15

AEU-350 / AEU-350S

3

Loosely coil the motor cord when autoclaving. Avoid sharply

bending the cord.

4

Sterilize the motor and cord assembly using any one of the

STERILIZATION METHODS listed below ( page 15).

Syringe Tips

Syringe tips are autoclavable using any one of the STERILIZATION

METHODS listed below (page 15). Wipe off the syringe hand-

piece and hose using a soft cloth dampened with a disinfectant

solution. Do not immerse the syringe handpiece in any liquid nor

spray any liquid directly on the handpiece.

Scaler

(AEU-350S ONLY)

The scaler handpiece cover and scaler tips are autoclavable using

any one of the STERILIZATION METHODS listed below (page 15).

Wipe off the scaler handpiece and hose using a soft cloth damp-

ened with a disinfectant solution. Do not immerse the scaler hand-

piece in any liquid nor spray any liquid directly on the handpiece.

Unit and Footswitch

Clean the unit and footswitch by wiping with a soft cloth moist-

ened with a mild detergent or 1:10 bleach solution (1-part bleach

to 9-parts water). Use of solvents or other solutions may cause

damage and void the warranty.

STERILIZATION METHODS:

Wrapped Sterilization

— Place in an appropriately sized steriliza-

tion pouch and seal.

A Standard autoclaving

(Gravity displacement

method)

Time

: 15 min

Temperature

: 132° C (270° F)

Dry time

: 30 minutes

B Pre-vacuum

(Dynamic air removal method)

Time

: 4 minutes

Temperature

: 132° C (270° F)

Dry time

: 40 minutes

Flash

Sterilization

— For immediate use only.

C Unwrapped standard autoclaving

(Gravity

displacement method)

Time

: 10 minutes

Temperature

: 132° C (270° F)

Dry time

: No dry time is required for flash

sterilization.

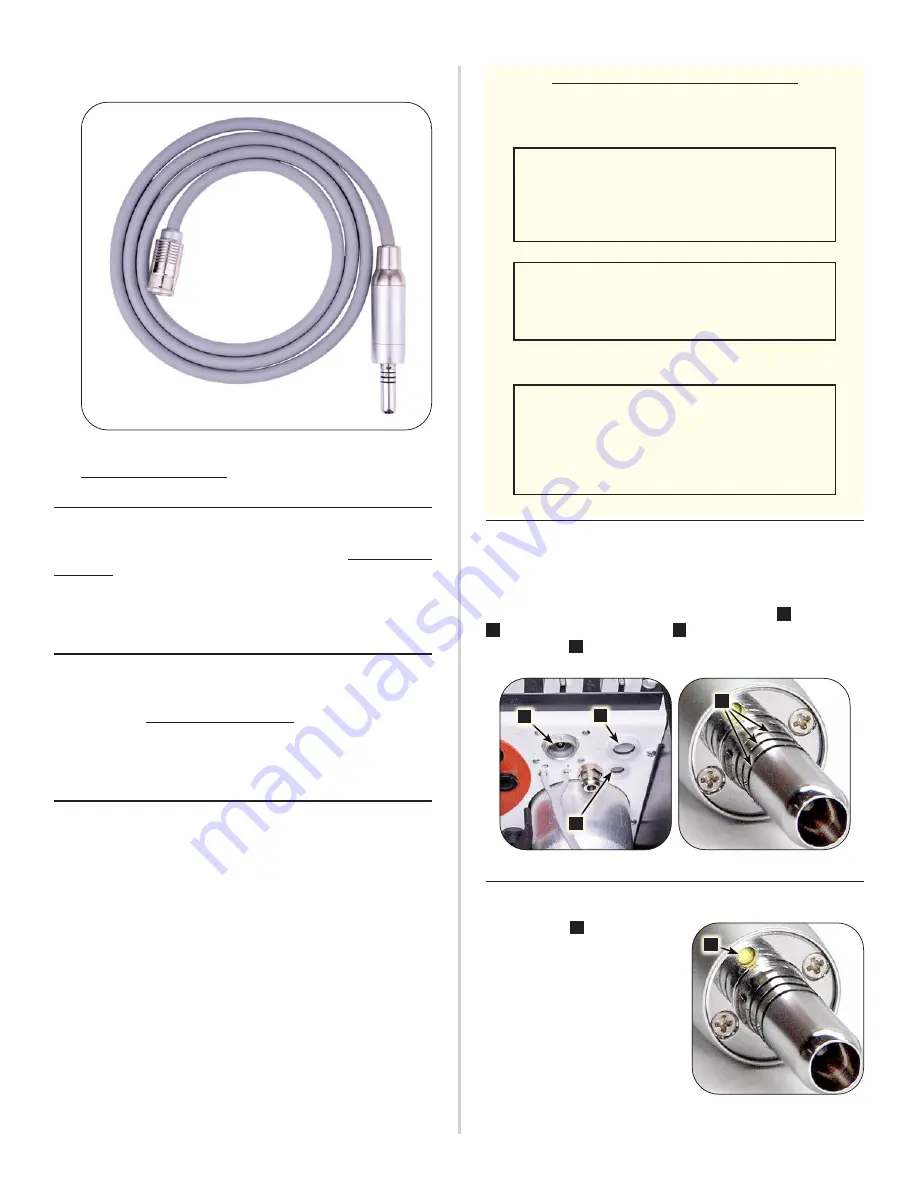

O-Rings

Periodically apply PTFE lubricant to all o-rings to keep the system

operating at peak efficiency. Damaged or worn o-rings can leak

and degrade performance; replace as needed. Bulkhead o-rings

are located in the fittings for the saliva ejector line

A

the HVE line

B

and the electric motor cord

C

(x3) on the bulkhead. Electric

motor o-rings

D

(x3) are located on the motor shaft. Refer to the

Replacement Parts

table on page 18 for o-ring part numbers.

A

B

C

D

Electric Motor LED

The LED lens

A

on the motor is

soft and can easily be damaged

by sharp objects. Dust or debris

may cause a significant decrease in

optical output. Clean the LED using

a lint-free swab and isopropyl

alcohol. Do not use other solvents

as they may damage the LED lens.

A