3

Selecting and Preparing Your Site:

Before assembly, you will want to decide on

a location for your building. The best location is a level area with good drainage.

•Allow enough working space for ease of moving parts into position during assembly. Be sure there

will be enough space at entrance for doors to open fully and enough space around the building to

be able to fasten the panel screws from the outside.

•Before you begin the first steps in assembling your parts, a base should be constructed and

an anchoring system should be ready to use.

Watch the Weather:

Be sure the day you select to install your building is dry and calm.

Do not attempt to assemble your building on a windy day. Be careful on wet or muddy ground.

Teamwork:

Whenever possible, two or more people should work together to assemble

your building. One person can position parts or panels while the other is able to handle the

fasteners and the tools.

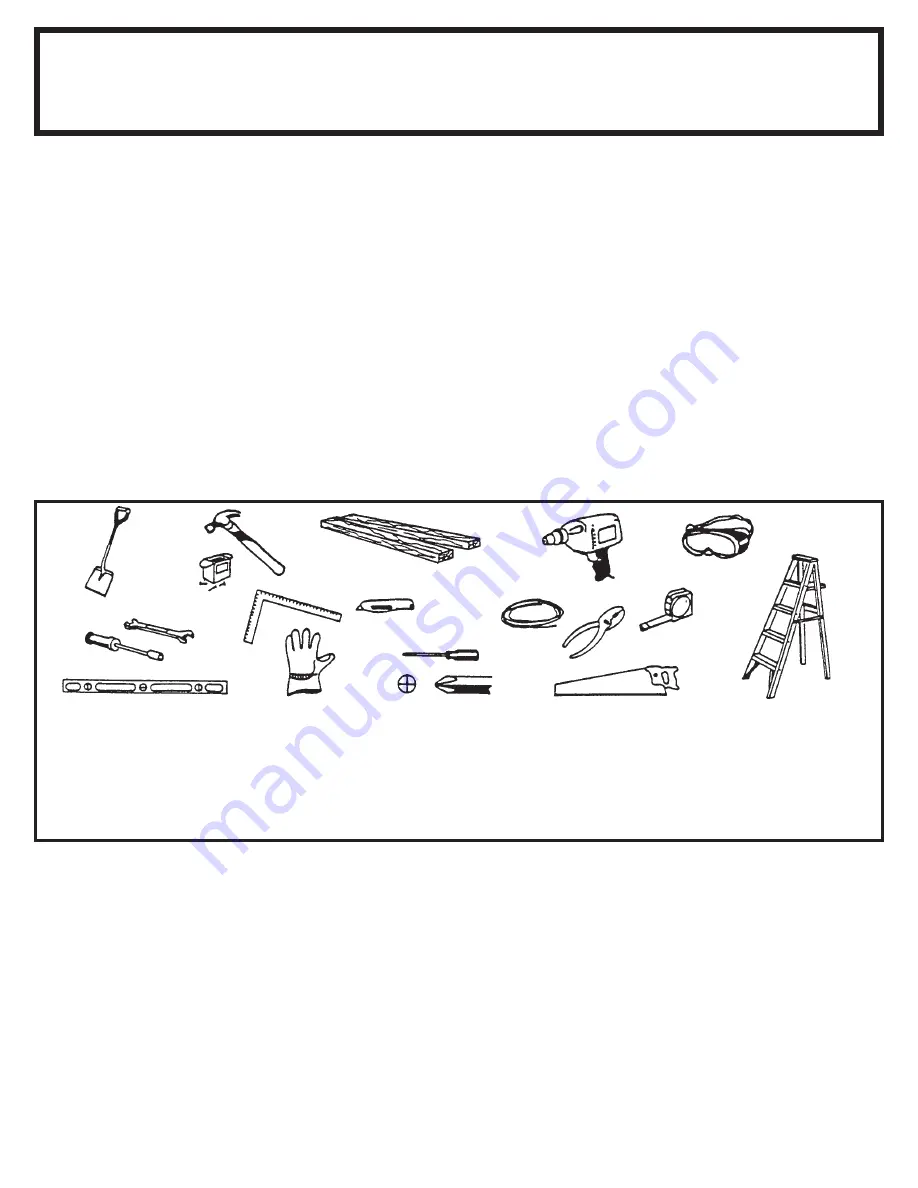

Tools and Materials:

These are some basic tools and materials you will need for the

construction of your building. Decide which method of anchoring and the type of base you

wish to use in order to form a complete list of the materials you will need.

Base Preparation

• Hammer and Nails

• Spade or Shovel

• Hand Saw / Power Saw

• Lumber and/or Concrete

Optional Time-Savers

• Wrench / Nut Driver

• Electric / Cordless Drill

• Square

• String

(for squaring frame)

Required

• Work Gloves

• Step Ladder

• Utility Knife / Scissors

• Pliers

• Carpenter's Level

• Tape Measure

Required

• Eye Goggles

• No. 2 Phillips Screwdriver

(With Hardened Magnetic Tip)

Note: A power screwdriver or vari-

able speed drill with Phillips-tip at-

tachment can speed assembly by

as much as 40%.

PLAN AHEAD....

A3