Product Manual

SECTION 1

VIRTUOSO 5460F

115057 REV L

4

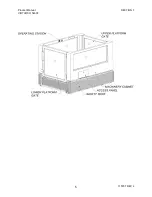

1.2 Terminology

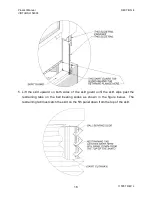

To effectively use this manual, you need to be familiar with the following terms. Refer to

the figure on the following page for identification of components. Not all components

are shown in the figure.

Access Panel

The hinged panels (four total) that provide access to the machinery

cabinets.

Back End

The upper landing end of the lift.

Base

The steel frame that rests on the floor and supports the operating mechanism.

Front End

The end of the lift where the lower platform gate is located.

Lift Car

The compartment in which the passenger rides. Commonly called the

"platform" in the lift industry.

Lower Platform Gate

The gate that serves the lower landing (ground level).

Machinery Cabinet

The enclosures in which the lifting mechanism is located. There is

one cabinet on each side of the lift. The contents of the machinery cabinets are

accessible through the access panels.

Operating Stations

The controls for raising and lowering the lift car. The operating

station inside the lift car has an emergency stop switch. The operating station outside

the lift car may be remotely mounted.

Safety Skirt

The accordion-style cover which completely encloses the underside of the

lift car.

Upper Landing

The stage, platform, or riser that the lift serves.

Upper Platform Gate

The gate that serves the upper landing, or stage. The lift may

also have an upper landing gate mounted to the upper landing sill that opens in tandem

with the upper platform gate.

Summary of Contents for VIRTUOSO 5460F

Page 2: ......

Page 3: ...ASCENSION VIRTUOSO WHEELCHAIR LIFT 5460F MODEL SERIES PRODUCT MANUAL...

Page 11: ...Product Manual SECTION 1 VIRTUOSO 5460F 115057 REV L 5...

Page 34: ...Product Manual SECTION 4 VIRTUOSO 5460F 115057 REV L 28...

Page 45: ...Product Manual SECTION 5 VIRTUOSO 5460F 115057 REV L 39...

Page 53: ...Product Manual Notes VIRTUOSO 5460F 115057 REV L 47 Notes...

Page 54: ...Product Manual Notes VIRTUOSO 5460F 115057 REV L 48 Notes...

Page 55: ......