19.

Because of its simple design, the

Transport III System requires very little

maintenance. Any maintenance that is

needed can be performed in minutes.

PURGING THE SYSTEM:

If the unit will not be used for an extended

period of time, or if the unit might be

subjected to freezing conditions, the user

should purge the system of all water.

Simply empty the contents of the water

bottle and install it back into its cap, then

operate the air/water syringe, scaler, and

handpiece with water coolant ‘ON’ until

only air comes through the water lines.

Pack the unit and store as normal.

HANDPIECES:

Thorough cleaning and lubrication of E-

type handpieces after each use and before

sterilization is very important to ensure

proper operation and service life of the

handpiece. Follow the instructions

provided with the handpiece for complete

maintenance instructions.

When sterilizing

IMPORTANT!

Protect

motor from excess oil

draining from handpieces.

After lubricating and

before autoclaving, stand

handpiece on its base, on

a paper towel, and allow

excess oil to drain (see

Fig. 39).

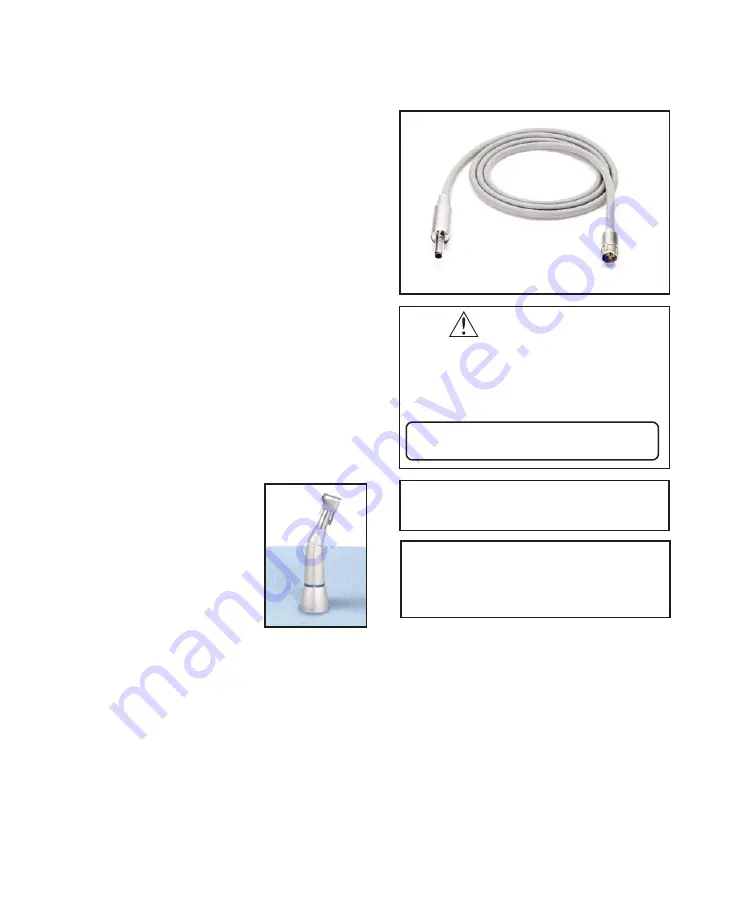

ELECTRIC MOTOR & CORD ASSEMBLY:

The entire Electric Motor and Cord

Assembly is fully autoclavable (Fig. 40).

Steam autoclave motor/cord assembly at

132° C (270° F) for ten minutes. Loosely

coil the motor cord when autoclaving.

Avoid sharply bending the cord when

autoclaving. Alternatively, wipe down the

motor cord with disinfecting solution, and/or

sleeve the cord between each patient.

ELECTRIC MOTOR O-RINGS:

Replace electric motor O-rings when worn

STERILIZATION AND MAINTENANCE:

or damaged (see Fig. 41, page 20). Gently

peel old O-rings out of grooves and

replace with new rings (PN 520069).

Occasionally apply non-toxic lubricant

(preferably containing PTFE) to O-rings to

maintain flexibility.

LARGE O-RINGS

(On Air/Electric Module

and High/Low Vacuum Lines)

:

Keep all O-rings lubricated with PTFE

lubricant. Periodically inspect rings for

damage or excessive wear -- damaged or

worn O-rings will create vacuum leaks,

degrading system performance.

CAUTION FOR ALL STERILIZATION:

• Do not exceed 135° C or 275° F

• Do not submerge in any solutions

• Do not use ultrasonic cleaners

• Do not attempt to disassemble the motor or motor

connector.

• Do not oil or lubricate the motor.

• Do not attach a handpiece to the motor while the

motor is running.

• Do not bend motor cord sharply.

WARNING

CAUTION:

The Electric Motor is sensitive to shock. Do not

drop or impact motor against a hard surface.

Fig. 39

The entire motor & cord

assembly is steam

autoclavable.

Fig. 40 -

MOTOR & CORD STERILIZATION

Failure to comply with any of the above instructions

may void your warranty.