161

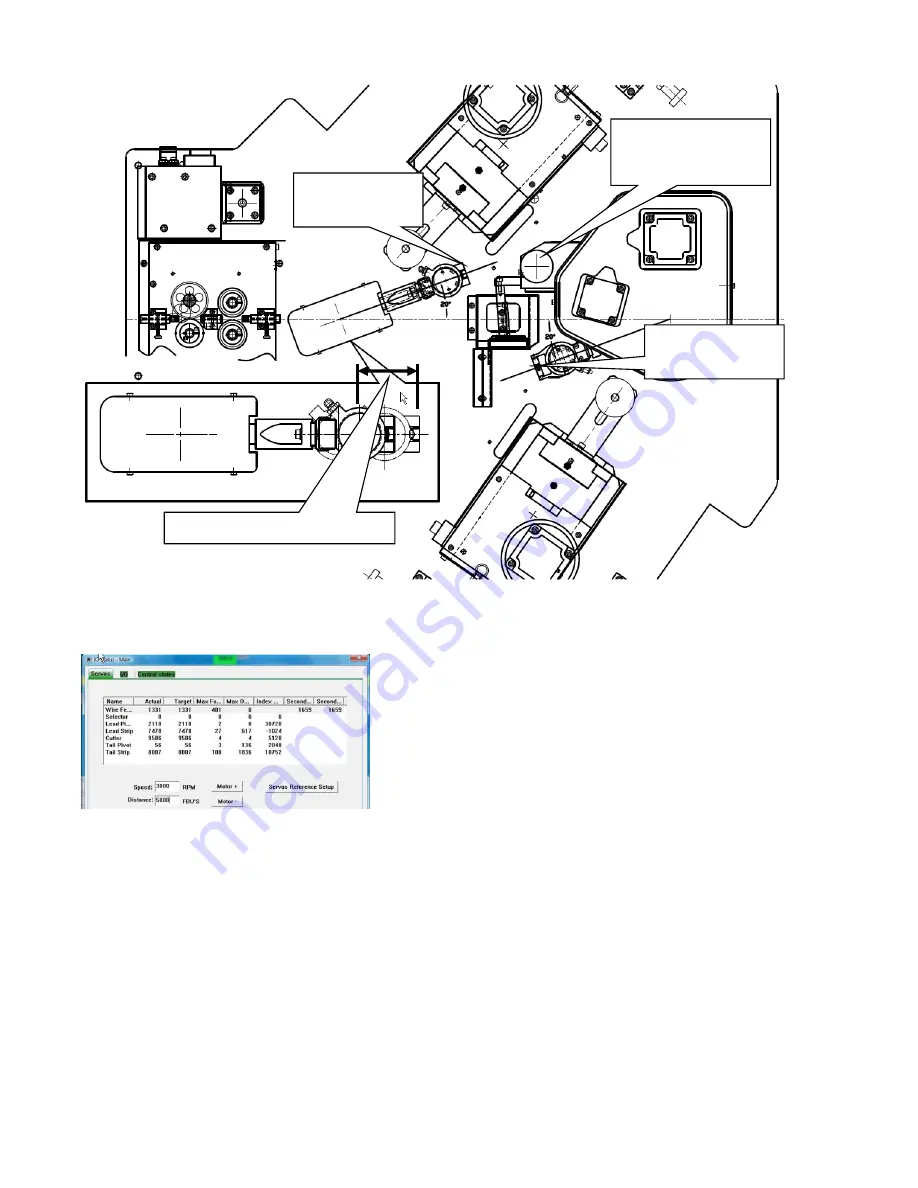

When the mechanical position is set, the motor marker pulse (index data) needs to be set.

Open the

IO

screen. View the Servo tab.

.

Rotate the respective motor until the Index value changes. Rotate it

in the opposite direction until the index changes again. Turn the

knob back and forth observing the index value. Center the rotation

on the index mark with the minimum of motion. Now, replace the

belt and tighten properly.

Proper Belt Tension:

Adjust the belt until the free play is gone

(minimum defection) but the belt is not STRETCHED.

SETTING THE “SERVO REFERENCE”

After you have set the

Mechanical Index Position,

the servo reference must be set. This is done using the

Master Reference Fixture

. This is placed in the cutter head and the pivot arms are positioned in it to set the

starting position.

If you are using the old reference fixture:

Place the

Master Reference Fixture 5-144860

in the cutter head. Close the cutter head and place the pivot

arms into it.

Infeed pivot at

approx. 20°

Outfeed pivot at

approx. 20°

10mm back from fully

Cutter, rotate fully

CW to stop, then

back ½ rotation