Duct Steam Distribution

1. The dispersion tube should be proper length. Verify correct size from Table 8-1.

2. Install dispersion tube(s) horizontally in duct so holes face upward. Air flow must be vertical up or

horizontal. Do not restrict duct with a height of 200 mm (8”) or less. Installations over 10 m/s

(2000 FPM) air velocity are not recommended. Consult factory if air flow is vertical down or air

velocity is over 10 m/s (2000 FPM). Do not install in ducted systems with static pressure exceeding

150 mm (6”).

3. The dispersion tube(s) should be located upstream of a straight duct run, without obstructions, 3 m

(10 feet) or more in length. Consult the factory if this distance is not available.

4. Use the template provided to cut dispersion tube installation holes. Fasten the mounting plate to

duct with sheet metal screws. If the dispersion tube is 900 mm (35”) or longer, support the far

end with threaded rod or similar means.

5.

Note:

For steam being generated from a deionized (DI) or reverse osmosis (RO) water source, the

use of 50 mm (2”) insulated stainless steel piping in lieu of copper is required. Pipe used for steam

dispersion piping must be oil and contaminate free. Premature element failure could result if oils or

contaminates are present. Contact the factory with questions. Connect dispersion tube(s) to

HumidiClean tank using 50 mm (2”) nominal insulated copper pipe and hose cuffs provided. We do

not suggest steam distribution piping of field supplied rubber based compounds to be used for any

HumidiClean application. Pitch pipe back to unit 25 mm (1”) per foot. The steam pipe must be free

of kinks and sags to allow for gravity drainage of condensate. Maximum pipe run distance from

tank to dispersion tube is 12 m (40 feet) equivalent piping length. Avoid excessive use of elbows or

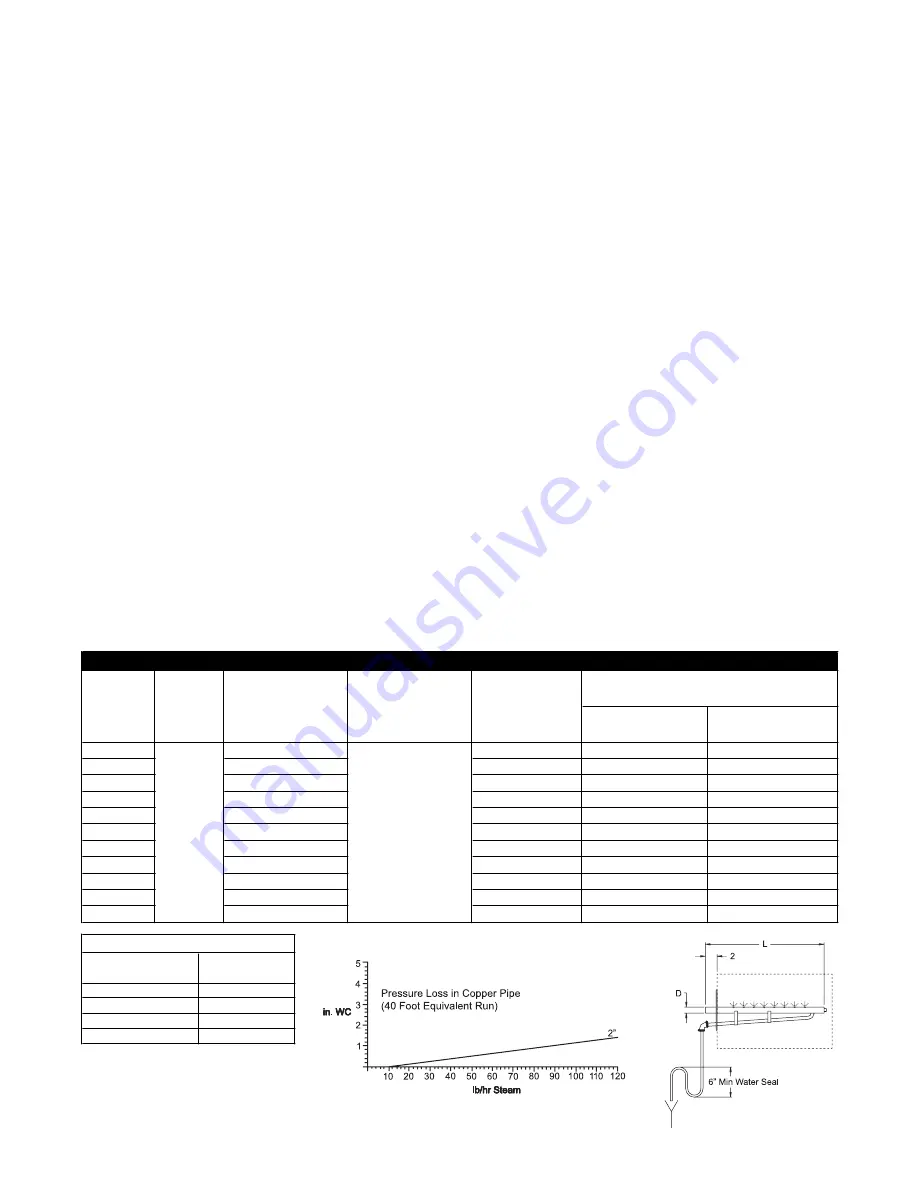

45°changes in direction. A "P" trap drain should be installed every 6 m (20 feet), of piping run or at

the bottom of vertical runs that cannot drain back to the tank. See Fig. 8-3 for "P" trap detail.

6. If duct static pressure plus piping back pressure is greater than 0.5 in HG (6" WC), please consult

the factory.

8

Figure 8-3

Figure 8-2

Minimum

mm (in)

Maximum

mm (in)

D-1

DL-1

305 (12)

280 (11)

406 (16)

D-1.5

DL-1.5

457 (18)

432 (17)

559 (22)

D-2

DL-2

610 (24)

584 (23)

864 (34)

D-3

DL-3

914 (36)

889 (35)

1168 (46)

D-4

DL-4

1219 (48)

1194 (47)

1473 (58)

D-5

DL-5

1524 (60)

1499 (59)

1778 (70)

D-6

DL-6

1829 (72)

1803 (71)

2083 (82)

D-7

DL-7

2133 (84)

2108 (83)

2388 (94)

D-8

DL-8

2438 (96)

2413 (95)

2692 (106)

D-9

DL-9

2743 (108)

2718 (107)

2997 (118)

D-10

DL-10

3048 (120)

3023 (119)

3302 (130)

Table 8-1. Dispersion Tube Length

Steam Disp. Tube

Length "L"

mm (in)

Duct Width

1-1/2"

2-3/8"

Model

HC6100,

HC6100DI

Model

HC6100,

HC6100DI

"D" Dia.

Model HC6300,

HC6300DI, HC6500,

HC6500DI, HC6700,

HC6700DI

Model HC6300,

HC6300DI, HC6500,

HC6500DI, HC6700,

HC6700DI "DL" Dia.

Table 8-1. Dispersion Tube Length

Fitting Style

Equivalent Linear

Piping (feet)

2" - 45° Elbow

2.8

2" - 90° Elbow

5.5

2" - 90° Long Elbow

3.5

2" - Tee

12

Table 8-2. Linear Piping

Summary of Contents for HumidiClean HC-6100 Series

Page 28: ...HC6100 Wye Wiring layout 28...

Page 29: ...HC6100 Delta Wiring layout 29...

Page 30: ...30 HC6100 PAR Single Phase Wiring Layout...

Page 31: ...HC6300 Wye Wiring layout 31...

Page 32: ...HC6300 Delta Wiring layout 32...

Page 33: ...HC6500 Wye Wiring layout 33...

Page 34: ...HC6500 Delta Wiring layout 34...

Page 35: ...35 HC6500 WYE 2 contactors Wiring Layout...

Page 36: ...36 HC6500 Delta 2 contactors Wiring Layout...

Page 37: ...HC6700 Wye Wiring layout 37...