5

ADC-02CF

CLEANING AND MAINTENANCE

CLEANING

Clean the upholstery by wiping with a soft cloth moistened with

a mild detergent. Although not recommended, bleach diluted to

<10% with water can be used but must be wiped dry immediately.

The use of solvents or other solutions may cause damage and void

the warranty.

The use of barrier covers will greatly extend the life of the chair

upholstery.

PURGING AIR FROM THE HYDRAULIC SYSTEM

If the hydraulic operation of the ADC‑02CF feels soft or jerky, the

system may need to be purged of air.

With normal use, small amounts of air can enter the hydraulic

system. Air may be in the pump, seat or backrest cylinders. Since

air will always rise to the top of contained hydraulic oil and there

are no bleeder valves, special procedures are required to purge air

from the cylinders:

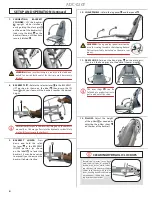

1.

QUICK

PURGE:

Put the selector lever (Fig. 1

A

) in the SEAT

LIFT position and pump the lift lever (Fig. 1

B

) with several

brisk full strokes. This may simply resolve the problem. If the

hydraulic operation is still not satisfactory, proceed to step 2.

A

B

Fig. 1

Fig. 1

2a.

PUMP CYLINDER PURGE:

Put the selector lever (Fig. 2

A

) in

the SEAT LIFT position. Press down on the lift lever (Fig. 2

B

)

and hold it there so you can access the rubber bump stop (Fig. 2

C

). Remove the rubber bump stop by twisting and pulling on it.

A

B

C

Fig. 2

Fig. 2

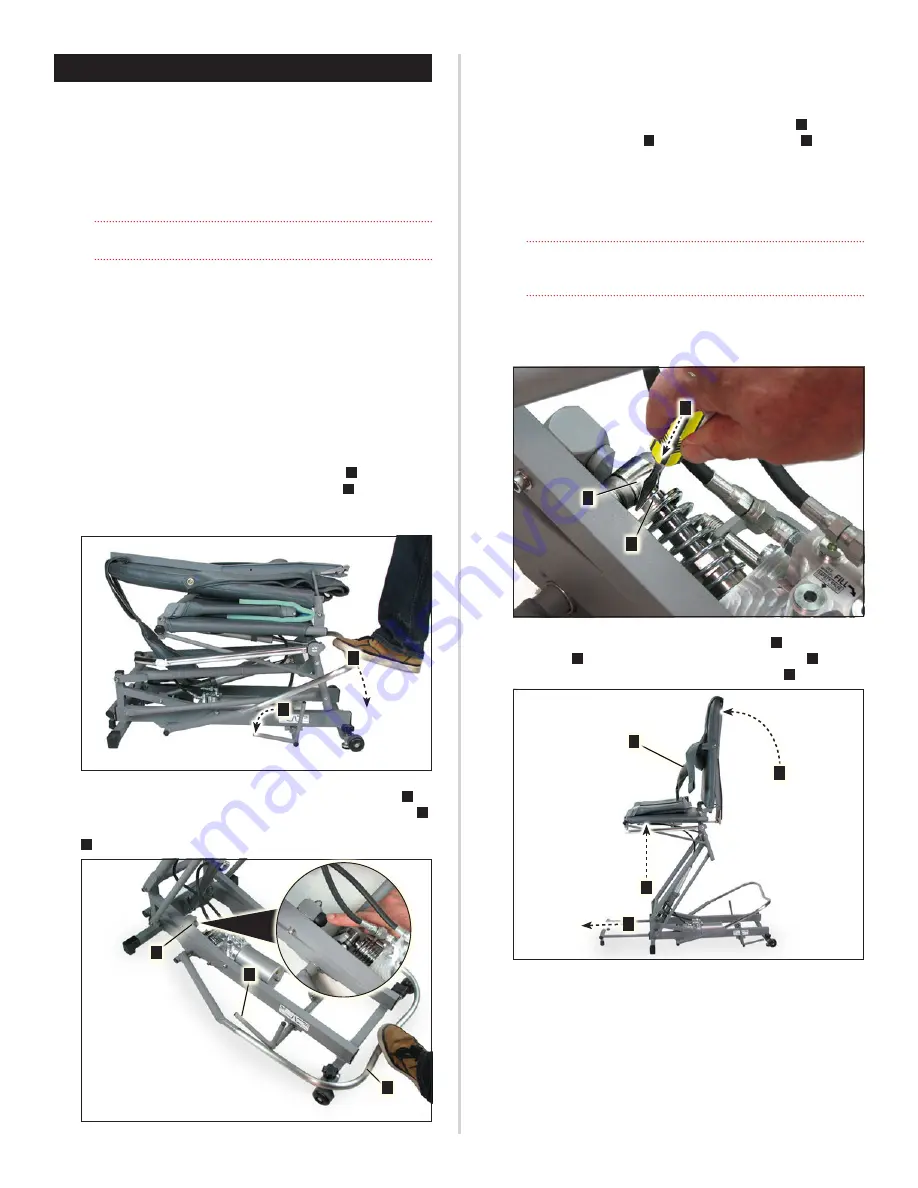

2b.

The object now is to force the pump piston all the way into the

pump cylinder to purge any trapped air. You will need a flat‑

blade screwdriver with shaft diameter of 3/8” or larger. Push

the lift lever all the way down with one hand and with the

other hand, place the tip of the screwdriver (Fig. 3

A

) between

the pump roller (Fig. 3

B

) and pump piston (Fig. 3

C

). As you

allow the lift lever to come up, wedge the screwdriver further

down between the pump roller and pump piston. It may take

a couple of strokes to wedge the screwdriver in far enough

until the lift lever stops where the pump piston has “bottomed

out” and all the air has been purged.

If the seat reaches full height before you are able to push the

pump piston all the way in, you will need to lower the seat part

way to continue.

Complete this operation by reinstalling the rubber bump

stop removed in step 2a. If the hydraulic operation is still not

satisfactory, proceed to step 3a.

Fig. 3

Fig. 3

A

B

C

3a.

SEAT CYLINDER PURGE:

Raise the seat (Fig. 4

A

) and the back‑

rest (Fig. 4

B

) all the way up. Tie the arm slings (Fig. 4

C

) loosely

over the pillow. Fully extend the stabilizer (Fig. 4

D

).

A

B

Fig. 4

Fig. 4

C

D

Summary of Contents for ADC-02CF

Page 14: ...14 ADC 02CF ...

Page 15: ...15 ADC 02CF ...