"

1

/

2

" NPT

1"

1

/

2

"

91 Size

5

11

/

16

"

2"

1"

1"

1

1

/

4

"

1

7

/

8

"

1

/

2

" NPT

1"

3

/

4

"

92 Size

8

9

/

16

"

2"

1"

1"

1

3

/

4

"

2

5

/

8

"

3

/

4

" NPT

1"

3

/

4

"

1200 Size

8

9

/

16

"

2"

1"

1"

1

3

/

4

"

2

5

/

8

"

3

/

4

" NPT

1"

3

/

4

"

93 Size

9

1

/

16

"

2"

1

5

/

8

"

1

5

/

8

"

2

1

/

8

"

3

1

/

8

"

1

1

/

4

" NPT

1

1

/

4

"

1

1

/

4

"

1300 Size

9

7

/

8

"

2"

1

5

/

8

"

1

5

/

8

"

2

1

/

8

"

3

1

/

8

"

1

1

/

4

" NPT

1

1

/

4

"

1

1

/

4

"

94 Size

13

1

/

2

"

2"

1

5

/

8

"

1

5

/

8

"

3

1

/

4

"

4

1

/

4

"

2" NPT

2"

2"

1400 Size

14

5

/

16

"

2"

1

5

/

8

"

1

5

/

8

"

3

1

/

4

"

4

1

/

4

"

2" NPT

2"

2"

Table 2-1. Dimensions in Inches

Model No.

B

C

D

E

F

AM-90

8

7

/

8

–

2

3

/

8

2

7

/

16

2

13

/

16

HEM-90

15

1

/

2

–

2

3

/

8

2

7

/

16

2

13

/

16

DSA-90

7

–

2

3

/

8

2

7

/

16

2

13

/

16

AM-91

16

3

3

/

8

3

1

/

16

6

1

/

16

3

13

/

16

HEM-91

19

1

/

2

3

3

/

8

3

1

/

16

6

1

/

16

3

13

/

16

DSA-91

10

7

/

8

3

3

/

8

3

1

/

16

6

1

/

16

3

13

/

16

AM-92

16

3

3

/

8

3

13

/

16

6

1

/

16

3

13

/

16

HEM-92

19

1

/

2

3

3

/

8

3

13

/

16

6

1

/

16

3

13

/

16

DSA-92

10

7

/

8

3

3

/

8

3

13

/

16

6

1

/

16

3

13

/

16

AM-1200

10

3

/

8

3

13

/

16

3

13

/

16

6

11

/

16

9

11

/

16

HEM-1200 10

3

/

8

3

13

/

16

3

13

/

16

6

11

/

16

13

1

/

4

AM-93

19

1

/

8

4

5

/

8

4

3

/

4

9

4

3

/

4

HEM-93

22

3

/

4

4

5

/

8

4

3

/

4

9

4

3

/

4

DSA-93

14

1

/

2

4

5

/

8

4

3

/

4

9

4

3

/

4

AM-1300

16

3

/

4

6

5

9

/

16

10

5

/

16

10

15

/

16

HEM-1300 16

3

/

4

6

5

9

/

16

10

5

/

16

14

3

/

16

AM-94

23

1

/

2

6

7

/

8

8

12

5

/

8

8

HEM-94

28

1

/

2

6

7

/

8

8

12

5

/

8

8

AM-1400

24

5

/

8

8

15

/

16

8

5

/

16

14

11

/

16

12

HEM-1400 24

5

/

8

8

15

/

16

8

5

/

16

14

11

/

16

16

1

/

2

Table 2-3. Manifold Lengths and Duct Widths With Which They May Be Used

Manifold Model No.

M-1 M-1.5 M-2 M-3 M-4 M-5 M-6 M-7 M-8 M-9 M-10 M-11 M-12

(L) Length

12"

18"

24"

36"

48" 60"

72" 84"

96" 108" 120" 132"

144"

W - Duct

(Min)

8"

15"

21"

31"

43" 53"

65" 77"

89" 101" 113" 125"

137"

Width

(Max)

14"

20"

30"

42"

52" 64"

76" 88" 100" 112" 124" 136"

148"

Table 2-4. Model 90 Manifold Lengths and Duct Width With Which They May Be Used

Vertical Air Flow No.

MV-1 MV-1.5 MV-2 MV-3 MV-4 MV-5 MV-6 MV-7 MV-8 MV-9 MV-10 MV-11 MV-12

Horizontal Air Flow No. MH-1 MH-1.5 MH-2 MH-3 MH-4 MH-5 MH-6 MH-7 MH-8 MH-9 MH-10 MH-11 MH-12

(L) Length

12"

18"

24"

36"

48" 60"

72" 84"

96" 108" 120" 132"

144"

W - Duct

(Min)

8"

15"

21"

31"

43" 53"

65" 77"

89" 101" 113" 125"

137"

Width

(Max)

14"

20"

30"

42"

52" 64"

76" 88" 100" 112" 124" 136"

148"

NOTE: Insulated manifolds available. Consult factory.

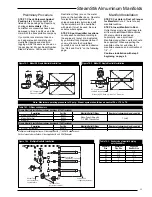

Figure 2-1. Humidifier Dimensions

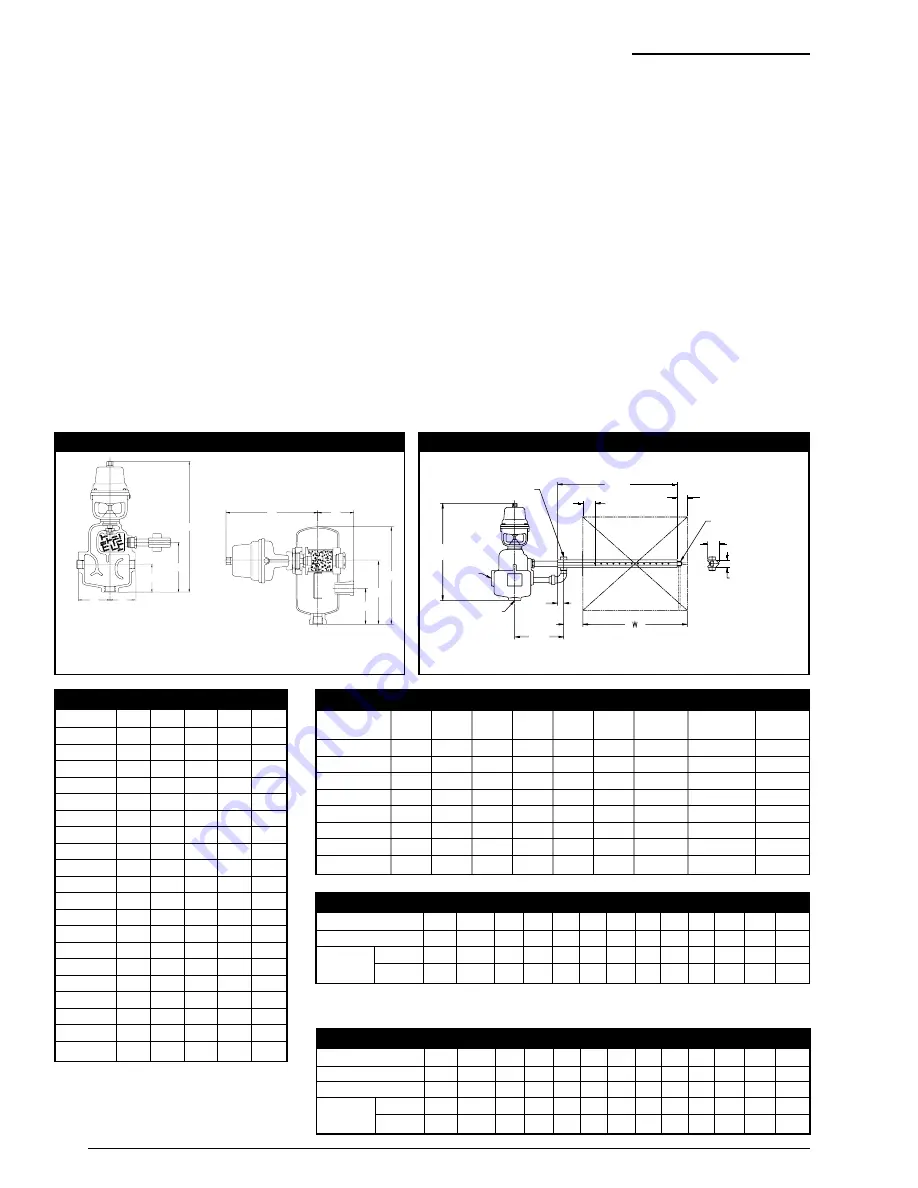

Figure 2-2. Steam Distribution Manifold Data

Sectional view of

Model 1200

Sectional view of AM9000. Model

EM9000 is similar except for

operator. See Table for dimensions.

See Page 14 for Mounting Hole Information.

E

C

D

F

B

D

B

E

C

F

Alternate

Inlet

Condensate

Drain

B

S

N

(min)

T

(min)

L

R

(min)

W

X

1" Min.

Support for Manifold

(Not furnished on M-1 Size)

Y

Steam Supply