65

Crimp Height Core

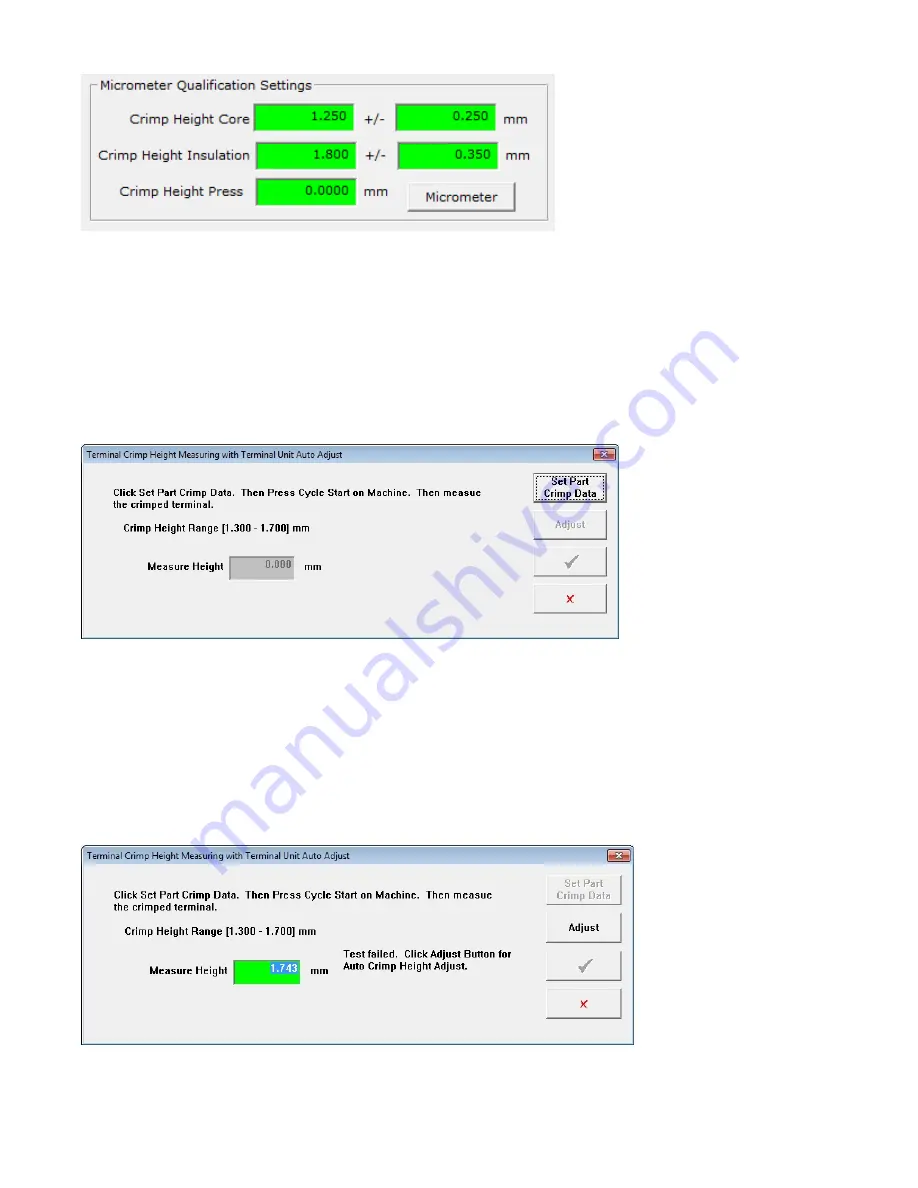

- This is the required height measurement for the core crimp and the tolerance allowed.

Entering a 0 in this field indicates that you do not wish to qualifiy this measurement, if qualification is enabled on

the machine.

Crimp Height Insulation

– This is the required height measurement for the insulation crimp and the tolerance

allowed. Entering a 0 in this field indicates that you do not wish to qualifiy this measurement, if qualification is

enabled on the machine.

Crimp height press

– See section “Cross Section and Crimp Height” above.

Micrometer –

Click on this will open a window so you can see the data being sent from the micromer, if a

micrometer is installed on the machine.

Using micrometer to set crimp height

To check the Crimp Height Core, click on the Micrometer button and window below will appear.

If you do not already have a part made, click

Set Part Crimp Data

. Then press

Cycle Start

on Machine.

Measure the crimped terminal and press the orange button on the Micrometer to automatically transfer the

measurement to the screen.

If the test passes you can choose to green check box to exit the screen. If the machine has automatic crimp

height you can choose to optimize the crimp height by clicking the Adjust button. This will move the crimp height

mechanism by the distance of measured height verses the Crimp Height Core dimension programmed in the

crimping settings screen.

If the

Measure Height

is out of the

Crimp Height Range

, the Micrometer test will

FAIL

.

If the crimp height fails you need to make necessary changes to the Applicator. If the machine is equipped with

Automatic crimp height adjust you can have the machine change the crimp height, by clicking the Adjust

button. This will move the crimp height mechanism by the distance of measured height verses the Crimp Height