8

ADC-02CF

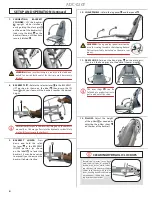

DISASSEMBLY

OVERVIEW

: When disassembling the ADC‑02CF Chair, it is recom‑

mended that its modular components be detached and removed

in the following order:

1

Backrest Assembly

2

Seat Assembly

3

Hydraulic Assembly (*)

4

Base Assembly

(*) The individual components of the hydraulic assembly are not

customer‑serviceable and shouldn’t be disassembled in the field.

Return to Aseptico if repairs are required.

1

2

3

4

1

BACKREST ASSEMBLY

Disengage the backrest

latch [PN 462239] (Fig.

12

A

) from the backrest

cylinder.

Use a 3/16” Allen wrench

and 1/2” combination

wrench to remove the bolts

[2x PN 510815], washers [4x

PN 510845], spacer wash‑

ers, [A/R PN 510297] and

nuts [2x PN 510126] (Fig. 13

A

) that attach the backrest

assembly to the seat frame.

Note the quantities and po‑

sitions of the “A/R” (as required) spacer washers between the com‑

ponent frames. These washers should be used as spacers during re‑

assembly to ensure a snug fit. Detach the backrest assembly and

set on workbench.

Use a Phillips screwdriver

to remove the pillow strap

mounting screws [2x PN

510239] (Fig. 14

A

) that at‑

tach the pillow strap [PN

462313] to the rear of the

backrest. Remove strap

and pillow [PN 462304].

Use a 5/32” Allen wrench

to remove the screws

[PN 510841], washers [PN

510500] and bushings [PN

462301] (Fig. 14

B

) that attach the arm slings [PN 462289] to the

sides of the backrest.

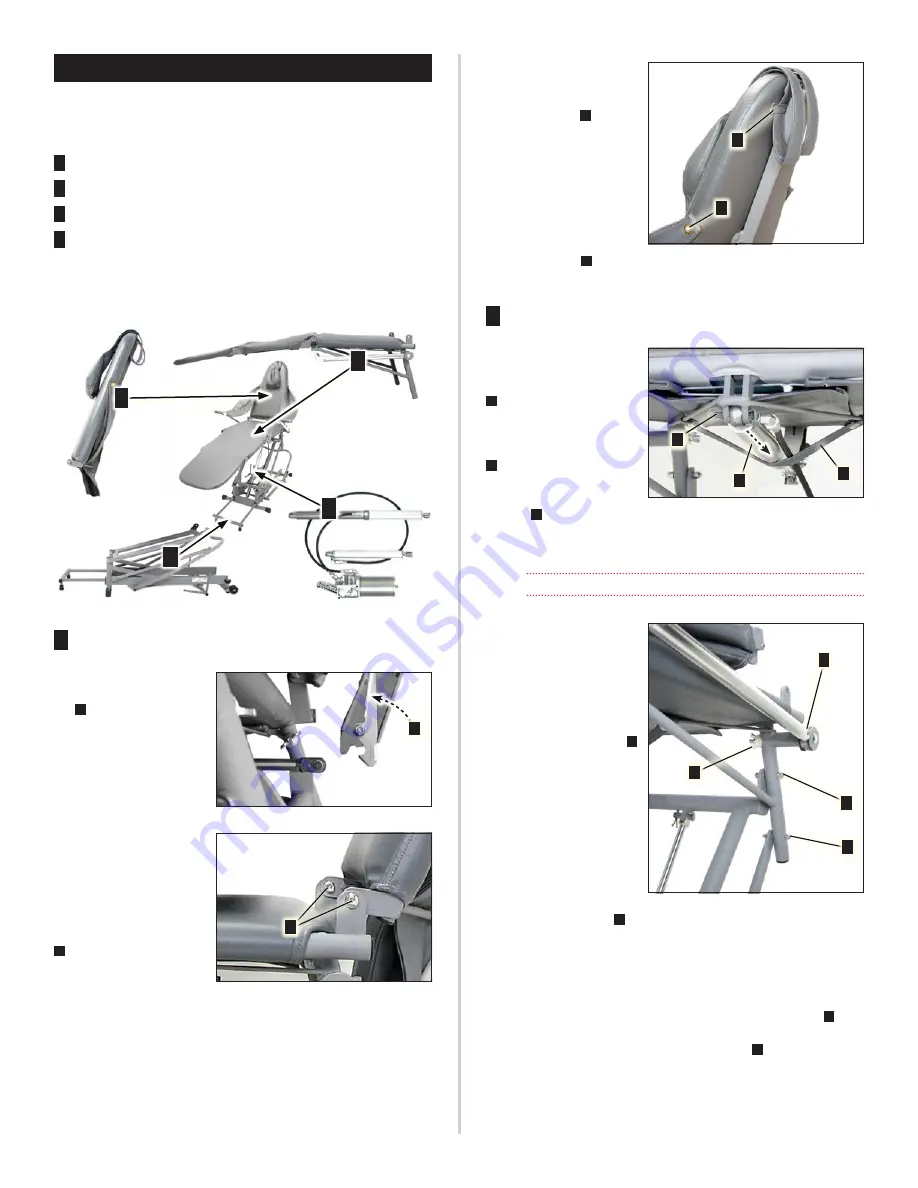

2

SEAT ASSEMBLY

Remove the clevis pin

[PN 510917] and cotter

ring [PN 510927] (Fig. 15

A

) that attach the back‑

rest cylinder to the under‑

side of the seat assembly.

Push the cylinder (Fig. 15

B

) with attached hydrau‑

lic hose backward over the

support strap [PN 462291]

(Fig. 15

C

) and out from under the seat. Rest the cylinder on the

floor until the complete hydraulic system can be detached as a

unit.

Do not disconnect the hydraulic hose from the cylinder.

Fold the foot and leg pan‑

els closed onto the seat

panel. Use a 3/16” Allen

wrench and 7/16” combina‑

tion wrench to remove the

bolts [2x PN 510842], wash‑

ers [6x PN 510500] and nuts

[2x PN 510296] (Fig. 16

A

)

that attach the seat frame

to the base struts [2x PN

462191]. Note: One wash‑

er is installed between the

seat frame and each strut.

Use a 1/4” Allen wrench and

1/2” combination wrench

to remove the bolts [2x PN

510809], spacer washers [8x

(A/R) PN 510845] and nuts

[2x PN 510126] (Fig. 16

B

) that attach the seat frame to the main le‑

ver [PN 330614]. Note the quantities and positions of the A/R spacer

washers between the component frames; these washers should be

used as spacers during reassembly to ensure a snug fit. Detach the

seat assembly and set on workbench. Remove the wing nuts [2x PN

510311], bolts [2x PN 510810], rubber washers [4x PN 710138], coved

washers [2x PN 510822] and washers [2x PN 510845] (Fig. 16

C

) that

attach the arm posts to the seat frame. Use an 1/8’’ Allen wrench

to remove the small screws [6x 510312] (Fig. 16

D

) that connect the

arm post components together.

A

Fig. 12

Fig. 12

Fig. 13

Fig. 13

A

Fig. 14

Fig. 14

A

B

Fig. 15

Fig. 15

B

A

C

Fig. 16

Fig. 16

A

B

C

D

Summary of Contents for ADC-02CF

Page 14: ...14 ADC 02CF ...

Page 15: ...15 ADC 02CF ...