Page 7

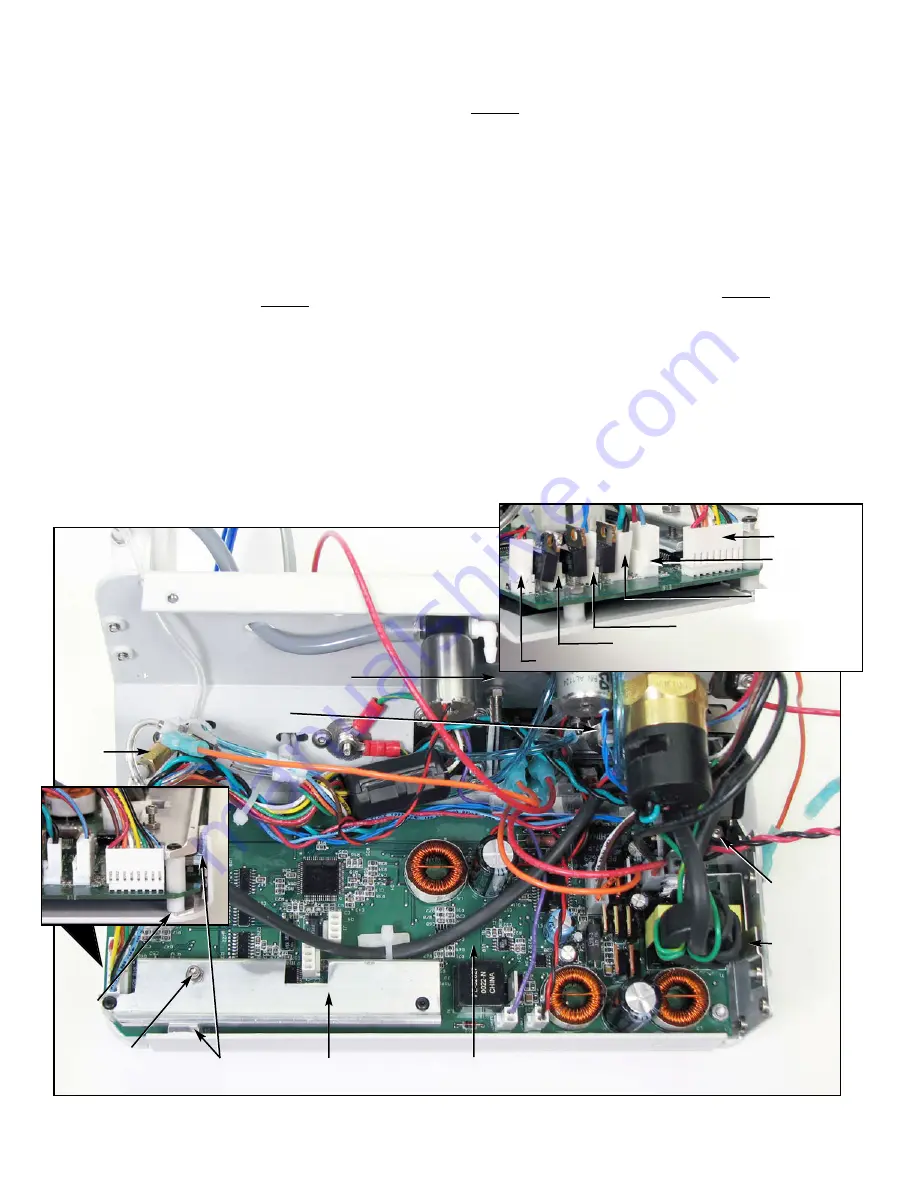

POWER BOARD - Fig. 4

Remove the pump cover as previously described under

“Power Supply” disassembly procedure. Remove the two

screws that hold the power cord receptacle and pull the

receptacle forward. Use a 3/32-inch Allen wrench to remove

the screw that attaches the two insulators and the diode

heatsink bracket. Remove bracket. Use a 1/16-inch Allen

wrench to remove the mounting screw for the trans heatsink

bracket, then remove bracket. Remove the heatsink clamp

mounting screw and standoff with a 1/16-inch Allen wrench.

Remove heatsink clamp. Remove the two mounting screws

for the heatsink clamping bracket with a 1/16-inch Allen

wrench, then remove bracket. (NOTE: It isn’t necessary to

remove the hold-down screw and locking nut mounted on the

top of the heatsink clamping bracket.) Remove the upper

heatsink bracket located on top of the power board IC chip.

Remove the two nylon standoffs from the power board.

Remove all wire and cable connectors to the power board.

Remove the remaining two nuts and washers with a 1/4-inch

socket. Lift the board off the studs to expose the ribbon cable

on the back side of the power board. Remove the thermo pad

and lower heat sink bracket from the bottom side of the

power board. Remove the ribbon cable at the power board.

NOTE: The cable connector has been sealed at the factory

with RTV - remove the RTV from cable.

To replace power board with a new board, set the new board

90° to mounting position in the unit and insert the ribbon

cable into the socket. The socket requires that both sides of

the connector lock be pushed closed at the same time. Ensure

that the cable and connector are properly aligned and seated

to each other. It is recommended to seal the ribbon cable to

the connector with RTV and allow to dry, to prevent

condensation shorts on the connector. NOTE: If RTV is not

available, use a piece of electrical tape to seal the connector

and prevent movement of the cable when reassembling.

Realign the power board to its proper mounting position and

install back in the chassis.

Reassemble power board in the reverse order. Apply thermo

compound to all heatsinks and heatsink brackets per

instructions provided on Assembly Drawing 420541, sheets 13

thru 19. Ensure there is no continuity between the upper and

lower heatsinks.

Figure 4

Needle

Valve

Power

Board

Check

Valve

Filter

Holder

Heatsink

Clamp

Heatsink

Diode

Bracket

Heatsink

Clamping Bracket

Hold-Down

Screw &

Locking Nut

Upper Heatsink

Bracket

Lower

Heatsink

Bracket

3-Way Solenoid Conn.

Pump Conn.

2-Way Solenoid Conn.

Pressure Switch

Conn.

Foot Pedal

Conn.

Motor Conn.