Chapter

2 –

Description

D28045104F - 02/2008

45

©

Stä

ubli

F

averg

es 2

008

2.11.

PRESSURIZATION SYSTEM FOR DUSTY SURROUNDINGS OR SPATTERING

WITH LIQUIDS

2.11.1.

PURPOSE

For very severe applications in dusty surroundings or with spattered liquids, the objective is to keep the

pressure inside the arm above atmospheric pressure in order to avoid migration of dust and liquids.

2.11.2.

INSTALLATION

a)

Plate with pneumatic system

P3

:

•

Use this fitting to connect the unit.

b)

Plate without pneumatic system

P3

:

•

If the hose

(P2)

between

(9)

and

(10)

is not used, cut the pipe

(P2)

at

(9)

and plug

(P2)

at

(10)

.

•

If

(P2)

is used for another function, add a pressure sealed union to the connector mount (black plate at

base of arm to which the electrical connector is attached).

•

Attach the unit with

4

screws (

Ø 6

max.) at item

(8)

(screws not supplied) to a rigid vertical wall in direction

shown by arrow; the air inlet

(1)

being to the left of the regulator

(2)

.

•

Provide for air inlet at

(1)

, this is a

G1/4

tapped hole; the air pressure is

10 bar

maximum. Before the

pressure arrives at

(1)

, make sure that the regulator

(2)

is completely screwed out and that the valve

(3)

is completely screwed in. Before pressurizing the arm, also make sure that the arm is correctly connected

and correctly sealed (covers closed, plugs in hoisting ring tapped hole, pipe connected at

(6)

and at

(9)

,

etc.).

•

Install a pipe with an outside

Ø 8

between the unit (output

6

) and the arm (input

P2

). Provide a male

G1/

4

union for the pipe with an outside

Ø 8

. At

(P2)

, the hole is a

G1/4

tapped hole for the complete

RX

range.

•

Pressurize the arm.

1)

Slowly screw in the regulator. First adjust the pressure to

1 bar

max. (pressure shown on pressure

gage

11

).

Note:

At this stage, the low pressure gage

(5)

must remain at

0 mbar

.

2)

Very slowly screw out the valve

(3)

;

the value on the pressure gage

(5)

must increase

progressively. When this value reaches

5

to

10 mbar

and remains stable, adjustment is

considered as correct.

•

If however the valve

(3)

is completely screwed out and it is impossible to reach

5 mbar

, check that:

a)

The circuit is tight (unit, arm, pipe, etc.)

b)

The pressure gage

(5)

is not unserviceable (damaged by a pressure greater than

40 mbar

).

If the

2

points

a

and

b

are correct, the pressure can be increased by means of the

(2)

regulator without

however exceeding

2 bar

.

Note:

It is preferable for safety reasons (valve

4

opens between

15

and

25 mbar

s) and

consumption reasons to work with minimum pressures (high and low pressures).

CAUTION:

The overpressure must never exceed

20 mbar

.

CAUTION:

An excessive value (above

40 mbar

) will make the pressure gage

(5)

unusable.

Summary of Contents for RX Series

Page 2: ... Stäubli Faverges 2008 Arm RX series 90B family Instruction manual D28045104F 02 2008 ...

Page 3: ...2 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 5: ...4 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 7: ...6 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 9: ...8 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 10: ...Chapter 1 Introduction D28045104F 02 2008 9 Stäubli Faverges 2008 CHAPTER 1 INTRODUCTION ...

Page 11: ...10 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 21: ...20 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 22: ...Chapter 2 Description D28045104F 02 2008 21 Stäubli Faverges 2008 CHAPTER 2 DESCRIPTION ...

Page 23: ...22 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 25: ...24 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 2 B A C D E F 3 4 5 2 1 6 RX 90 RX 90 R ...

Page 27: ...26 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 3 Figure 2 4 ...

Page 29: ...28 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 5 ...

Page 31: ...30 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 33: ...32 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 6 ...

Page 35: ...34 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 7 Effective tapped depth 8 mm ...

Page 37: ...36 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 8 Figure 2 9 Figure 2 10 Figure 2 11 ...

Page 41: ...40 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 14 shielded ...

Page 43: ...42 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 15 shielded VACUUM VACUUM ...

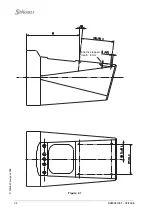

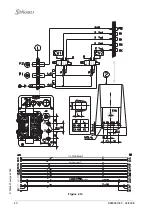

Page 45: ...44 D28045104F 02 2008 Stäubli Faverges 2008 Figure 2 16 Figure 2 17 11 1 ...

Page 49: ...48 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 51: ...50 D28045104F 02 2008 Stäubli Faverges 2008 Figure 3 1 ...

Page 53: ...52 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 54: ...Chapter 4 Installation D28045104F 02 2008 53 Stäubli Faverges 2008 CHAPTER 4 INSTALLATION ...

Page 61: ...60 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 63: ...62 D28045104F 02 2008 Stäubli Faverges 2008 Figure 5 1 Figure 5 2 1 R 1 2 R ...

Page 65: ...64 D28045104F 02 2008 Stäubli Faverges 2008 Figure 5 3 Figure 5 4 1 2 1 2 ...

Page 67: ...66 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 69: ...68 D28045104F 02 2008 Stäubli Faverges 2008 Figure 6 1 1 1 2 3 4 6 5 7 8 9 M 2 M1 R ...

Page 71: ...70 D28045104F 02 2008 Stäubli Faverges 2008 Figure 6 2 M4 1 2 4 3 4 5 6 M3 ...

Page 73: ...72 D28045104F 02 2008 Stäubli Faverges 2008 Figure 6 3 2 1 ...

Page 75: ...74 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 77: ...76 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 1 1 1 2 2 ...

Page 79: ...78 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 2 M 2 M 2 M1 M1 1 1 2 3 A 5 7 6 4 R ...

Page 81: ...80 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 3 M 2 M 2 M1 M1 1 1 2 3 4 A 5 7 6 R ...

Page 83: ...82 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 4 M4 M4 1 3 3 4 4 2 A 5 7 6 M3 M3 ...

Page 85: ...84 D28045104F 02 2008 Stäubli Faverges 2008 Figure 7 5 M 4 1 1 2 3 4 A 5 7 6 M3 ...

Page 89: ...88 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 91: ...90 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 93: ...92 D28045104F 02 2008 Stäubli Faverges 2008 Figure 8 1 ...

Page 95: ...94 D28045104F 02 2008 Stäubli Faverges 2008 Figure 8 2 ...

Page 97: ...96 D28045104F 02 2008 Stäubli Faverges 2008 Figure 8 3 Figure 8 4 1 2 3 4 5 ...

Page 101: ...100 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 103: ...102 D28045104F 02 2008 Stäubli Faverges 2008 ...

Page 105: ...104 D28045104F 02 2008 Stäubli Faverges 2008 ...