Page 3

Maintenance and Servicing Instructions

Cleaning and Lubrication

Exposed surfaces of the AA-75CF should be disinfected with a commercial dental disinfectant.

Abrasive cleaning agents have the potential to damage surface finishes and should be avoided. To

minimize the risk of corrosion do not use chlorinated solvents to clean either the inside or the

outside of the compressor valves, the air storage tank or the aftercooler assembly.

Lubrication of AA-75CF compressor components is unnecessary. The compressor uses sealed

bearings and Teflon cylinder technology to eliminate the need for lubrication. The cooling fans

similarly use sealed bearings.

Performance verification

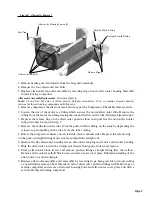

To verify proper compressor function, make sure the tank gauge pressure is at zero, the tank drain

valve is closed and the pressure switch is in the OFF position. Plug the compressor into the power

source. Switch the pressure switch to the AUTO position. The compressor should charge the air

storage tank and the intake and aftercooler fans should run. Confirm that compressor shut off

occurs at approximately 105 psi. Open the tank drain valve. When gauge pressure in the tank drops

below 70 psi, the compressor should restart. Allow the tank to drain until all significant water is

removed. Once the air exiting the tank is dry to the touch, close the tank drain valve. When

compressor cuts off, verify that the fans continue to run for approximately two minutes and that the

tank pressure remains constant near 100 psi. A 5 psi drop can be expected after cut off. Listen for

leaks at pneumatic system connections. If leaks are indicated by pressure loss but are not audible,

check the seals with a soap test. A water-liquid detergent solution should be applied to the circum-

ference of the joint. A leak at a seal will cause the solution to bubble. Tighten the joint, if necessary

reapply Teflon tape, until bubbles no longer appear.

Inspection

The felt media of the air intake filters requires periodic inspection and replacement. Initial inspec-

tion is recommended after 500 hours. Afterwards a service duration should be determined based on

the operating conditions. Excessive felt contamination can reduce compressor output and may affect

service life.

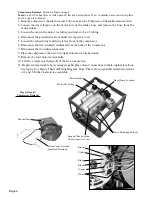

Initial compressor inspection is recommended at 2,000 hours. The wear of the rider ring is an indica-

tion of the general condition of the compressor rings. To inspect the rider rings, remove the

compressor from the case as per Compressor Removal instructions, then disassemble the

compressor cylinder heads. If the rider ring measures 0.055 in. or less, an overhaul should be

performed by installing a Service Kit. See the Compressor Motor Service Kit Installation subsection

of the Disassembly, Repair, Replacement, Reassembly and Check Out Section of this manual for

detailed installation procedures.

Troubleshooting

Symptom

Problem

Action

System non-operational

Main breaker tripped

Reset main breaker

Pressure switch contacts corroded

Replace switch

Compressor motor not running

Main breaker tripped

Reset main breaker

Thermal overload tripped

Allow several minutes to cool and restart

No duplex outlet power

Circuit breaker tripped

Reset duplex breaker

Tank pressure exceeds 110 psi.

Pressure switch settings altered

Readjust according to Pressure Switch

Replacement section note

Compressor attempts to restart under load

Leaking or obstructed check valve

Disassembly and clean or replace.

Misaligned unloader valve

Tighten unloader valve screw and realign.

Extended compressor cycle time

Air demand has been altered

Readjust instruments

Clogged intake filters.

Clean or replace.

Air line leaks.

Tighten couplings, retape.

Water collected in air storage tank.

Blow off tank