7

ADC-02

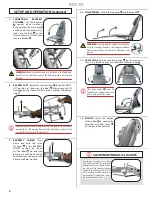

ADDING OIL TO THE HYDRAULIC SYSTEM

With prolonged use, small amounts of oil may leak out of the hy‑

draulic system and need to be replenished. Check the oil level if:

• The hydraulics begin to feel sluggish or jerky and purging air

out of the system (page 5) does not resolve the issue.

• The seat or backrest do not reach their maximum height

when being raised.

1.

Press down and hold the selector lever in the BACKREST

LOWER position (Fig. 9

A

) while simultaneously pushing down

on the backrest (Fig. 9

B

) until it is fully reclined.

Fig. 9

Fig. 9

A

B

2.

Disconnect the backrest latch from the backrest cylinder and

fold the backrest forward, over the seat.

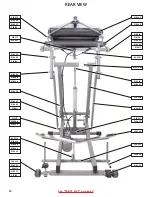

3.

Using a 1/4’’ Allen wrench, remove the oil FILL plug (Fig. 10

A

)

from the pump cylinder.

Do not remove the other two plugs on the pump—doing so

will introduce air into the hydraulic lines.

Fig. 10

Fig. 10

A

4.

Press down and hold the selector lever in the SEAT LOWER

position until the seat is fully lowered. This will cause the

hydraulic oil to rise to its maximum level inside the reservoir.

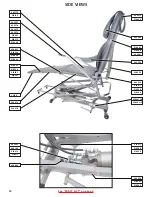

5.

Using a small mirror and a flashlight, look down into the oil fill

port and observe the oil level. The oil (yellow‑green) should

come up to the bottom of the threads (Fig. 11

A

). If not, top off

with a premium quality, medium‑grade hydraulic oil (ISO VG

46, SAE 15), such as Mobil DTE 25.

Fig. 11

Fig. 11

A

7.

Reinstall the oil fill plug while the chair is still collapsed.

Whenever hydraulic oil has been added to the system, the

system should be purged of any air that might have infiltrated

the system (see

Purging Air From from the Hydraulic System

,

page 5). Confirm that the hydraulics work properly before

resuming patient procedures.