Ascon Tecnologic - Z31V - OPERATING INSTRUCTIONS - PAG. 3

3. USAGE WARNINGS

3.1

Admitted use

m

The instrument has been projected and manufactured

as a measuring and control device to be used accord-

ing to EN61010-1 at altitudes operation below 2000 m.

Using the instrument for applications not expressly permitted

by the above mentioned rule must adopt all the necessary

protective measures.

The instrument

must not be used

in dangerous environ-

ments (flammable or explosive) without adequate protections.

m

The installer must ensure that the EMC rules are

respected, also after the instrument installation, if

necessary using proper filters.

4. INSTALLATION WARNINGS

4.1

Mechanical mounting

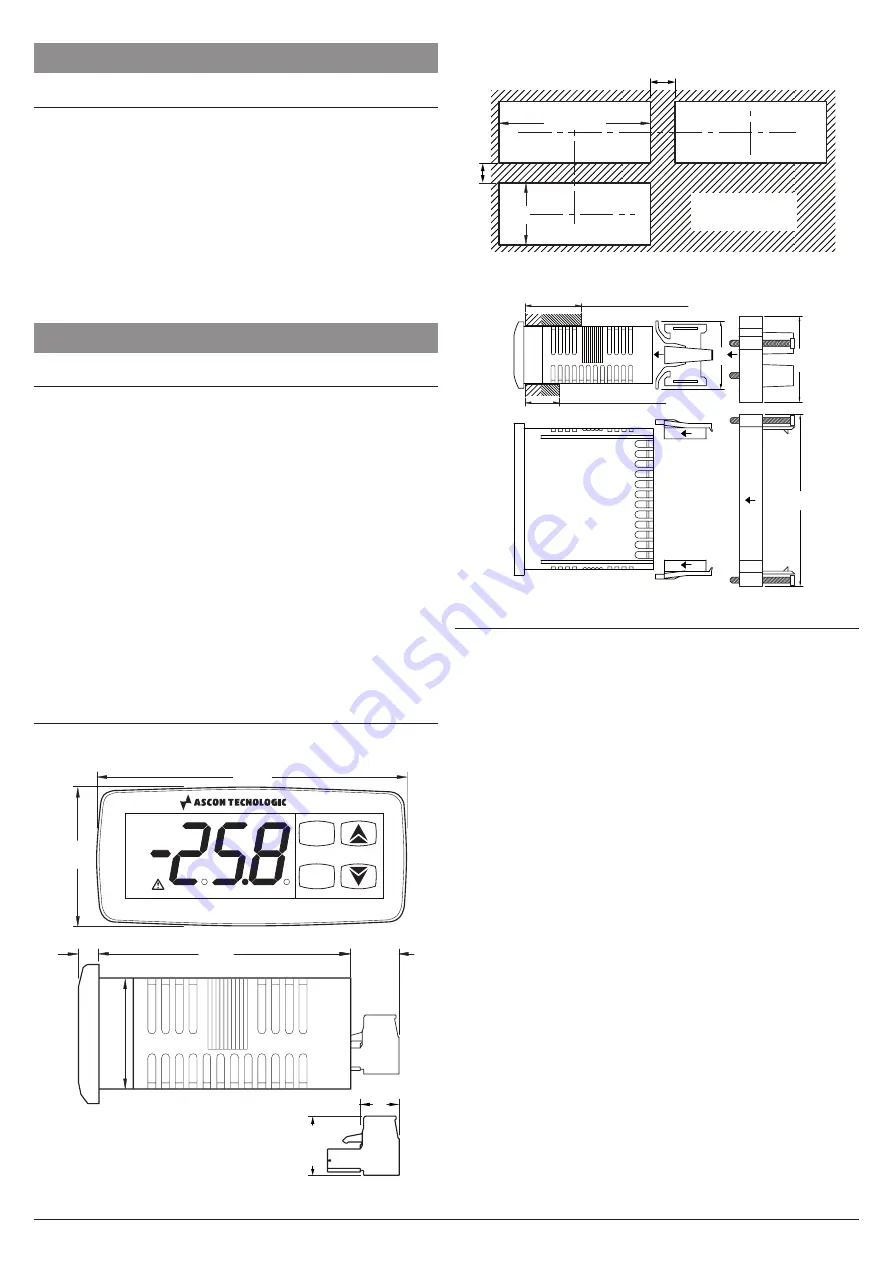

The instrument, in case 78 x 35 mm, is designed for flush-

in panel mounting. Make a 71 x 29 mm hole and insert the

instrument, fixing it with the provided special brackets.

To obtain the declared front protection degree please use the

optional screw type bracket.

–

Avoid installing the instrument in places with high humidity

which can generate condensation or with dirt which can

lead to the introduction of conductive substances into the

instrument.

–

Ensure the adequate ventilation to the instrument and avoid

the installation within boxes where are placed devices which

may overheat or have, as a consequence, the instrument

functioning at temperature higher than allowed and declared.

–

Connect the instrument as far as possible from source of

electromagnetic disturbances so as motors, power relays,

relays, electrovalves, etc..

4.2

Dimensions

[mm]

4.2.1

Mechanical dimensions

P

U

Z31V

35

78

28

12.2

14.5

8

6

64

4.2.2

Panel cut-out

29

+0.6

71

+0.6

mm

RECOMMENDED

PANEL CUTOUT

min.

12 mm

min. 15 mm

4.2.3

Mounting

[mm]

Type 2: gasket max. 12 mm

Type 1: gasket 29 mm max.

34

43

Type 2

Type 1

“Butte

rf

ly” type

bracket

s

Screw type

bracket

86

4.3

Electrical connections

Carry out the electrical wiring by connecting only one wire to

each terminal, according to the following diagram, checking

that the power supply is the same as that indicated on the

instrument and that the load current absorption is no higher

than the maximum electricity current permitted.

As the instrument is built-in equipment with permanent con-

nection inside housing, it is not equipped with either switches

or internal devices to protect against current overloads: the

installation will include an overload protection and a two-

phase circuit-breaker, placed as near as possible to the in-

strument and located in a position that can easily be reached

by the user and marked as

instrument disconnecting

device

which interrupts the power supply to the equipment.

Further recommendations:

–

The supply of all the electrical circuits connected to the

instrument must be properly protected using devices (ex.

fuses) proportionate to the circulating currents;

–

Use cables with proper insulation, according to the working

voltages and temperatures;

–

Make sure that the input sensor cables are kept separate

from line voltage wiring in order to avoid induction of elec-

tromagnetic disturbances;

–

If some cables are shielded, the protection shield must be

connected to ground at only one side;

–

If the instrument has a 12/24 V power supply (Order Code

a

=

F

/

G

), it is recommended to use an external TCTR

transformer, or an equivalent transformer with a Class II

Insulation, and to use a transformer for each instrument

because there is no insulation between supply and input.