North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim

armstrong

international.com

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit

armstrong

international.com for up-to-date information.

9

Table 9-2. Specific Gravity Conversion Factors

Natural Gas

Propane Gas

Specific Gravity

Factor

Specific Gravity

Factor

0.55

1.04

1.50

0.633

0.60

1.00

1.53

0.626

0.65

0.962

1.60

0.612

Table 9-1. Gas Pipe Capacities

Length

of Pipe

(Feet)

Gas Flow in Piping (Cu. Ft. per Hour)

Iron Pipe Size (NPT) Inches

1/2

3/4

1

1-1/4

1-1/2

10

132

278

520

1050

1600

20

92

190

350

730

1100

30

73

152

285

590

890

40

63

130

245

500

760

50

56

115

215

440

670

60

50

105

195

400

610

70

46

96

180

370

560

80

43

90

170

350

530

90

40

84

160

320

490

100

38

79

150

305

460

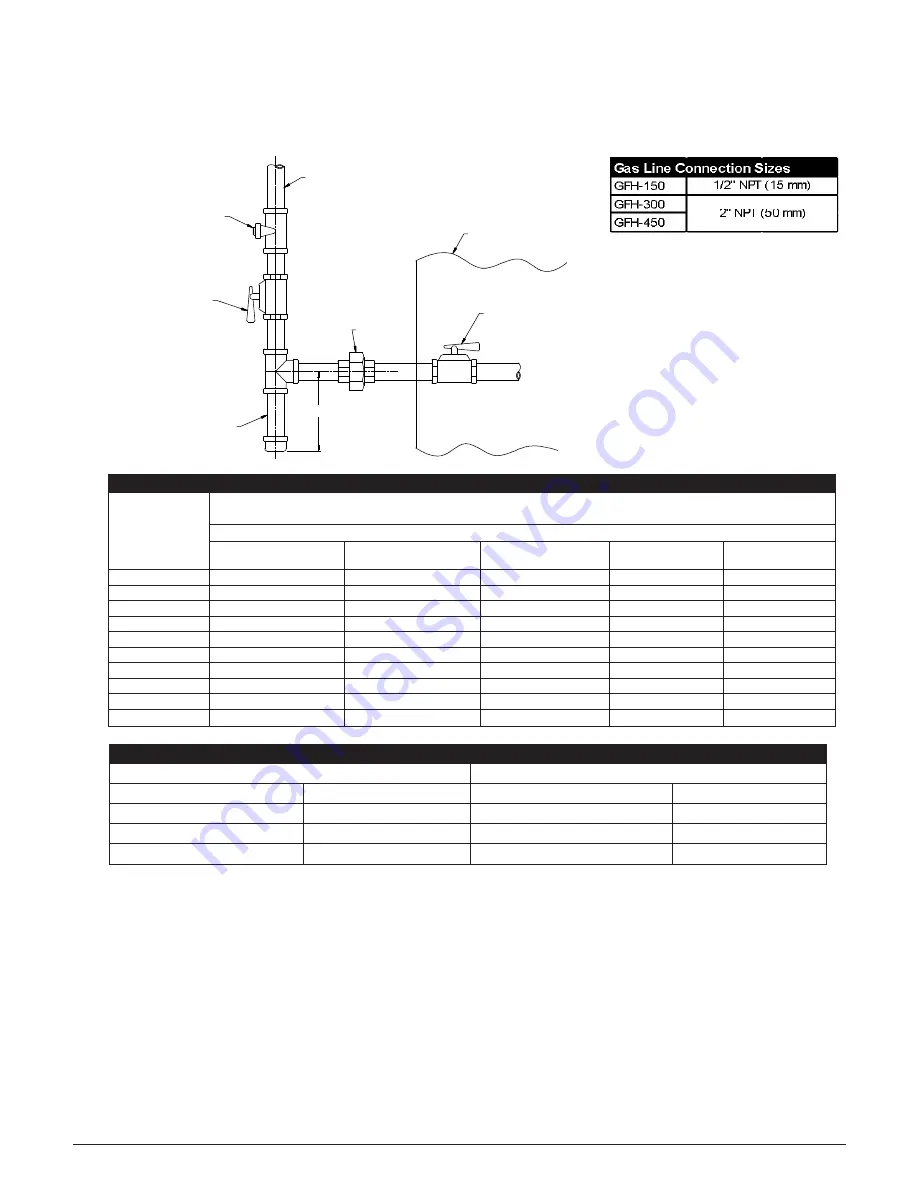

Plugged 1/8" NPT

Test Gauge Conn.

Gas Cock

Gas Supply Line

Note:

All piping and fittings

external to humidifier

supplied by others.

Drip Pocket

3" Min.

Ground Joint

Union

Humidifier Cabinet

Gas Cock

Supplied by

Armstrong International, Inc.

Figure 9-1

Allow at least 5 feet of piping between any high pressure regulator and unit pipe connection.

The physical location of the manual main shut-off valve external to the jacket when local codes require the

installation of such a valve.

Gas Leak Testing

When leak testing the gas supply piping system, the humidifier and its gas shut-off valve must be

disconnected during any pressure testing in excess of 14” WC (1/2 psi). The humidifier must

be isolated from the gas supply piping system by closing the field-installed manual shut-off valve

during any pressure testing equal to or less than 14” WC (1/2 psi).

Verify the gas supply pressure upstream of gas control unit is 7” WC on natural gas, or 11” WC on

LP Gas. Purging of gas should be performed as described in ANSI Z223.1 (latest edition) or, in

Canada, CAN/CGA-B149 codes.

Minimum Supply Pressure: 5” WC for Natural Gas and 10” WC for LP.