9

AEU-1000-70V / AEU-1000

Customizing Presets

The Preset segment of the screen will flash if you have made any

adjustments to the settings of the current preset:

To

clear

any adjustments made to the current preset, simply press

and

immediately release

the flashing Preset segment of the

screen.

To

save

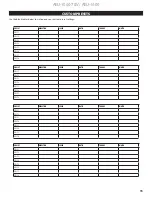

the adjustments that you have made (to customize the

current preset), press and hold the flashing Preset segment of

the screen until you hear a beep. You may write down the settings

for your custom presets in the blank tables on page 15.

Factory Restore

To

restore

all presets to their factory settings:

1 .

Press the Torque segment of the home screen.

2 .

Press and hold the “CAL” button that appears between the

and

buttons until you hear a beep.

3 .

Press and hold the flashing “RECALL” button that appears in the

Preset segment of the screen until you hear another beep.

The factory settings have been restored for all presets (all user

customized presets have been erased).

4 .

To

cancel

the factory restore procedure, press anywhere on

the right side of the screen before completing step 3 above.

Calibrating Handpieces

Because the mechanical condition of motors and handpieces

changes over time, it is recommended that you calibrate hand-

pieces every time you power up the unit and

especially

when you

change handpiece models:

1 .

Confirm that the correct handpiece ratio and handpiece

model are selected in the settings.

NOTE:

For AHP-64 hand-

pieces, use the AHP-85MB-X handpiece model setting and the

1:1 ratio setting.

2 .

Insert a drill, bur or file into the handpiece.

3 .

Position the handpiece in the cradle so that the drill/bur/file

can rotate freely without touching anything.

4 .

Press the Torque segment of the home screen.

5 .

Press the “CAL” button that appears between the

and

buttons to start the calibration process. The CAL button will

flash and the motor will run through several speed changes,

then stop.

6 .

If calibration is successful, the CAL button will stop flashing

when the motor stops.

If the CAL button continues to flash after the motor stops,

calibration has failed. Try calibrating again. Repeated

failures can indicate a dirty, damaged or defective

handpiece and/or a motor in need of repair or replacement.

7 .

Press anywhere on the right side of the screen to return to the

home screen.

OPERATION

This section explains how to operate the unit using either the AE-70V2

or AE-7PM foot controller.

AE-70V2 Foot Controller

The AE-70V2 foot controller provides multiple-function control of

the system.

VARIABLE SPEED PEDAL —

This pedal activates the motor and

irrigation pump simultaneously. The motor speed varies (up to

the current Speed setting) in proportion to how far down you

press the pedal. The irrigation pump activates at the current

water setting, regardless of how far down the pedal is pressed.

PRESET —

Press repeatedly to step through each of the

presets sequentially. This provides the same function

as pressing the Preset segment (page 8) on the

touch screen.

MOTOR DIRECTION —

Press to alternate between

forward and reverse. This provides the same function

as pressing the Motor Direction icon (page 8) on

the touch screen.

HANDLE —

Use to manually position the foot

controller. Install the handle by inserting the

handle prongs into the holes on the rear of the

foot controller.

TORQUE STEP-INCREASE —

For 20:1 handpieces,

press to increase the torque setting in 2 Ncm steps for a

maximum of 5 consecutive steps (or until the maximum

torque setting is reached). On the sixth press (or the press after

the maximum torque setting is reached), the torque setting

will return to the original, lowest setting.

WATER ON-OFF / STEP-INCREASE —

Press to switch

the irrigation pump on-off. When the pump is switched

off, the Water segment (page 8) of the screen will

display “— —” instead of 0%. Press

and hold

this button to

step through the water settings in +10% increments; the steps

occur at 1-second intervals with a beep sounding to signal

each step.