Page 46

Because of its simple design, the Aseptico AEU-525CF

Transport III System requires very little maintenance. Any

maintenance that is needed can be performed in minutes.

PURGING THE SYSTEM:

If the unit will not be used for an extended period of time, or

if the unit might be subjected to freezing conditions, the user

should purge the system of all water. Simply empty the

contents of the water bottle and install it back into its cap,

then operate the air/water syringe, scaler, and handpiece

with water coolant ‘ON’ until only air comes through the

water lines. Pack the unit and store as normal.

HANDPIECES:

Thorough cleaning and lubrication of E-type handpieces

after each use and before sterilization is very important to

ensure proper operation and service life of

the handpiece. Follow the instructions

provided with the handpiece for complete

maintenance instructions. When sterilizing

IMPORTANT!

Protect motor from excess

oil draining from handpieces. After

lubricating and before autoclaving, stand

handpiece on its base, on a paper towel,

and allow excess oil to drain (see Fig. 122).

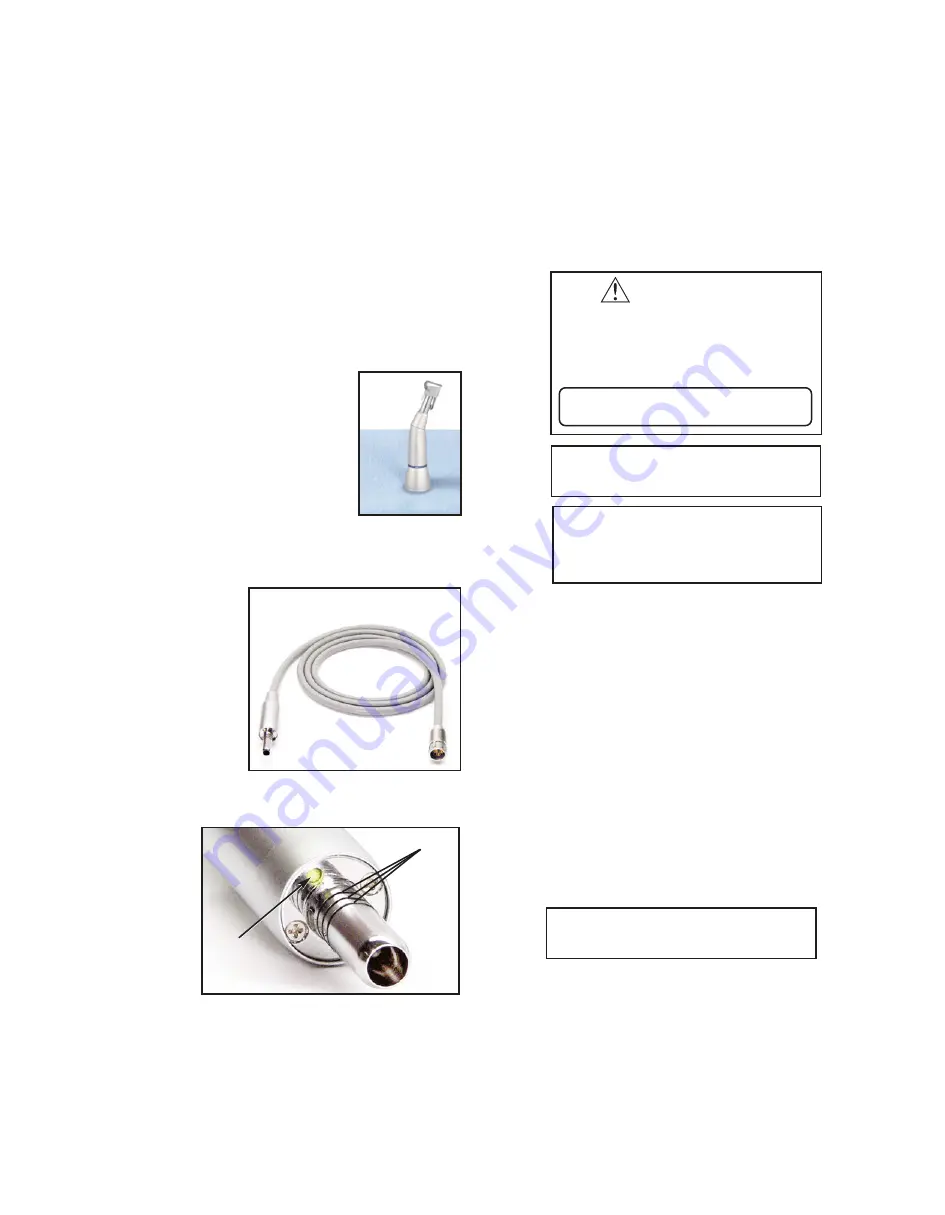

ELECTRIC MOTOR & CORD ASSEMBLY:

The entire Electric Motor and Cord Assembly is fully

autoclavable (Fig. 123). Steam autoclave motor/cord

assembly at 132° C (270°

F) for ten minutes. Loosely

coil the motor cord when

autoclaving. Avoid sharply

bending the cord when

autoclaving. Alternatively,

wipe down the motor cord

with disinfecting solution,

and/or sleeve the cord

between each patient.

ELECTRIC MOTOR O-RINGS:

Replace electric motor O-rings when worn or damaged (see

Fig. 124). Gently

peel old O-rings

out of grooves and

replace with new

rings (PN 520069).

Occasionally apply

n o n - t o x i c

( p r e f e r a b l y

containing PTFE)

lubricant to O-rings

to

maintain

flexibility.

LARGE O-RINGS

(On Air/Electric Module and High/Low

Vacuum Lines):

Keep all O-rings lubricated with PTFE lubricant. Periodically

inspect rings for damage or excessive wear -- damaged or

worn O-rings will create vacuum leaks, degrading system

performance.

STERILIZATION AND MAINTENANCE:

MOTOR LED LENS CLEANING:

The lens of the LED light on the motor (see Fig. 124) is soft

and can be damaged. It should not be exposed to dust and

debris. Excessive dust and debris may cause a drastic

decrease in optical output. In the event that the light

requires cleaning, first try a gentle swabbing, using a lint-

free swab. If needed, use a lint-free swab and isopropyl

alcohol to gently remove dirt from the lens. Do not use other

solvents as they may adversely react with the LED

assembly.

GENERAL CLEANING:

The external surfaces of the chassis should be cleaned

using a soft cloth moistened with a mild detergent solution.

Any external surfaces of the unit that are contacted during

use should be wiped down with a soft cloth moistened with

a disinfectant at the beginning of each day and between

each patient use.

WATER LINES:

Disinfect the water lines weekly. Prepare a 1:10 bleach

solution (1 part household bleach to 9 parts water). Remove

water bottle and discard residual water. Replace empty

water bottle and air purge all waterlines. Fill water bottle

with bleach solution. Run bleach solution through all lines.

Allow bleach solution to stand in lines for 10 minutes.

Remove water bottle and discard bleach. Flush water bottle

and all lines thoroughly with clean water. Air purge and

leave lines dry until next clinical use.

VACUUM SYSTEM:

The HVE and low-volume saliva ejector valves are fully

autoclavable. Remove the valves from their hoses before

autoclaving. The vacuum hoses should not be autoclaved.

Clean hoses with a disinfectant solution.

CAUTION

: Use

only NON-foaming cleansers in the vaccum lines.

Fig. 122

CAUTION FOR ALL STERILIZATION:

• Do not exceed 135° C or 275° F

• Do not submerge in any solutions

• Do not use ultrasonic cleaners

• Do not attempt to disassemble the motor or motor

connector.

• Do not oil or lubricate the motor.

• Do not attach a handpiece to the motor while the

motor is running.

• Do not bend motor cord sharply.

WARNING

CAUTION:

The Electric Motor is sensitive to shock. Do not

drop or impact motor against a hard surface

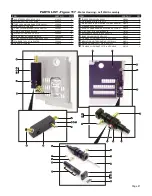

Fig. 124

O-RINGS

(3)

LED

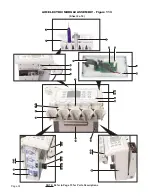

THE ENTIRE MOTOR &

CORD ASSEMBLY IS

STEAM AUTOCLAVABLE.

Fig. 123

- MOTOR & CORD

STERILIZATION

CAUTION:

Do not run saline solutions through the water

system -- saline will rust the water filters.

Failure to comply with any of the above instructions

may void your warranty