9.

Problem:

Unit will not start

Unit starts but blows fuse

No water coming out

Insufficient vacuum

Insufficient handpiece operation

Compressor makes a chugging

sound and does not start up

properly

Correction:

Check system’s power connection.

Turn Run Mode Switch to “Continuous” or “Foot Switch” Mode and begin operation.

Check that voltage selector module is set for source voltage.

Check fuse. If blown, replace with 6.3A/125V medium time delay fuse for 120V

operation, or a 4A/250V slo-blo fuse for 230V operation.

Check that voltage selector module is set for source voltage.

Check vacuum waste container. If full, immediately empty to continue operation.

Check vacuum hose assembly for blockage.

Check that fuse is correct for source voltage.

Check water supply tank for water level and verify that cap is tight.

Depress foot switch for 5+ sec. to pressurize supply tank.

Ensure the handpiece air control valve is not opened all the way.

Check vacuum waste container. If full, immediately empty to continue operation.

Check vacuum hose assembly for blockage.

Check that waste container lid is properly seated and tightly secured.

Check that handpiece ON/OFF toggle is “ON”.

Check that handpiece coolant ON/OFF toggle is “ON”.

Check that air control valve is turned up adequately

Check that handpiece tubing is untangled and not crimped.

Check handpiece connection for missing gasket.

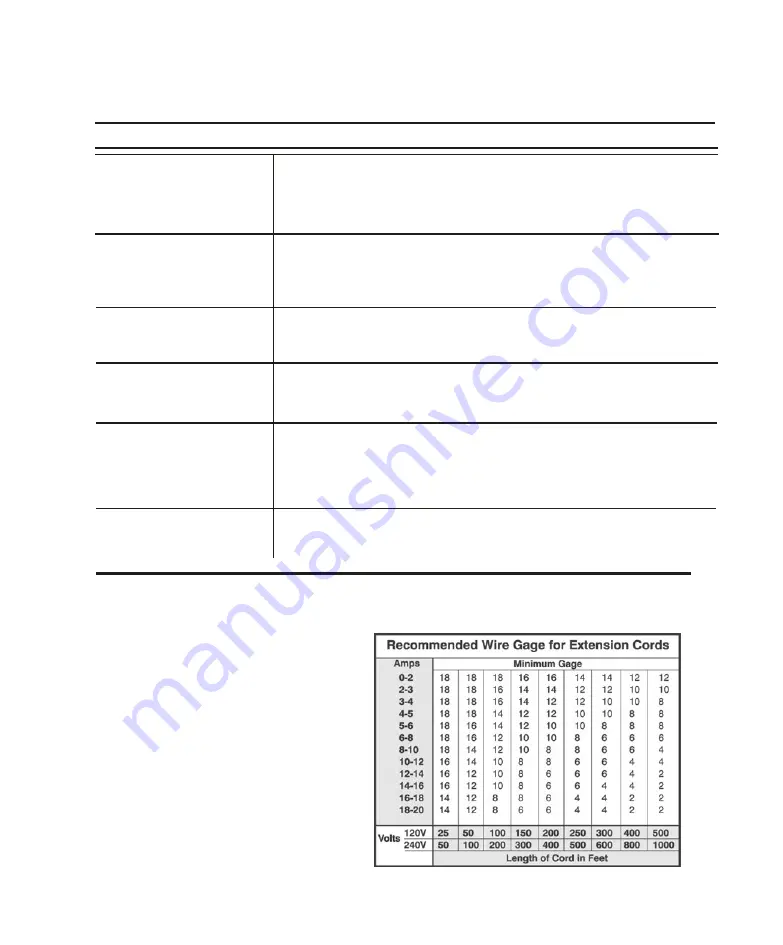

Check for sufficient power source and avoid long light-grade extension cords

(Refer to Figure 8 Extension Cord Recommendations - below)

TROUBLESHOOTING:

EXTENSION CORD RECOMMENDATIONS:

Use only a 3-wire extension cord that has

a 3-blade grounding plug. Connect

extension cord plug to a matching 3-slot

receptacle. Ensure that the extension

cord is in good condition and that its gage

wire is the correct size wire to carry the

current this product will draw. An

undersized cord is a potential fire hazard

and will cause a drop in line voltage,

resulting in loss of power and causing the

product to overheat. Figure 9 indicates

the correct size cord for the length

required and the ampere rating listed on

the product nameplate.

If in doubt, use

the next heavier gage cord. The

smaller the gage number, the heavier

the wire gage.

FIG. 9