Ascon Tecnologic - KX Line - ENGINEERING MANUAL -Vr.4.0

PAG. 25

The letter will change from

A

to

o

and vice versa.

10. Select the second parameter that you want to add to the

assistance level and repeat step 6, 7 and 8.

11. Repeat step 5, 6, 7, 8 until the list has been completed.

12. When you need to exit from promotion procedure, push

button and maintain the pressure for more than 10 s.

The instrument will show the “standard display”.

Note:

When you set the some number to two parameter, the

instrument will use only the last programmed parameter.

Example:

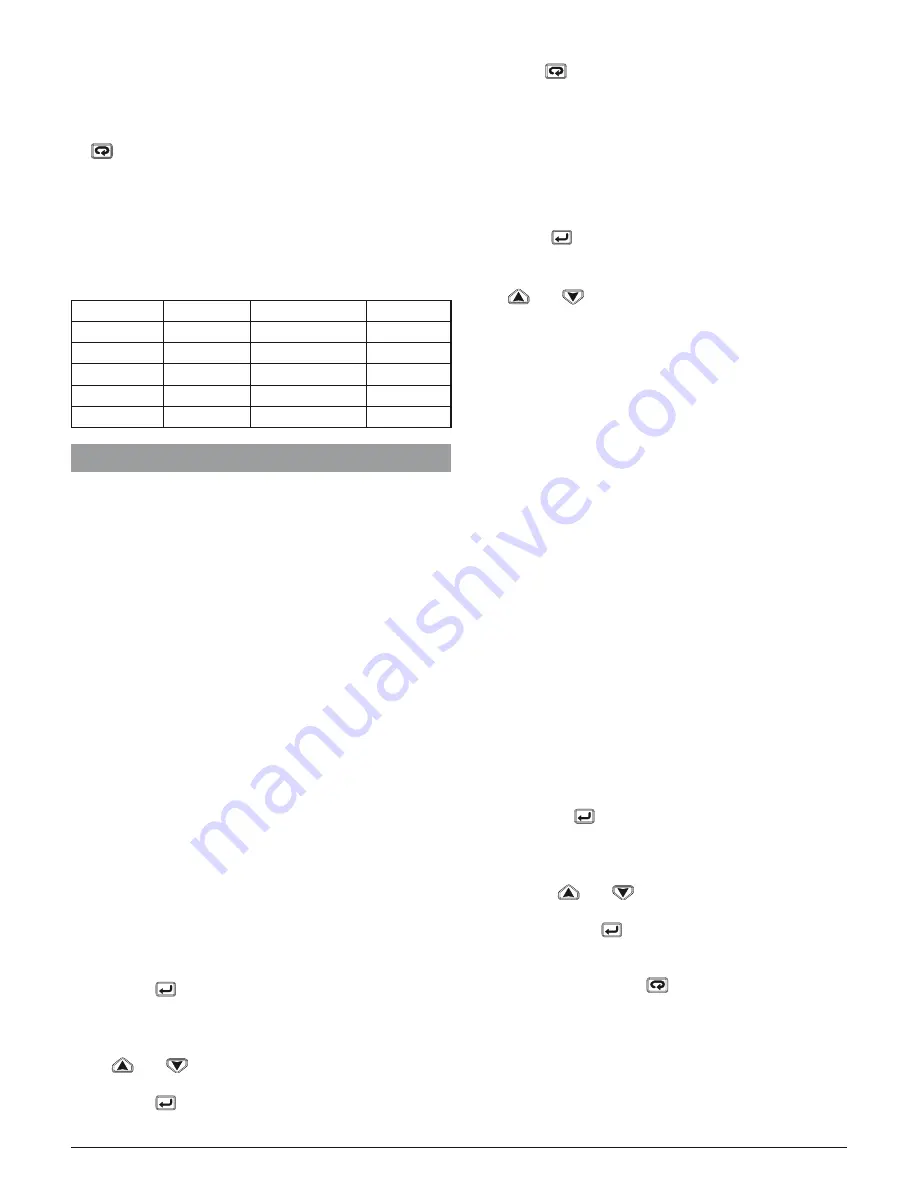

In the previous example, I have set for SP2 a

promotion value equal to A3.

If now I set for SP3 a promotion value equal to

o3

, the

Limited Access list and the operator list becomes.

Parameter

Promotion

Limited Access

Operator

- OPEr -

o 1

OPEr

OPEr

- SP -

o 2

SP

SP

- SP3 -

o 3

SP3

SP3

- A.SP -

A 4

A.SP

- AL1 -

o 5

AL1

AL1

6. OPERATIVE MODES

As we said at paragraph 4.1, when the instrument is

powered, it starts immediately to work according to the

memorized parameter value.

In other words, the instrument has one status only, the “run

time” status.

During “run time” we can force the instrument to operate

in three different modes: Automatic mode, Manual mode or

Stand by mode:

–

In

Automatic mode

the instrument drives automatically

the control output according to the parameter value set

and the set point/measured value.

–

In

Manual mode

the the upper display shows the measured

value while the lower display shows the power output

alternately to the “oPLo” messages and the instrument

allows you to set manually the control output power.

No Automatic action will be made.

–

In

Stand by

mode the instrument operates as an indicator.

It will show on the upper display the measured value and

on the lower display the set point alternately to the “St.bY”

messages and forces the control outputs to zero.

As we have seen, it is always possible to modify the value

assigned to a parameter independently from the operative

modes selected.

6.1 MODIFy A PARAMETER DuRING

“OPERATOR LEVEL”

The instrument is showing the “standard display”.

1. Press the

button.

2. The upper display will show the acronym of the first

parameter promoted to this level while the lower display

will show its value.

3. By

and

button assign to this parameter the

desired value.

4. Press the

button in order to memorize the new value

and go to the next parameter.

5. When you want to come back to the “standard display”

push the

button for more than 5 seconds.

Note:

The parameter modification of the Operator level

is subject to a time out. If no button is pressed for

more than 10 seconds, the instrument goes back to

the “standard display” and the new value of the last

selected parameter will be lost.

6.2 ENTER ThE “LIMITED ACCESS LEVEL”

The instrument is showing the “standard display”.

1. Press the

button for more than 5 seconds;

2. The upper display will show

PASS

while the lower display

will show

0

;

3. By

and

buttons set the value assigned to

[117] PAS2 (Level 2 password).

Notes: 1.

The factory default password for configuration

parameters is equal to 20.

2.

All parameter modification are protected by a

time out. If no button is pressed for more than

10 second the instrument comes automatically

back to the Standard display, the new value of the

last selected parameter is lost and the parameter

modification procedure is closed.

When you desire to remove the time out (e.g.

for the first configuration of an instrument) you

can use a password equal to 1000 plus the

programmed password

(e.g. 1000 + 20 [default] = 1020).

It is always possible to manually End the

parameter configuration procedure (see below).

3.

During parameter modification the instrument

continues to perform the control.

In certain conditions (

e.g. when a parameter

change can produces a heavy bump to the

process)

it is advisable to temporarily stop the

controller from controlling during the programming

procedure (its control output will be Off).

A

password equal to 2000 + the programmed value

(e.g. 2000 + 20 = 2020) will switch the control out

off during configuration. The control will restart

automatically when the para-meter modification

procedure will be manually ended.

4.

Push

button.

5.

The instrument will show on the upper display the

acronym of the first parameter promoted to this

level and on the lower display its value.

6.

By

and

buttons assign to this parameter

the desired value.

7.

Press the

button in order to memorize the

new value and go to the next parameter.

8.

When you want to come back to the “standard

display” push the

button for more than 5 s.

6.3 hOw TO SEE buT NOT MODIFy ThE “LIMITED

ACCESS PARAMETERS”

Sometime it is necessary to give to the operator the possibility

to see the value assigned to the parameter promoted in the

Limited Access level but it is important that all changes are

made by authorized personnel only.