Page 4

Motor won’t start with gauge pressure at 0 psi

The thermal protection of the compressor may have been activated. If system fans are still

functioning, allow the unit to cool briefly and restart. If system fans are not running, a high amperage

condition existed resulting in the system circuit breaker being tripped. This condition will result from

a leaking check valve or malfunctioning unloader valve.

Motor experiences labored start with gauge pressure below 70 psi

This condition results from the motor attempting to restart with pressure in the cylinder. This is an

indication of a leaking check valve or malfunctioning unloader valve. Inspect the check valve and the

unloader switch. Service components as required.

Motor starts at an intermediate pressure or Pressure relief valve is activated

Disconnect the unit from the power source. Inspect the pressure switch for excessive wear and

damaged or dirty components. Replace parts as required.

Compressor cycles more frequently than is common

Shut off compressor. Watch the tank pressure gauge. If the tank pressure drops rapidly, check tubing

and fittings for leaks. If tubing and fittings are satisfactorily connected, the check valve should be

inspected for dirt and damage. If after shut off tank pressure is maintained, the tank should be blown

off. Water vapor can condense in the tank and reduce its capacity.

Compressor takes longer to build tank pressure than is common

Check system tubing and fittings for leaks. Inspect compressor air intake filters. Replace filter

cartridge if required.

No power to duplex outlet

Verify system is powered. Reset duplex outlet circuit breaker.

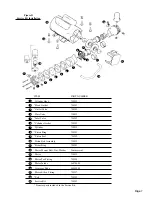

Disassembly, Repair, Replacement, Reassembly and Check Out

The AA-75CF has been designed for minimal required maintenance. Compressor service should be

performed every two thousand hours and component service should be required only when compo-

nent damage occurs or service life is exceeded. Modular construction makes component inspection

and replacement simple. Maintenance can be performed with only the following tools: a 7/16 socket

drive, a set of English Hex wrenches, a 12 in. and an 8 in. crescent wrench, flathead and

#2 Phillips screwdrivers, and a 1/4 inch open face wrench.

For Reassembly, Teflon tape or an equivalent thread sealant should be applied to all pneumatics

fittings and a serviceable thread locking compound should be applied to all fasteners.

To check the success of any repair, perform the procedure detailed in the Performance Verification

section.

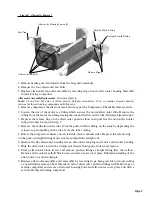

The first step in any major component replacement is the removal of the compressor chassis from

the case bottom.

Compressor Chassis Removal

Tools:

7/16 in. socket wrench and serviceable thread locking compound.

1. Remove case top.

2. Carefully place unit top cover down.

3. Remove the case bumper screws, sealing washers and case bumpers.

Reference Figure B

4. Lift off case bottom. Use a rocking motion to clear ID plate rivets.

5. Replace by reversing steps. Secure case bumper screws using thread locking compound.