Chapter

2 –

Description

D28045104F - 02/2008

39

©

Stä

ubli

F

averg

es 2

008

2.7.

USER CIRCUIT

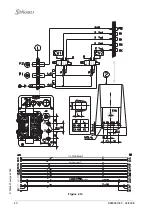

The electric wiring of the arm is assembled into a harness including several cables supplying the motors

(power, brakes, resolvers), the solenoid valves, the limit switches and user connector. These components

are connected by means of removable connectors.

The harness also includes pneumatic hoses which supply air to the solenoid valves (

EV1

and

EV2

).

The robot also has a pressure source

(

P2

)

close to the tool clamp.

The outlets of the solenoid valves

EV1

and

EV2

are on the forearm:

•

A1

and

B1

for solenoid valve

EV1

.

•

A2

and

B2

for solenoid valve

EV2

.

Figure

is for all robots except the clean room application.

Figure

is for clean room application robots.

The wiring is inside the structure and routed through the centre of the joints. It is connected to the arm base

on a plate which includes several electrical and pneumatic components such as:

Figures

•

Arm/

(1)

controller interconnection socket.

• R23

connector intended for the user for possible electrical connection of grip

(

JOC

)

.

•

Brake release selector

(3)

.

•

Brake release pushbutton

(2)

.

•

Compressed air network pneumatic (or vacuum) connections

P1

and

P2

.

•

Pneumatic (or vacuum) exhaust muffler

.

•

Arm ground connection

(4)

.

2.8.

RELEASING JOINT BRAKE

The controller must be connected to the power supply.

Place the brake release selector in position corresponding to the joint to be released.

Press the brake release pushbutton, the selected joint is totally free. When the pushbutton is released, the

brakes will then be engaged and the corresponding joint locked.

CAUTION:

When a connector is plugged to

E10

, there may be a risk of collision with the cover

(5)

in some arm configurations.

CAUTION:

Do not add wires or cables to arm wiring as this may cause premature wear of the arm

electrical wiring and lead to loss of the warranty.

CAUTION:

Make sure that the arm and load relevant to this joint are suitably supported.

Summary of Contents for RX Series

Page 2: ... Stäubli Faverges 2008 Arm RX series 90B family Instruction manual D28045104F 02 2008 ...

Page 3: ...2 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 5: ...4 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 7: ...6 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 9: ...8 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 10: ...Chapter 1 Introduction D28045104F 02 2008 9 Stäubli Faverges 2008 CHAPTER 1 INTRODUCTION ...

Page 11: ...10 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 21: ...20 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 22: ...Chapter 2 Description D28045104F 02 2008 21 Stäubli Faverges 2008 CHAPTER 2 DESCRIPTION ...

Page 23: ...22 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 25: ...24 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 2 B A C D E F 3 4 5 2 1 6 RX 90 RX 90 R ...

Page 27: ...26 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 3 Figure 2 4 ...

Page 29: ...28 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 5 ...

Page 31: ...30 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 33: ...32 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 6 ...

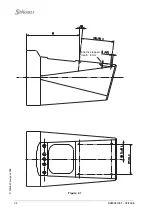

Page 35: ...34 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 7 Effective tapped depth 8 mm ...

Page 37: ...36 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 8 Figure 2 9 Figure 2 10 Figure 2 11 ...

Page 41: ...40 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 14 shielded ...

Page 43: ...42 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 15 shielded VACUUM VACUUM ...

Page 45: ...44 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 16 Figure 2 17 11 1 ...

Page 49: ...48 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 51: ...50 D28045104F 02 2008 Stäubli Faverges 2008 Figure 3 1 ...

Page 53: ...52 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 54: ...Chapter 4 Installation D28045104F 02 2008 53 Stäubli Faverges 2008 CHAPTER 4 INSTALLATION ...

Page 61: ...60 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 63: ...62 D28045104F 02 2008 Stäubli Faverges 2008 Figure 5 1 Figure 5 2 1 R 1 2 R ...

Page 65: ...64 D28045104F 02 2008 Stäubli Faverges 2008 Figure 5 3 Figure 5 4 1 2 1 2 ...

Page 67: ...66 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 69: ...68 D28045104F 02 2008 Stäubli Faverges 2008 Figure 6 1 1 1 2 3 4 6 5 7 8 9 M 2 M1 R ...

Page 71: ...70 D28045104F 02 2008 Stäubli Faverges 2008 Figure 6 2 M4 1 2 4 3 4 5 6 M3 ...

Page 73: ...72 D28045104F 02 2008 Stäubli Faverges 2008 Figure 6 3 2 1 ...

Page 75: ...74 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 77: ...76 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 1 1 1 2 2 ...

Page 79: ...78 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 2 M 2 M 2 M1 M1 1 1 2 3 A 5 7 6 4 R ...

Page 81: ...80 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 3 M 2 M 2 M1 M1 1 1 2 3 4 A 5 7 6 R ...

Page 83: ...82 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 4 M4 M4 1 3 3 4 4 2 A 5 7 6 M3 M3 ...

Page 85: ...84 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 5 M 4 1 1 2 3 4 A 5 7 6 M3 ...

Page 89: ...88 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 91: ...90 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 93: ...92 D28045104F 02 2008 Stäubli Faverges 2008 Figure 8 1 ...

Page 95: ...94 D28045104F 02 2008 Stäubli Faverges 2008 Figure 8 2 ...

Page 97: ...96 D28045104F 02 2008 Stäubli Faverges 2008 Figure 8 3 Figure 8 4 1 2 3 4 5 ...

Page 101: ...100 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 103: ...102 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 105: ...104 D28045104F 02 2008 Stäubli Faverges 2008 ...