19

2. Check humidistat demand signal at low voltage terminal strip. It should be close or at 100%.

3. If humidifier is a three phase model, verify all three phases of power are present and equal.

4. Check amperage draw on all high voltage power lines with a clamp on amp meter. They

should be same or very close to amperage rating on the humidifier’s nameplate if the

humidistat demand is 100%.

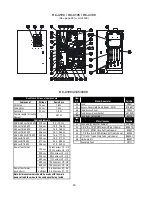

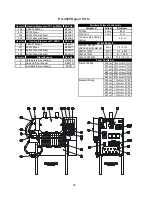

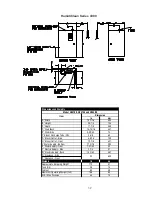

5. Turn off power. Disconnect heating elements and check resistances – see Table on

Pages 26 and 28. If an open circuit or abnormally high resistance is measured, the heating

element(s) is defective. Also, check to see if heating element leads have shorted to ground.

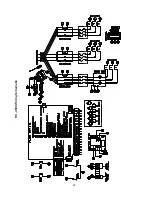

6. If heating elements are OK, check voltages at secondary side of the power module and

contactor. If no or low voltage, check primary fusing.

7. If fuses are OK, check voltage to contactor coil.

(a) If voltage is 24-28VAC at contactor coil, check coil resistance. It should be

approximately 8

Ω

with wires disconnected. If resistance is OK, check voltage

drops across the contactor.

(b) If no voltage to contactor coil, check continuity of wires from PC board to contactor.

If continuity is OK, PC board is likely defective.

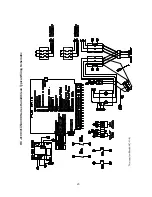

8. Check voltage signal to power module. The voltage across EC1-10 and EC1-18 (low

voltage signal to power module) should be 11-12 Vdc at 100% power.

(a) If no or low voltage, the PC board is likely defective.

(b) If voltage is OK, but green “LOAD” LED on the power module is not on, power

module is defective.

9. If green “LOAD” LED on power module is on, check voltage drops across power module.

10.If supply voltage and amperage draws are correct and elements appear OK, unit is

probably undersized (not enough capacity for the application). Check sizing or consult

factory.

Humidifier does not drain when Steam Generation is switched OFF.

1. Disconnect and check resistance of drain valve coil. Resistance should be

approximately 10

Ω

(4.1

Ω

HC-4500).

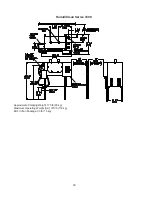

2. Make sure drain line is pitched and sized correctly. Check for blockage or obstructions

in the drain line. An air gap or funnel may be needed – See Figures 6-1 and 6-2.

3. If humidifier does not drain at specified interval or when service is to be performed and

drain valve and piping appear OK, there is blockage of the tank drain screen or the PC

board may be defective.

Dispersion tube spits water or water is present in duct

Hint: It is very helpful to cut a small observation window in the duct and cover it with plexiglass so the

steam discharge from the manifold can be observed. This way the problem can be narrowed down to

piping/steam quality (steps 1 and 2) or a condensation problem (steps 3 and 4).