85

During the CFM process the system will inspect all crimps. A crimp can fail in two ways.

Sigma Failure:

This failure falls outside of a sigma limit variance. These failures are destroyed and remade. If it fails,

again the machine will stop.

Gross Failure:

This failure falls outside of maximum limits. A gross failure will stop the machine immediately.

Gross failures are usually caused by missing terminals, wire or broken tooling.

Do not restart the machine until the cause is identified and corrected

Mainenance

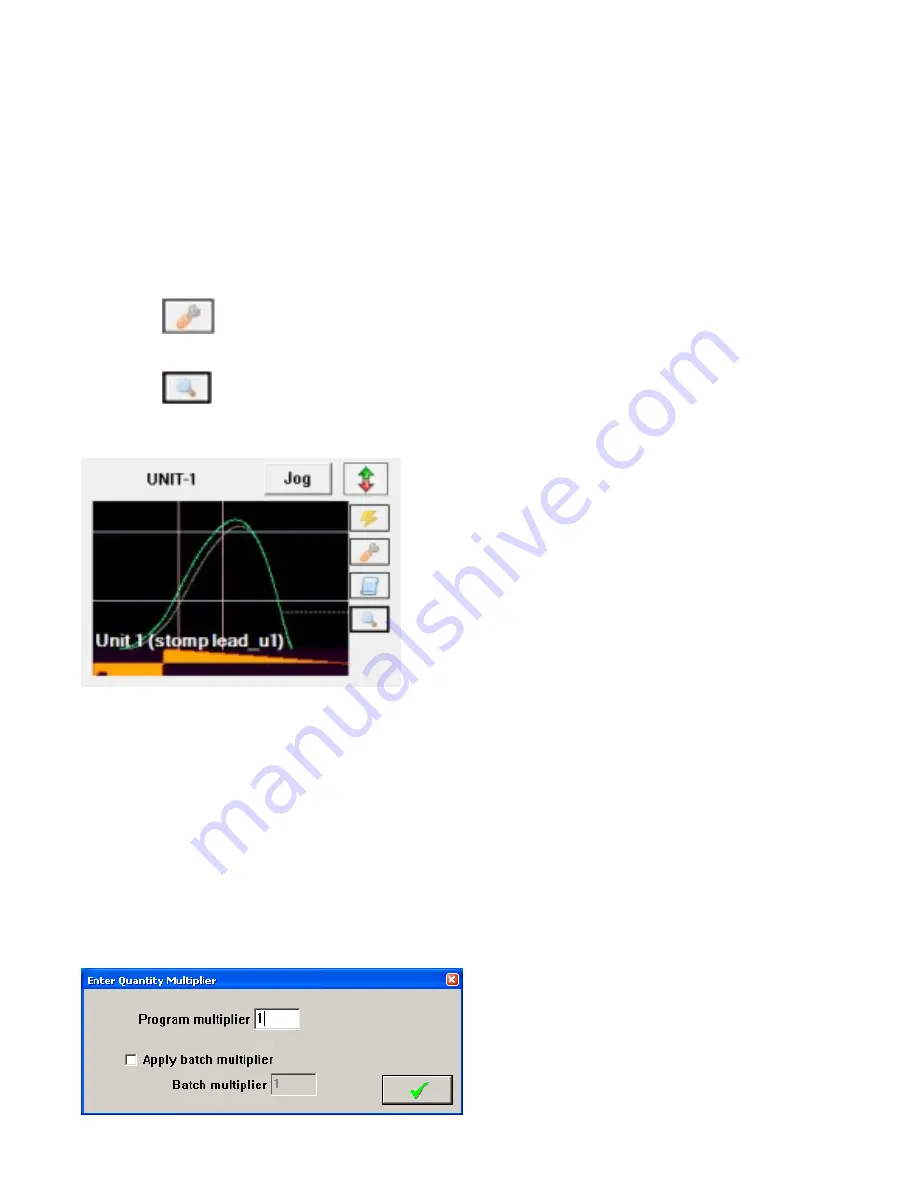

Clicking the

will open the Forceview configuration screen.

Open Forceview

Clicking the

will open the Forceview screen. In this screen you can see a full size image of the curves

and trending data. To return from the Force view screw click Popup Mode in the main menu bar of

Forceview.

Creating and Editing Job Programs

The CR11 can be programmed to run a Job Program. This is a series of existing part programs run either in a

batch or harness.

A maximum of 500 parts can be entered on a job list.

There are two modes to run the

machine, Batch and Harness, both are described below.

Batch Mode

will produce all the parts programmed in the total quantity of a part program in the batch sizes

desired and will then change to the next programmed part. The quantities of wires to be produced can be pre-

programmed in the job list or they can be entered at run time. If you want to pre-program the number of wires to

be produced simply enter the Total number and Batch number on the list. When you start to run a job program in

the software you will be given the following message. Make sure the Program multiplier is set for 1 and click the

green check to use the pre-programmed quantities.