1.

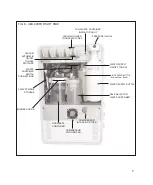

Turn the power switch on the front of the

console to the 'ON' position. The Electric

Control Console will light and the unit will

pressurize.

NOTE:

Whenever the pump turns on, the

HVE vacuum will also come on.

2a. Using the Motor:

Flip the Scaler/Motor Toggle Switch to the

right (Motor) side.

2b.

Attach a sterile handpiece to the motor

and set the Ratio Selector to match the

gear ratio of the handpiece being used

(i.e. 1:5 for a 1:5 increaser handpiece, or

4:1 for a 4:1 reduction handpiece).

2c.

Adjust the up/down arrows on the RPM

display to the desired operating speed on

the RPM readout.

NOTE:

The RPM display indicates true

bur speed when the Ratio Selector is in

the appropriate position. Make sure the

Ratio Selector matches the handpiece

ratio for display accuracy.

2d. Motor Coolant/Irrigation:

Turn the Handpiece Coolant Switch on.

Adjust the Handpiece Coolant Flow Knob

to the desired setting.

2e. Motor Coolant Air/Irrigation:

Turn the Handpiece Coolant Air Switch on

to create spray. Adjust the Handpiece

Coolant Water Flow Knob to the desired

spray setting.

3a. Using the Optional Ultrasonic Scaler:

See accompanying documents.

Flip the Scaler/Motor Toggle Switch to the

left (Scaler) side. Rinse the water line before

attaching tip by pressing the foot switch and

allowing the water to flow for 30 seconds.

3b.

Screw on a sterile Instrument Tip to the

Scaler Handpiece and tighten it firmly.

Turn carefully backwards approx. 1mm.

This will put the tip in a neutral position so

it can move freely.

3c.

Adjust the Scaler Coolant Flow Control

Knob to the desired setting. The coolant

should create a mist around the Scaler tip.

3d.

Adjust the Scaler Ultrasonic Setting Knob

to the desired setting.

4.

Use the 3-Way Air/Water Syringe as

necessary for irrigation or drying. A plastic

dental barrier sheath made for the 3-way

syringe must be used on syringes that

have not been autoclaved.

5.

Adjust the vacuum pressure by moving the

valves on both the HVE and saliva

ejectors.

6.

Press the foot control to activate Motor or

Optional Scaler and begin operation.

7.

Empty the Vacuum Waste Tank when it is

75% full. If the red ‘Full waste container

indicator light’ turns on, the vacuum system

is full. When this occurs, shut down vacuum

system, and empty the waste tank.

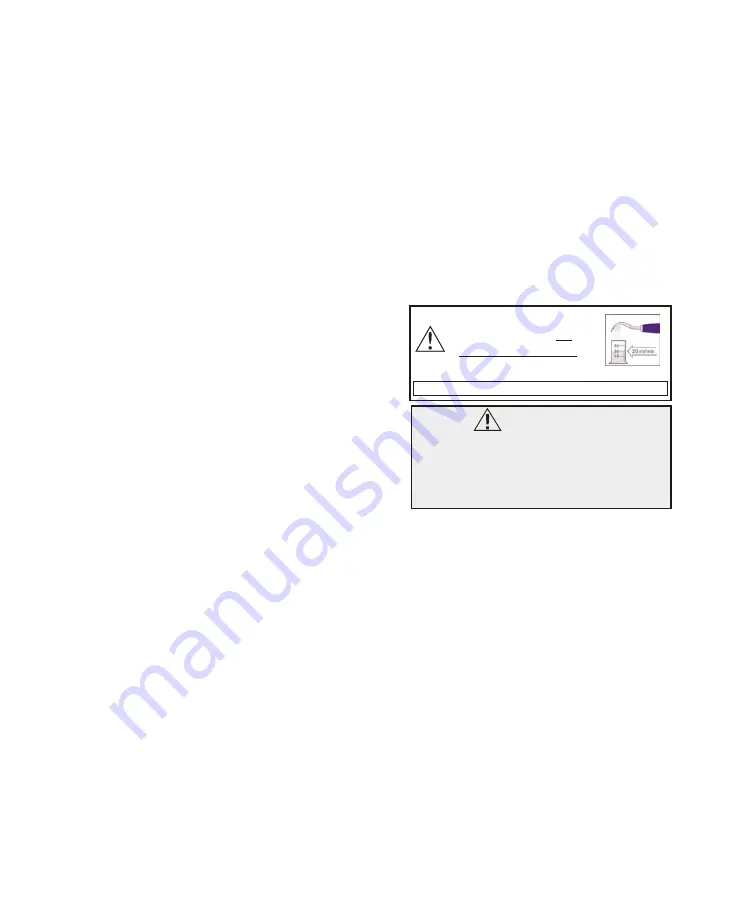

WARNING:

Ensure proper coolant flow before using

Scaler on a patient. Heat emitted by the

Scaler may damage teeth if coolant

water is not atomized at the Scaler tip.

OPERATION:

After the unit has been set up and you have made yourself familiar with the operation functions,

you are ready for operation as follows:

11.

Verify that scaler

coolant flow of no

less than 20ml/min is

available at the tip.

SEE ACCOMPANyING SCALER DOCUMENTS