4

1.

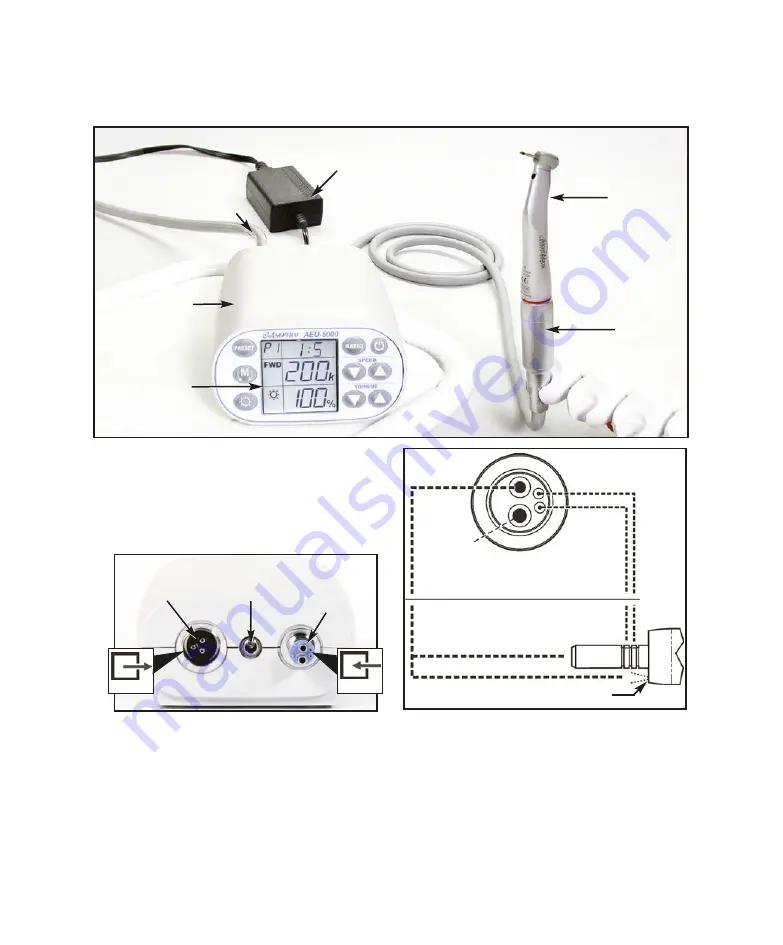

Unpack the Console and accessories (see

Figure 1).

2.

Attach the 4-hole handpiece tubing connector

from the office dental system to the

receptacle on the back of the AEU-5000

console (refer to

INPUT

symbol in Figure 2).

3.

Note the alignment of the four air/water ports

on the AEU-5000 receptacle with the four

holes on the handpiece tubing connector.

IMPORTANT:

Ensure that all tubing

supplying the unit is properly connected and

that the air and water are delivered to the

console as shown in Figure 3

Fig. 2 - Console Back

MOTOR/CORD

RECEPTACLE

48VDC

POWER INLET

4-HOLE

HANDPIECE

TUBING

RECEPTACLE

NOTE:

A portion of the drive air input is used to cool

the motor and handpiece. This air vents around the

LED and through the E-coupling to the handpiece.

IMPORTANT:

Refer to the handpiece manual for

recommended pressure for chip irrigation air and water,

typically in the range of 10-30 PSI (0.68-2.06 bar). It is

recommended to turn off chip air and water when using

handpieces that do not support irrigation.

SETTING UP THE UNIT:

Fig. 1 - System Components

CONTROL

CONSOLE

LCD

DISPLAY

4-HOLE HANDPIECE

TUBING FROM OFFICE

DENTAL SYSTEM

MOTOR

w/CORD

48 VDC EXTERNAL POWER SUPPLY

(100-240 VAC, 50-60HZ, POWER SOURCE )

HANDPIECE

(Sold Separately)

Fig. 3

CONSOLE AIR/WATER INPUT

MOTOR AIR/WATER OUTPUT

(EXHAUST)

DRIVE AIR

CHIP AIR

CHIP WATER

(LED)

MOTOR

HANDPIECE COOLING AIR

HANDP'C COOLING AIR VENT

INPUT

OUTPUT