5

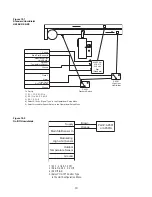

See Detail “A”

Pitch Min. 1” Per

12” Back to Unit

2” Insulated Copper

“P” Trap Drain Every

20’ of Piping or at

Bottom of Vertical Run

Pitch Min. 1” Per

12” Back to Unit

1” ID Hose

Air Gap

1” Copper (Min) Pitched

1” per 12” (Min) to

Open Drain

Water in 3/8” Copper

Type with Ball Valve

24”

Clearance

Fused Disconnector

Magnetic Breaker

within Sight of Unit

Hose Clamp

Steam Hose or Copper

Hose

Soldered Joints

1/2” or 3/8”

Copper Tube

UP

Full Size Tee

2” Copper Tee

Reducer

6” Min.

To Drain

Detail “A”

24”

See Detail “A”

Pitch Min. 1” Per

12” Back to Unit

“P” Trap Drain

Every 20’ of Piping

or at Bottom of Vertical Run

24”

2” Insulated Copper

24”

1” Copper (Min) Pitched

1” Per 12” (Min) to Open Drain

1” ID Hose

Air Gap

Fused Disconnector

Magnetic Breaker

within Sight of Unit

Water in 3/8” Copper

Type with Ball Valve

Hose Clamp

Steam Hose or Copper

Hose

Soldered Joints

1/2” or 3/8”

Copper Tube

Full Size Tee

2” Copper Tee

Reducer

To Drain

UP

Detail “A”

Figure 5-1 HC-6100/6300 Installation

Figure 5-2 HC-6500/6700 Installation

Note:

On all

HC6000 models

24” clearance is

required on both

sides and the

front of the unit.

Note:

On all

HC6000 models

24” clearance is

required on both

sides and the

front of the unit.

Summary of Contents for HumidiClean HC-6100 Series

Page 28: ...HC6100 Wye Wiring layout 28...

Page 29: ...HC6100 Delta Wiring layout 29...

Page 30: ...30 HC6100 PAR Single Phase Wiring Layout...

Page 31: ...HC6300 Wye Wiring layout 31...

Page 32: ...HC6300 Delta Wiring layout 32...

Page 33: ...HC6500 Wye Wiring layout 33...

Page 34: ...HC6500 Delta Wiring layout 34...

Page 35: ...35 HC6500 WYE 2 contactors Wiring Layout...

Page 36: ...36 HC6500 Delta 2 contactors Wiring Layout...

Page 37: ...HC6700 Wye Wiring layout 37...