7

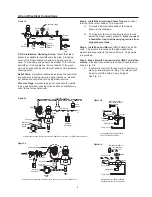

Putting the Humidifi er Into Operation

When Temperature Switch is Employed

simply set hu-

midity controller at desired level, and turn on the steam.

When Temperature Switch Is Not Employed

deactivate

operator control so that humidi

fi

er control valve will remain

closed. Then:

A. Open steam supply valve, to bring humidi

fi

er up

to

temperature.

B. When drain line from humidi

fi

er is at steam

temperature, activate the operator control.

C. Set desired relative humidity.

After the Humidifi er Is In Operation

Clean Strainer.

The screen in the strainer installed in the

steam supply line should be cleaned a few days after the

humidi

fi

er is placed in operation, and thereafter at least

once each season – more often if you

fi

nd much dirt in the

screen.

Check Trap.

The steam trap is used to drain the humidi-

fi

er should be inspected at the same time the strainer is

cleaned.

Trouble Shooting FSA, VSA

Humidifi er Will Not Discharge Steam

A. –Solenoid Fails to Open

1.

Burned

out

coil.

2.

Humidistat

at

fault.

3.

Hand

switch

open.

4. Dirt in plunger tube or bent tube.

5. Steam pressure too high for unit as

furnished.

6.

*Damaged

piston

ring.

7. *Plugged or restricted pilot ori

fi

ce.

B. -Steam System Malfunction:

1. Silencing chamber plugged with dirt.

Remove and replace silencing material and

retainer.

2.

Strainer

screen

plugged.

3. Dirt in steam line.

4. Steam valve closed in line to humidi

fi

er.

5. Pressure reducing valve out of order.

*FSA-92 and FSA-93, VSA-92 and VSA-93 only.

Humidifi er Discharge Water

A.

–Faulty

Installation:

1.

Long,

untrapped

supply

line.

2.

Humidi

fi

er supply from bottom or side of

steam

header.

3. Untrapped valve in vertical, downfeed

supply

line.

B.

–Faulty

Drainage

1.

Steam

trap

fi

lled with dirt.

2. Return line pressure above humidi

fi

er

pressure.

3. Too much vertical lift.

4. Wrong type of trap used.

5. Second trap short circuiting the

humidi

fi

er trap.

Operation and Servicing

Humidifi er Discharges Continuously, Even though

Humidity Has Reached Desired Level:

A.

–Mechanical

Trouble:

1. Humidistat fails to open (points frozen).

2. Dirt holds solenoid plunger in open position.

3. Bent solenoid tube holds plunger in open

position.

4. Dirt between valve and seat.

5.

Coil

not

de-energized.

6.

Damaged

spring.

7.

Plugged

bleed

hole.

B.

–Insuffi cient Capacity:

1. Not enough units to give desired relative

humidity.

Trouble Shooting AM, AMAF, AMEF

Humidifi er Will Not Discharge Steam

A. –Control System At Fault:

1. Faulty control valve operator.

2.

Faulty

humidity

controller.

3. Faulty connections between humidity

controller and control valve operator.

4.

Air

valve

closed.

B. –Steam System Malfunction:

1. Silencing chamber plugged with dirt.

Remove and replace silencing material and

retainer.

2. Strainer screen plugged.

3. Dirt in steam line.

4. Steam valve closed in line to humidi

fi

er.

5. Pressure reducing valve out of order.

Humidifi er Discharges Water

A. –Faulty Steam Supply:

1. Long, untrapped supply line.

2.

Humidi

fi

er supply from bottom or side of

steam

header.

3. Untrapped valve in vertical, down feed

supply

line.

4.

Boiler

carryover.

B.

–Faulty

Operation:

1. Faulty temperature switch.

2. Humidity controller set up before humidi

fi

er

has reached steam temperature.

C.

–Faulty

Operation:

1. Faulty temperature switch.

2. Humidity controller set up before humidi

fi

er

has reached steam temperature.

Humidifi er Discharges Continuously Even Though

Humidity Has Reached Desired Level.

A. –Humidity Controller Out of Calibration.

B. –Trouble in Humidifi er:

1. Valve stem “frozen” to stem seal due to

unusual chemical or corrosive conditions in

steam

system.

2.

Operator

spring

broken.

3. Dirt or scale between valve and seat.