North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim

armstrong

international.com

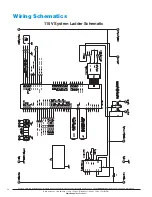

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit

armstrong

international.com for up-to-date information.

22

Only qualified personnel should perform start up procedure.

1. Examine the electrical compartment for any loose or disconnected

component wiring. Check to make sure all of the control wiring has been

completed and been done correctly.

2. Remove the top cover of the unit by unscrewing the screws holding the lid in

place. Make sure all of the Ionic Beds are fastened securely to mounting pins.

Make sure gasket is in proper position then replace top cover.

3. Check and re-check incoming voltage source and control wiring for proper

connections and tightness of connections. Verify the wiring has been done in

accordance with local codes and the enclosed wiring diagram.

4. Turn on water and check for leaks.

5. Turn on gas supply and verify that all gas piping has been checked for leaks.

(Soapy water is not recommended for use inside the control cabinet.)

6. Make sure access doors and panels are secure.

7. Power up unit at breaker. Verify Steam Generation switch is in "ON" position

See Figure 22-1.

8. The unit will begin to fill. When the water level reaches

the low level control electrode the unit will perform its

precombustion checks.

9. After the precombustion checks are done, the unit will run at

100% for a period of 5 minutes.

10. During this 5 minute period, the burner must be adjusted for

proper operation. (100% Burner Output)

11. If the unit is not properly adjusted, the unit may not operate

properly.

12. A combustion analyzer capable of detecting the CO

2

level of the combustion

gasses will be required. Combustion checks will be done at the outlet of the

vent pipe of the GFH-150 or the 1/8" NPT plugs on the top of the collection

box of the GFH-300 or GFH-450. See Figure 22-3.

13. The target for the CO

2

level will be dependent on the

type of gas used. If Natural gas is being used, the

proper CO

2

level will be between 8.5 - 9.5%. For LP

operation, the CO

2

level will need to be adjusted

between 10 - 11%.

14. Turning the adjustment screw in the clockwise direction

will decrease the level of CO

2

, and turning the

adjustment screw counter-clockwise will increase the

CO

2

level.

15. After the unit has been properly adjusted, and the 5

minute warm-up period expires, the unit will go into

normal operation.

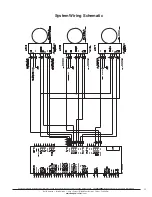

Figure 22-1

Unit Diagnostic

Power

Steam Generation

Error

Service Life

Gas Fired Humidifier

Master Reset

Steam

Off &

Tank

Drain

O

n

O

n

Steam Generation

U.S. Patent No's 5 337 703

6 070 559

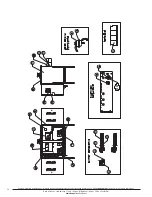

Figure 22-2

Location of

Adjustment Screw

Figure 22-3

1/8" Hole

Top View

Vent

1/8" Hole

1/8" Hole

Start Up Procedure