8.

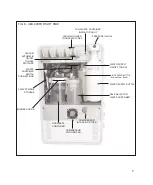

OPERATION FUNCTIONS:

1. Power Switch

:

Controls power on/off to console. When

the AEU-425FO is turned on, the Electric

Control Console will light.

2. Handpiece Ratio Selector

:

Calibrates the Handpiece Ratio Indicator to

read accurately for four different handpiece

ratios. Push the Handpiece Ratio Selector

until the Handpiece Ratio Indicator

matches the handpiece ratio you are using.

Different handpiece ratios are required to

obtain different speed ranges for dental

procedures. Ratio settings are held in

memory even after unit is turned off.

3. Speed (RPM) Selector

:

Controls speed of motor and handpiece.

Push the up arrow to increase speed and

the down arrow to decrease speed. The

Speed (RPM) Indicator shows actual

RPM. For complete display accuracy, the

Handpiece Ratio Indicator must exactly

match the ratio of the handpiece being

used. Speed settings are held in memory

even after unit is turned off.

4. Forward/Reverse Selector:

Determines the rotation of the motor and

handpiece. A red L.E.D. light and audible

beeper indicate the reverse rotation.

5. Handpiece Water Coolant:

Switches the water coolant to the

handpiece on and off, and adjusts the

flow. When switched to the on position,

coolant water will flow when the

handpiece is in operation. Rotate the

Handpiece Coolant Flow Adjustment Knob

Handpiece

Speed

Ratio

Range (RPM)

1:5 Increaser

25,000 - 150,000

1:1

4,000 - 30,000

4:1 Reduction

1,000 - 7,500

16:1 Reduction

300 - 1,800

clockwise to decrease water flow and

counterclockwise to increase water flow.

6. Handpiece Coolant Air

- Switches the air

coolant to the handpiece on and off. When

switched to the on position, coolant air will

mix with the water flow to create a spray

when the handpiece is in operation.

7. Three-Way Air/Water Syringe

:

Pressing the left button dispenses water.

Pressing the right button dispenses air.

Pressing both buttons simultaneously

dispenses an air/water mist.

8. Optional Ultrasonic Scaler

:

See accompanying documents.

The Ultrasonic Scaler has adjustable

ultrasonic levels and a water coolant

system.

The scaler includes 3 instrument tips: The

#37 instrument is specially developed for

subgingival scaling, furcations,

supragingival fine scaling and spot

removal. The #38 tip is used for lingual and

buccal subgingival scaling and furcations.

The #39 tip is used for universal lingual

and buccal supragingival scaling.

The scaler is controlled by the Scaler

Ultrasonic Setting Adjustment Knob. Turn

clockwise to set the ultrasonics to max.

Turn counterclockwise to set the

ultrasonics to min.

9. Coolant for Optional Ultrasonic Scaler:

The coolant level is controlled by the Scaler

Coolant Flow Adjustment Knob. Turn

counterclockwise to increase coolant flow.

Verify that scaler coolant

flow of no less than

20ml/min is available at

the tip.

See Accompanying Scaler Documents