4

B. If automatic control is not used, the use of a hand

switch to control the fan motor has de

fi

nite ad-

vantages. The fan operates continuously during

the heating season. The motors are oil less in all

positions. Current consumption is low – 6 watts

for all AMEF models.

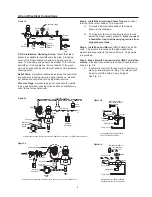

For FSA, VSA Models (See Figs. 3-4 & 3-5)

A. Beware of Voltage Drop. If the wire supplying

current to the humidi

fi

er is too small or too long,

there may be a voltage drop that will reduce the

life of your equipment. When the voltage is too

low, the solenoid valve will not open but current

will continue to

fl

ow and will burn up the coil.

B. 24 Volt Wiring. (VSA Only)

Where codes permit

24 volt wiring without conduit, the use of a 120-24

volt transformer relay, as shown in Fig. 3-5 will

lower the installation cost.

Step 7: Install Pneumatic Piping. (AM)

A. Air

Supply.

Air supply for Armstrong Humidi

fi

ers

should be 15 to 20 psi. This air must be clean and

dry instrument air. Make air connections to fan of

AMAF models.

B. Compressed

Air

Piping.

Plastic tubing or equiva-

lent is used for all air connections.

Step 8: Install Humidity Controller.

Location.

The humidistat should be installed anywhere

from 20 ft. to 30 ft. from the humidi

fi

er – at one side of

the air stream from the humidi

fi

er. The hygrostat should

be able to “see” the unit controlled. It must not be hidden

behind piles of goods or in channels of columns where air

movements cannot reach it. It may be necessary to experi-

ment with the location in order to get the best control.

Setting and Adjusting

should be done in accordance with

the manufacturer’s instructions furnished with the humidi-

stat.

Recommended Option.

A pneumatic or an electric temperature switch is recom-

mended in any system where the steam supply to the

manifold jacket and humidi

fi

er body may be interrupted or

turned off.

Air and Electrical Connections

Sizing and Selection

A survey of your requirements should be taken to deter-

mine the amount of steam needed for humidi

fi

cation, the

number, size and type of units required, and the location of

both humidi

fi

er and humidity controllers.

Sizing and location with natural ventilation.

These are the average industrial humidi

fi

cation applications

with:

Room temperatures – 65° to 80°.

Relative humidities – 35% to 80%.

Natural ventilation – i.e., in

fi

ltration around windows and

doors.

Selection Data Required.

■

Minimum Outdoor Temperature: for most jobs,

fi

gure

10°F above the lowest recorded temperature for your

locality. The lowest temperatures are seldom

encountered for more than a few hours.

■

Indoor Temperature

■

RH Desired

■

Pressure of Steam Available for Humidi

fi

cation

■

Number of Cubic Feet in Room

■

Air Changes Per Hour: air changes taking place under

average conditions exclusive of air provided for

ventilation or regain of hygroscopic materials.

Rooms, 1 side exposed ................... 1

Rooms, 2 sides exposed ................. 1 ½

Room, 3 or 4 sides exposed ............ 2

Rooms with no windows or

outside doors ............................ ½ - ¾

Typical Problem:

Design outdoor temperature ............ 0°F

Indoor temperature .......................... 70°F

RH required ..................................... 40%

Air changes per hour ....................... 2

Steam pressure available ................ 5 psi

Room size 400’ x 160’ with 10’ ceiling.

Natural ventilation

Heated by:

Unit heaters – fan on-off control.

Step 1:

Steam required for humidi

fi

cation. Our room con-

tains (400’ x 160’ x 10’) or 640,000 cu. Ft.

From the 70°F Table 5-1, read across from 0°F outside

temperature to the 40% RH column where you

fi

nd the

fi

gure .409 lbs. of steam per hour per 1000 cu. ft. of space

for each air change. Then, 640 x .409 x 2 equals 524 lbs. of

steam per hour installed humidi

fi

cation capacity required.

Step 2:

Electric or air controlled units. The large

fl

oor area

calls for multiple humidi

fi

ers. No explosion hazard has

been speci

fi

ed so use of air controlled units is not required.

Electric units are recommended.

Step 3:

Number of humidi

fi

ers for job. Divide steam

required by capacity of humidi

fi

ers at steam pressure avail-

able.

Step 4:

What size humidi

fi

er to use. For this example, a

large number of smaller capacity units is recommended.

Larger capacity units could cause condensation on the low

ceiling. Also, because of the large

fl

oor area, the humidi-

stats for fewer units would be widely spaced, which could

result in less accurate control than desirable.