9

*

Actual

switch

settings

may

vary.

See

Fig.

23-1

for

explanations

or

consult

factory.

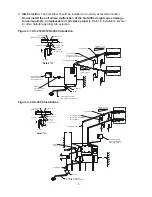

High Limit Humidistat

Remove the jumper tab from terminals 24 & 25 and wire the high limit stat between these

terminals. Refer to Figure 8-1 (the overall wiring diagram) for more information. A duct mounted

high limit humidistat is recommended to prevent over-saturation of the duct air. Use an on-off

controller that opens on fault (high humidity). Humidistat should be set for a maximum of 90%

RH. Alternately, a modulating high limit humidistat may be used on applications such as variable

air volume (VAV). Locate the high limit humidistat approximately 10’ (3m) downstream of the

dispersion manifold. If 10’ (3m) is not available, consult the factory. Note: High limit humidistat

will be wired in series with duct pressure switch, if used, see Figure 8-1.

Airflow/Pressure Switch

An airflow switch is recommended to deactivate the humidifier when there is insufficient air flow

in a duct system. A duct pressure switch is preferred as an airflow sensor. The pressure switch

should open on insufficient airflow (opens on fault). Airflow switch should be mounted in supply

air duct upstream of humidifier dispersion. Remove the jumper tab between terminals 24 and 25

and wire the airflow sensor between these terminals. See Figure 8-1 (the overall wiring diagram)

for more information. Complete installation and wiring instructions are contained in the duct

pressure switch package. Note: Duct pressure switch will be wired in series with high limit

humidistat, if used, see Figure 8-1.

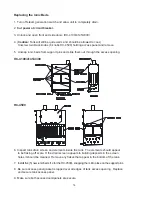

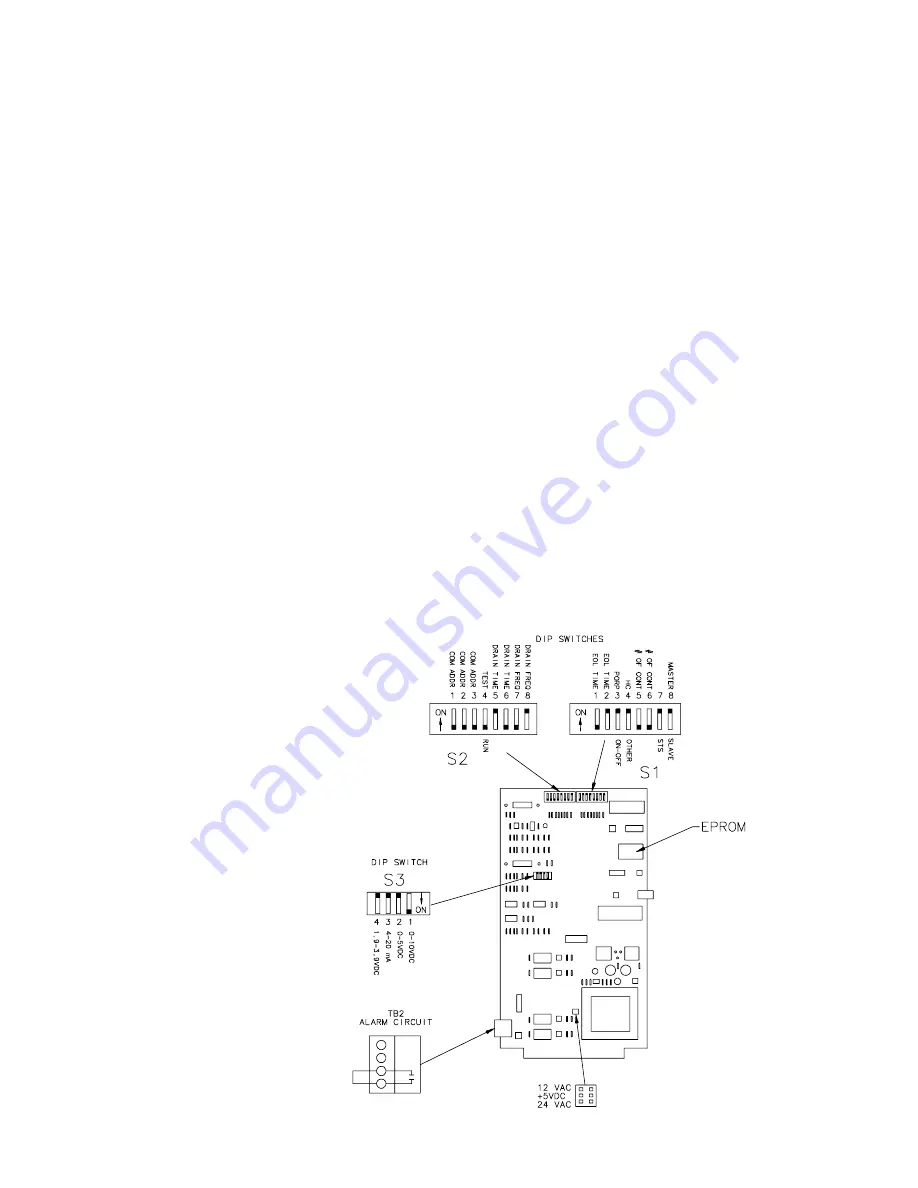

Alarm Circuit

The bottom 2 terminals on the TB2 connector on PC board, see PC Board drawing

Fig. 9-1 on Page 9, are connections for a class II NEC alarm circuit (switch closure only,

1 amp. maximum @ 24 Vdc or 0.5 amp. @ 125 Vac). The switch will close when the error or service

LED’s are energized except when high humidity/sail switch circuit is open.

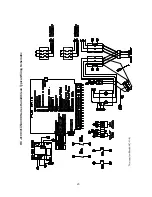

Actual

switch

setting

may

vary.

Please

see

page

8,

item

3.

Figure

9-1

PC

Board

Voltage

Source

Jumper

Please

see

Fig.

8-2

for

proper

setting.

J3

*