Maintenance & Repair Manual

SECTION 3

VIRTUOSO 5460P

9

110057 REV K

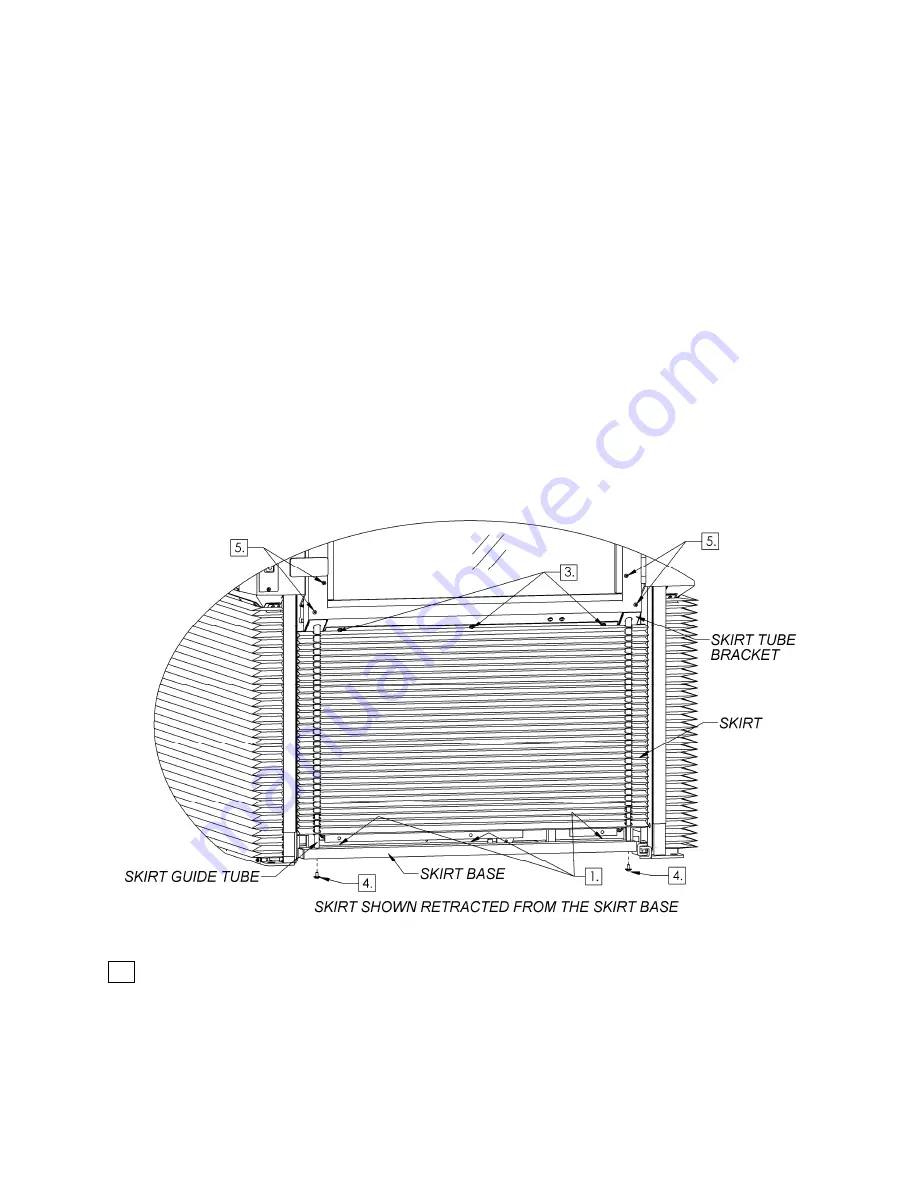

3.4 Retracting, Removing, and Reinstalling the Safety Skirt

The safety skirt consists of two parts: the lift car skirt, which guards the lift car on three

sides; and the gate skirt, which guards the area under the lower landing gate. For some

of the repairs described in this manual, it is necessary to gain access to components

normally hidden behind the skirt. In most cases, only a small portion of the skirt may

need to be retracted; however, sometimes it may be necessary to remove the whole

skirt.

To remove the

gate skirt

, perform all of the following steps. If the skirt only needs to be

retracted, performing only Step 3 will provide access to many of the components behind

the skirt. Refer to the figure below for the location of the fasteners referenced in each

step.

1.

Use a 5/16" wrench to remove the three (3) hex head screws that secure the skirt

to the skirt base. These screws are located on the top side of the skirt base.

2.

Using any operating station, raise the lift car until the car floor is approximately

24" off the ground.