3

ADC-02

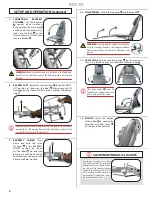

SETUP AND OPERATION

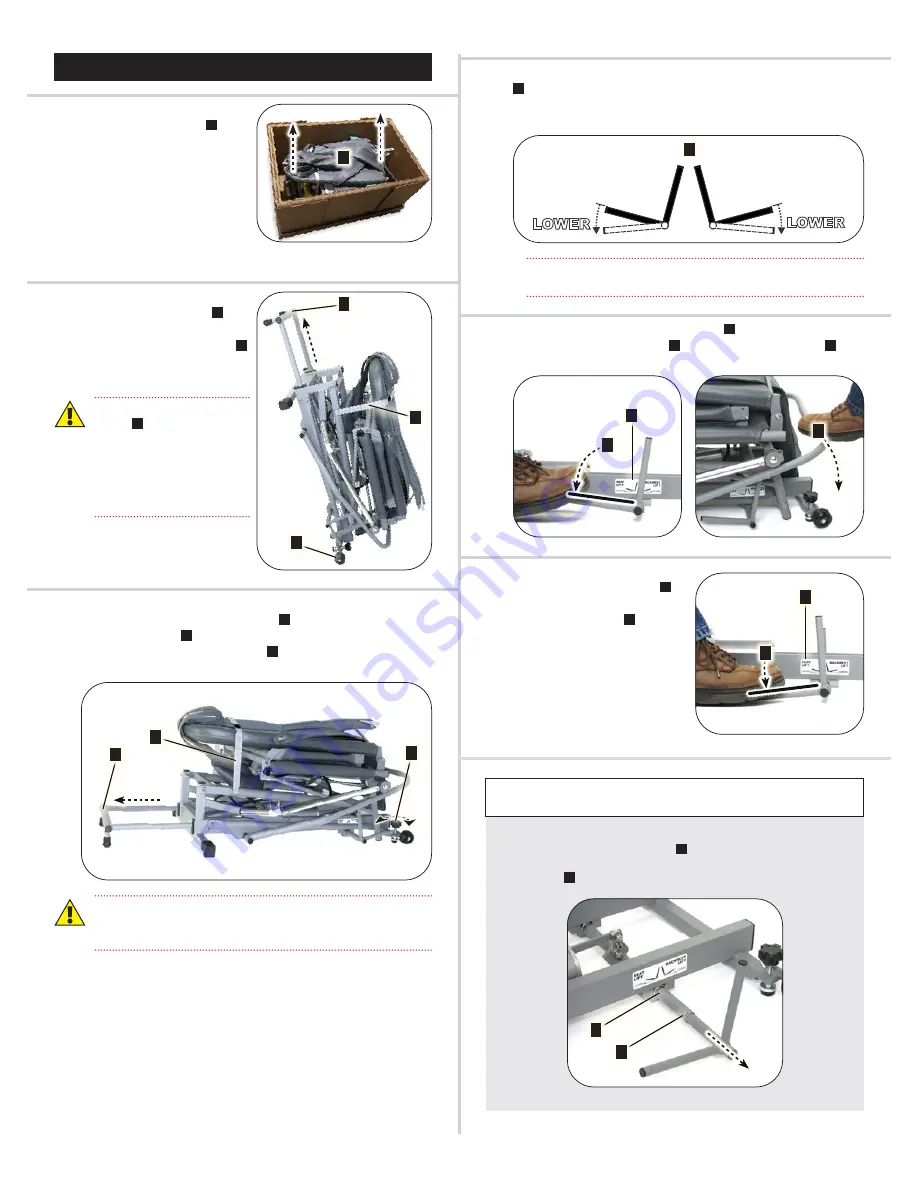

1 UNPACKING:

Using two

people, lift the chair

A

from

the shipping box and set it on

the floor.

2 MOVING INTO POSITION:

Pull out the stabilizer

A

and

use it as a handle to tilt the

chair up onto its wheels

B

,

then roll the chair to where it

will be used.

WARNING:

The backrest

strap

C

must always be

securely fastened when

tilting the chair upright to

prevent injury or damage

caused by the backrest

suddenly opening.

3 CHAIR PREPARATION:

Set the chair down with its feet on the

floor. Make sure that the stabilizer

A

is fully extended. Adjust

the leveling foot

B

as needed to compensate for an uneven

floor. Remove the backrest strap

C

from the chair and save for

reuse.

A

C

B

WARNING:

The stabilizer must be fully extended and the

leveling foot properly adjusted to reduce chair tipping hazard.

The floor under the chair must be hard and level.

4 SELECTOR LEVER LABELS:

Locate the 2 selector lever labels

A

on opposite sides of the chair base. These labels show the

selector lever positions for lifting and lowering the seat and

the backrest.

A

SEAT

LIFT

L O W E R

BACKREST

LIFT

L O W E R

The selector lever can be operated hands-free from either side

of the chair.

5 SEAT LIFT:

Rotate the selector lever

A

to the SEAT LIFT posi‑

tion (as shown on the label

B

) then pump the lift lever

C

with

your foot until the chair reaches the desired height.

A

B

C

6 SEAT LOWER:

Press down and

hold the selector lever

A

in

the SEAT LOWER position (as

shown on the label

B

) to lower

the chair.

The selector levers can be extended outward to make them easier to

The selector levers can be extended outward to make them easier to

reach. Depress the locking button

reach. Depress the locking button

A

on the selector lever tube, then

on the selector lever tube, then

slide the selector lever out until the locking button pops out of the

slide the selector lever out until the locking button pops out of the

second hole

second hole

B

on the tube.

on the tube.

A

B

EXTENDING THE SELECTOR LEVERS

A

A

B

C

A

B