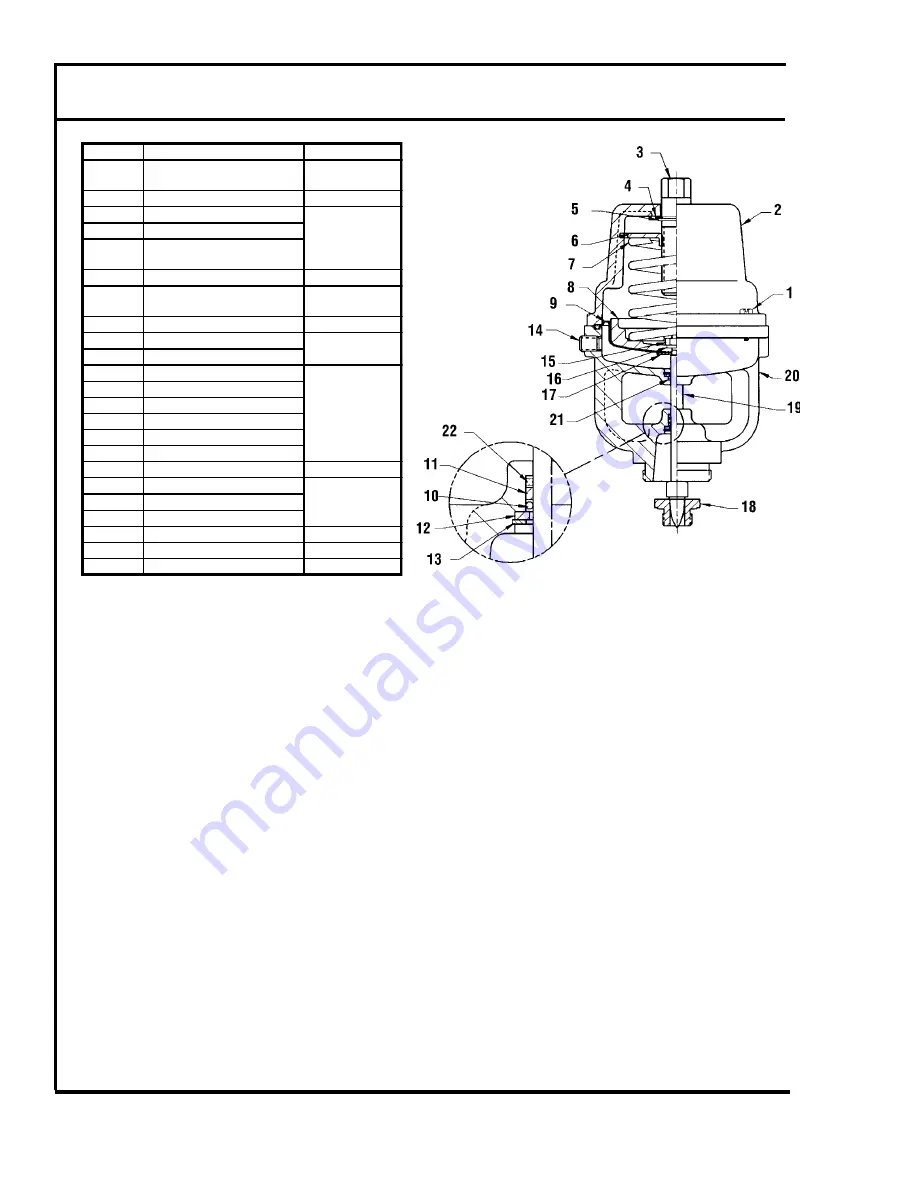

2

Repair and Adjustment Procedures for

C-1801 Pneumatic Operators

Number

Description

Part Number

1

Flange Hold Down Screws

#10-24 with washers

A-8956-A

2

Operator Cover

C-1800-C

3

Spring Adjusting Screw

A-8996 Set

4

Friction Washer

5

Spring Adjustment

Snap Ring

6

Spring Adjustment Disc

B-2358

7

Spring

A-6958 (10#)

A-6958-B (5#)

8

Piston

B-2360-C

9

Diaphragm

A-9330

17

Flat Washer

10

Spring Loaded Stem Seal

A-8991

Seal Kit

11

Brass Seal Spacer

12

Seal Retaining Washer

13

Seal Retaining Ring

21

Upper Quad Ring

22

Lower Quad Ring

14

1/8" NPT Pipe Plug

A-6000-C

19

Valve and Seat Assembly

See Chart 1130

15

Hex Nut

16

Lock Washer

18

Valve Seat

See Chart 1130

20

Operator Base (91, 92, 93)

C-1799-F

20

Operator Base (90)

C-1799-H

B. DISASSEMBLING THE ARMSTRONG C-1801 PNEUMATIC OPERATOR

Most subsequent repair procedures require disassembly of the operator.

1. Turn the spring adjusting screw (3) clockwise until it moves freely.

2. Remove the four flange screws (1).

3. Remove the operator cover (2).

4. Remove the spring adjusting screw (3), spring adjusting disc (6), snap ring (5), and fric-

tion washer (4).

5. Remove the spring (7).

C. REPLACING THE VALVE AND SEAT

ALWAYS

replace the valve and seat as a set.

1. Remove operator in accordance with Section A.

2. Using a socket wrench, remove the old valve seat (18) from the body and install a new

one.

3. Disassemble the pneumatic operator in accordance with Section B.

4. Place an

¹⁄₈

" allen wrench in the end of the valve & stem assembly (19). Hold the valve

stem in position with the allen wrench while removing the hex nut (15) with a

⁷⁄₁₆

" wrench.

5. Remove washer (16).

6. Remove valve and stem assembly (19) and replace with the new one.

7. Replace the washer (16) and the hex nut (15). Tighten the nut.

8. Assemble the operator in accordance with Section G.

Figure 2-1