Bulletin 549-A

This bulletin should be used by experienced personnel as a guide to the installation and maintenance of AM-91A,

-92A, 93A; AMAF-91A, -92A, -93A; AMEF-91A, -92A, -93A; FSA-91A, -92A, -93A; VSA-91A, -92A, -93A direct area humidifi ers. Se-

lection or installation of equipment should always be accompanied by competent technical assistance. We encourage you to contact

Armstrong or its local representative if further information is required.

Installation and Operation

AM-91A, -92A, 93A; AMAF-91A, -92A, -93A; AMEF-91A, -92A, -93A;

FSA-91A, -92A, -93A; VSA-91A, -92A, -93A

Humidifi ers for Direct Area Humidifi cation

Step 1. Check Shipment Against Packing List

All components are listed on the packing

slip. Report any shortages immediately. If

the humidi

fi

er or accessories have been

damaged in transit, notify us and

fi

le claim

with the transportation company.

Step 2. Mount the Humidifi er

Support it from the ceiling, Fig. 1-3, or bracket

it to a column as shown in Fig. 1-4. There are

holes on both sides of the humidi

fi

er for mounting

purposes.

Exception:

Where supply and return connections

for the 91 & 92 size are short, a pipe hanger to

the steam supply line should be suf

fi

cient.

Figure 1-3.

Figure 1-4.

Humidifi er suspended from ceiling.

Humidifi er bracketed to column.

*Standard spring — furnished when no spring range is specifi ed.

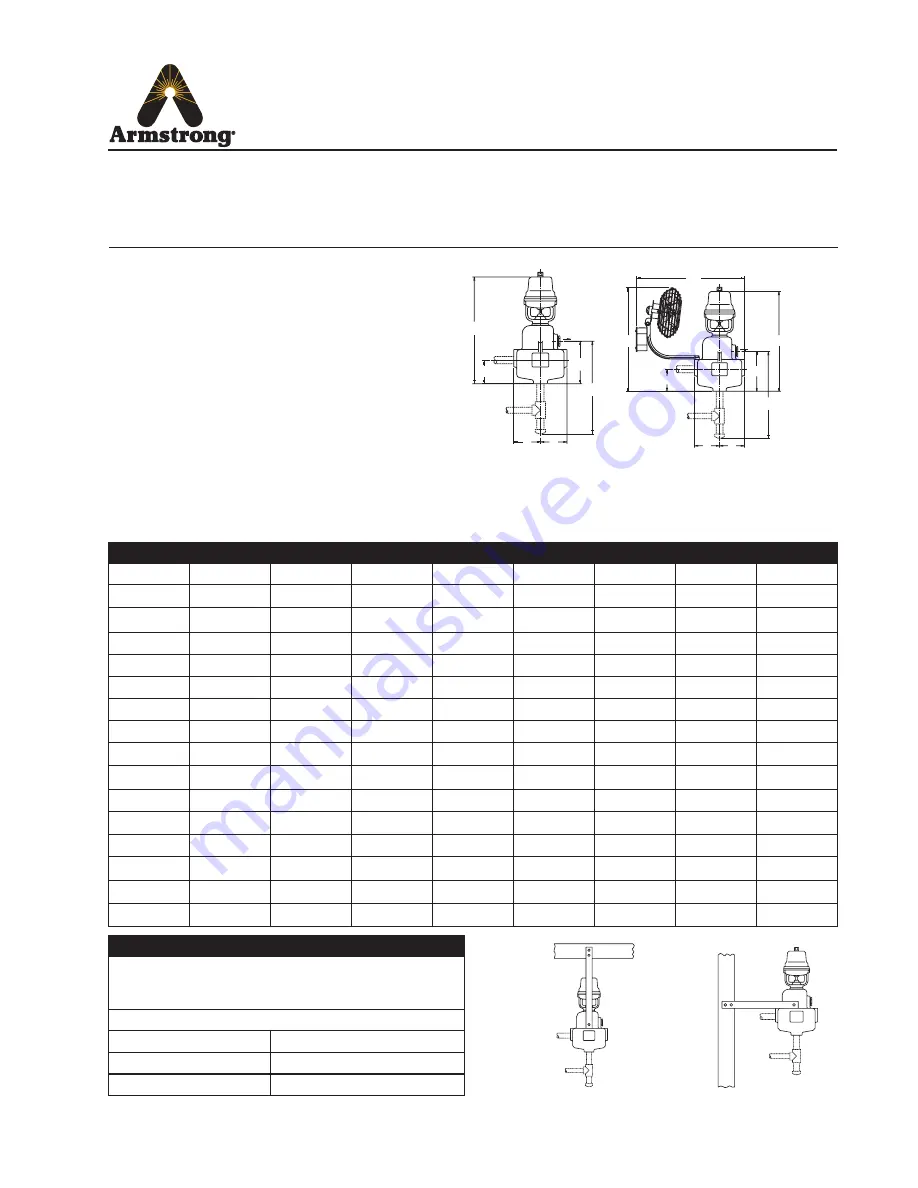

AM, VSA Models

AMEF, AMAF,

FSA Models

Figure 1-1.

Figure 1-2.

Dimensions, Armstrong Area Humidifi ers. Fig. 1-1 VSA, AM models do not

have fans. Fig. 1-2 FSA, AMEF models have electrically operated fans. AMAF

models utilize air powered fans.

Installation Procedure

B

C

D

F

J

E

H

G

C

D

F

B

J

E

Table 1-1

Model No.

B

C

D

E

F

G

H

J

AM-91A

15-15/16”

3-3/8”

3-13/16”

6-1/16”

3-1/16”

—

—

13-1/4”

AMAF-91A

15-15/16”

3-3/8”

3-13/16”

6-1/16”

3-1/16”

15-5/8”

14-9/16”

13-1/4”

AMEF-91A

15-15/16”

3-3/8”

3-13/16”

6-1/16”

3-1/16”

18-9/16”

15-3/4”

13-1/4”

FSA-91A

10-7/8”

3-3/8”

3-13/16”

6-1/16”

3-1/16”

17-3/8”

15-3/4”

13-1/4”

VSA-91A

10-7/8”

3-3/8”

3-13/16”

6-1/16”

3-1/16”

—

—

13-1/4”

AM-92A

15-15/16”

3-3/8”

3-13/16”

6-1/16”

3-13/16”

—

—

13-1/4”

AMAF-92A

15-15/16”

3-3/8”

3-13/16”

6-1/16”

3-13/16”

15-5/8”

14-9/16”

13-1/4”

AMEF-92A

15-15/16”

3-3/8”

3-13/16”

6-1/16”

3-13/16”

18-9/16”

15-3/4”

13-1/4”

FSA-92A

10-7/8”

3-3/8”

3-13/16”

6-1/16”

3-13/16”

17-3/8”

15-3/4”

13-1/4”

VSA-92A

10-7/8”

3-3/8”

3-13/16”

6-1/16”

3-13/16”

—

—

13-1/4”

AM-93A

25-1/2”

4-5/8”

4-3/4”

9”

4-3/4”

—

—

24”

AMAF-93A

25-1/2”

4-5/8”

4-3/4”

9”

4-3/4”

—

17-3/4”

24”

AMEF-93A

25-1/2”

4-5/8”

4-3/4”

9”

4-3/4”

21”

18-1/4”

24”

FSA-93A

20-3/8”

4-5/8”

4-3/4”

9”

4-3/4”

21”

18-1/4”

24”

VSA-93A

20-3/8”

4-5/8”

4-3/4”

9”

4-3/4”

—

—

24”

Table 1-2

Note: AM models 91, 92 and 93 shown on this bulletin are furnished with

Armstrong C-1801 pneumatic operators. Operator Spring Ranges for

pneumatically controlled humidifi ers.

Armstrong C-1801

Operating Range

Adjustable Start Points

5 lbs.

3 psig min. - 6 psig max.

*10 lbs.

3 psig min. - 6 psig max.