PREPAIRING THE GRINDER MIXER FOR OPERATION

15

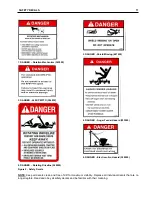

PREPAIRING THE GRINDER MIXER FOR OPERATION

Remove the shipping banding or wire from the

auger feeder (if equipped), rear discharge cover

and the unloading tube to saddle at the side of the

tank.

IMPORTANT:

Remove

the

bag

from

the

supplement hopper. Place the screen hook in the

hammer mill door pin (See Figure 9).

Figure 9 - Screen Hook Storage.

Install the PTO driveline storage bracket under the

front hitch with 1/2 inch x 1-1/2 inch bolt and lock

nut (See Figure 10). Maintain tension with the lock

nut to allow movement with 15 lbs. pull.

Figure 10 - PTO Driveline Storage Bracket.

Refer to OPERATION OF GRINDER MIXER

–

Auger Feeder Operation.

Install any option that was ordered with the grinder

mixer and shipped as loose equipment. See

instructions packaged with the specific options for

installation.

Install the implement end of the PTO driveline by

fastening it to the input jackshaft with the 5/16 inch

x 3-1/2 inch clevis pin and cotter pin provided.

Spread the cotter pin and make sure the proper

PTO is used.

CAUTION: NEVER OPERATE A 540 RPM

GRINDER MIXER WITH A 1000 RPM

TRACTOR.

If equipped with a bolt-on extension, hydraulic

auger feeder, or roll feed, refer to OPERATION OF

GRINDER MIXER

Auger Feed Operation sections as well as the

ATTACHMENTS section for instructions.

T

IRES

Keep tires properly inflated. Lack of pressure can

result in torn valve stems, fabric breaks and uneven

tread wear. Too much pressure can cause undue

strain on fabric, excessive tread wear and allows

the tire to cut in more on wet surfaces. Equal tire

pressure reduces grinder mixer sway when towing.

Recommended tire inflation pressure is as follows:

9.5L x 15

8

– ply tires – 44 psi

G

UARDS

,

D

OORS

,

A

ND

S

HIELDS

Make sure that all of the guards, doors, and shields

are in place and functioning.

B

OLTS

A

ND

N

UTS

Cap screws, except for shear bolts, used on the

grinder mixer are Grade 5 and if replaced, cap

screws of equal or greater strength should be used.

Grade 5 cap screws are identified by three radial

dashes on the hex head. Refer to the SAE bolt

identification guide (See Figure 11).

Figure 11 - SAE Bolt Identification.

IMPORTANT:

Shear bolts must be replaced with

bolts of the same grade

Before operation of the grinder mixer, make sure all

bolts and nuts are properly tightened. Make sure all

cotter pins are spread and not damaged. After

operation of the grinder mixer for several hours,

make sure all bolts are set to proper torque. Refer

to the torque guide (See Table 1).