6

Maintenance Requirements

High pressure drips traps should be tested at least three times per year.

When the bimetallic steam trap is suspected of malfunctioning, it can be checked by observing the discharge of the trap.

Normal trap operation would be indicated by:

• Trap discharging condensate continuously (modulating)

• Trap discharge in cycles (on-off)

All discharges are accompanied by large amounts of flash steam.

Do not confuse the discharge of flash steam with live steam loss. If the trap continues to blow live steam, isolate the trap

and repair or replace.

Troubleshooting

Whenever a trap fails to operate and the reason is not readily apparent, the discharge from the trap should be observed.

If the trap is installed with a test outlet or discharges to atmosphere, this will be a simple matter - otherwise, it will be

necessary to break the discharge connection.

1 . Cold Trap - No Discharge

No condensate or steam coming to trap.

a) Stopped or plugged strainer ahead of trap.

b) Broken valve in line to trap.

c) Pipe line or elbows plugged.

d) Pressure reducing valve out of order.

e) Isolation valves are off/closed

Caution: Superheated steam is invisible. Do not place objects directly in the path of trap discharge. In a blow through

situation a loud roar should be heard even though there may not be visible steam.

2 . Steam Loss:

If the trap leaks or blows live steam, trouble may be due to any of the following causes:

a) Valve may fail to seat

b) Piece of scale lodged in orifice

c) Worn parts

Imaginary Troubles: If it appears that steam escapes every time trap discharges, remember: Hot condensate forms flash

steam when released to lower pressure, but usually condenses quickly in the return line.

3 . Continuous Flow

A. Trap not up to temperature. Allow more time for condensate removal (on start-up).

B. On large loads the traps is working fine as designed.

If the trap is found defective:

1. Isolate the trap

2. Blow down/bleed off the internal pressure

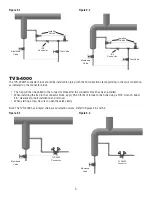

3. With the connector block in line, remove the two bolts that hold the trap to the connector block using a 9/16 wrench.

4. Remove the trap from the connector block

5. Replace the failed trap with a working trap (refer to the installation section for details on how to install)