14

AEU-350 / AEU-350S

MAINTENANCE AND STERILIZATION

Failure to adhere to the following instructions or blatant misuse of

the device and/or related components will be considered abuse of the

device and will void the warranty.

Call Aseptico at 1-800-426-5913 with any questions on

sterilization procedures.

Purging Water from System

If the unit will not be used for an extended period or exposed to

freezing temperatures, purge the system of all water. Simply empty

the water bottle and install back into place. Operate the air/water

syringe and handpiece with water coolant switched on until only

air comes through the water lines. Saliva and HVE suction lines and

the waste container should also be empty of all liquid.

Water Lines

Disinfect the water lines weekly. Start by purging water from the

system as described in the section above. Prepare a 1:10 bleach

solution (1 part household bleach to 9 parts water). Run the bleach

solution through all water lines. Allow bleach solution to stand in

lines for 10 minutes. Remove water bottle and discard bleach solu-

tion. Flush water bottle and all lines thoroughly with clean water.

Purge all water from system and leave lines dry until next use.

Waste System and Ejector Valves

After each patient, vacuum .3 liter of clean water through either of

the ejector lines (saliva or HVE) then empty the waste container.

Repeat for the remaining ejector line. Vacuum .3 liter of a 1:10

bleach solution through either of the ejector lines (saliva or HVE)

then empty the waste container. Repeat for the remaining ejector

line. Vacuum .3 liter of clean water through either of the ejector

lines (saliva or HVE) then empty the waste container. Repeat for

the remaining ejector line. Purge the lines of liquid. Rinse the waste

container with clean water. The saliva and HVE ejector valves are

autoclavable using any one of the STERILIZATION METHODS listed

on page 15. The ejector hoses are not autoclavable.

CAUTION

: Use only non-foaming cleansers in the vacuum

lines. Foam can get sucked into the vacuum pump causing

permanent damage and voiding the warranty.

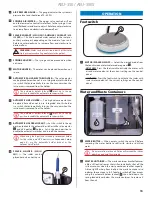

Air Tank Condensation

Drain water condensation from the

air tank daily by pressing up on the

valve

A

on the bottom of the air

tank. Place a towel over the air tank

drain opening

B

to capture the

water as it drains.

Handpieces

Follow the instructions provided with the handpiece for cleaning,

maintenance and sterilization instructions.

Motor & Cord Assembly

!

CAUTION

: The motor is sensitive to shock. Do not drop or

impact the motor against a hard surface.

WARNING

: Do not oil or lubricate the motor.

CAUTION

: Do not allow

oil from the handpiece to

drain into the motor. After

lubricating and before ster-

ilizing the handpiece, stand

it on a paper towel to allow

excess oil to drain out of the

handpiece.

WARNING

: Do not attach

a handpiece to the motor

while the motor is running.

WARNING

: Do not bend

the motor cord sharply.

WARNING

: Do not attempt to disassemble the motor or mo-

tor connector.

WARNING

: Use of sterilization methods or temperatures

other than what are prescribed in STERILIZATION METHODS

on page 15 may damage components or present a risk of

cross-contamination between patients.

CAUTION

: Do not soak or submerge the motor in any liquid.

CAUTION

: Do not use ultrasonic cleaners.

CAUTION

: Do not use cold sterilization or dry heat.

1

Brush off debris from the motor and cord.

2

Thoroughly clean the motor and cord with a moist cloth or

towel to remove any remaining signs of debris. Avoid pulling

the cord away from the motor. Always wipe towards the motor.

A

B