3

All recommendations for the application of Armstrong

Humidifiers are based on tests and field experience.

However, they are based on duct air velocities and

temperatures that are most commonly encountered, and the

recommendations may have to be modified when velocities

are very high and/or temperatures unusually low. We also

reserve the right to modify recommendations without notice

if subsequent tests or experience indicate that a change

should be made. For these reasons, we urge that you check

all applications with your Armstrong Representative before

installation.

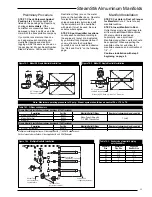

Do’s and Don’ts of Humidifier Location and Installation

The 9000 & 1000 Series must always be perpendicular to the floor!

Fig. 3-1. Always select the steam

distribution manifold length that will span

the maximum width of duct.

Fig. 3-5. Whenever possible, install

distribution manifold downstream from

coils. If more than 3' of distance between

manifold and coil on upstream side is

available, it is permissible to install at this

location.

Fig. 3-9. When it is necessary to place

humidifier discharge into a “packaged”

multi-zone air handling system, install

distribution manifold into center of

active

air flow

and as close to fan discharge as

possible.

Fig. 3-10. Always install distribution

manifold as far upstream from a discharge

air grille as possible—never less than 3'.

This also applies to elbows, splits,

transitions, ducts, etc.

Fig. 3-11. Dispersion manifold should

never be placed within 3' of an air fan

intake. The desirable location would be at

the fan discharge.

Fig. 3-12. Do not install manifold closer

than 5' upstream of temperature controller.

Fig. 3-6. Do not restrict air flow in ducts 8"

or less in depth. Utilize an expanded

section.

Fig. 3-7. Do not install the distribution

manifold less than 10' upstream from a

high efficiency filter. Locate high limit duct

humidity controller immediately upstream

from the filter.

Fig. 3-8. When it is necessary to place

humidifiers in coil section

ahead

of fan,

locate manifold in most active air flow and

as far upstream from fan inlet as possible.

Fig. 3-2. When possible, install the steam

distribution manifold into the center of duct.

Fig. 3-3. Manifold should never be

installed vertically downward from control

valve. This presents a condensate

drainage problem in the jacket of the

manifold. Vertically upward installation is

permissible.

Fig. 3-4. Always size and install dispersion

manifold to span the widest dimension of

the duct section.