Maintenance & Repair Manual

SECTION 3

VIRTUOSO 5460P

21

110057 REV K

The upper stop mechanism has four (4) adjustable components: the transport switch,

the stop switch, the two-inch switch, and the ball plunger. See the figure on the

previous page for identification of these components. These four (4) components must

be adjusted so that the following four (4) conditions are met:

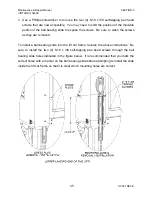

1.

The stop switch roller is actuated by the actuator ramp at the same time that the ball

plunger "clicks" into the plunger slot.

For fine adjustments to the stop switch, use a

1/16" hex key to adjust the set screw at the lever base. For gross adjustments to the

stop switch, use a 5/64" hex key to turn the two (2) 6-32 x 1-1/4 mounting screws.

Or, to adjust the ball plunger mounting bracket, use a 1/8" hex key to turn the two (2)

10-32 x 3/4 screws. After adjusting the ball plunger mounting bracket, the two-inch

switch may need to be readjusted as well (see item 2 below).

2.

The two-inch switch is actuated whenever the lift car is less than two inches off the

ground.

To adjust the two-inch switch, use pliers and/or a 5/8" wrench to move the

nuts on the barrel of the switch. To check the adjustment of the 2" switch, return the

lift car to the ground. Then:

a. With the lower landing gate open, depress the lower landing gate switch (refer

to Section 3.9), and raise the lift car by holding an operating switch "Up". If

the lift car does not stop before it has moved 2" off the ground, the body of the

switch needs to be adjusted further from the mounting bracket.

b. With the lower landing gate closed, hold an operating switch "Up" to raise the

lift car off the ground. If the lift car stops or "jumps" within 4" of the ground,

the body of the switch needs to be adjusted closer to the mounting bracket.

3.

The transport switch is actuated whenever the height adjustment knob is in the

"TRANSPORT" position.

To adjust the transport switch, use pliers and/or a 5/8"

wrench to move the two (2) nuts on the barrel of the switch.

4. The ball plunger has a positive engagement with the plunger slot.

To adjust the

strength of the "click" that is felt when the ball plunger engages the plunger slot, use

a 3/4" wrench to loosen the 1/2-13 nut and then turn the ball plunger with a standard

screwdriver. Turn the ball plunger clockwise to make the "click" stronger or

counterclockwise to make the "click" weaker.