Page 47

AIR BOTTLE FILTER:

Routinely check the air bottle filter once a day for

condensation. To drain condensa-tion, place a towel or

container below the filter and use pliers to carefully loosen

the black knob on the bottom of the filter. IMPORTANT: To

open the drain, turn the black knob clockwise (follow arrow

on “DRAIN “ label); to close drain, turn the knob

counterclockwise. Do not overtighten.

WASTE SYSTEM CLEANING:

Empty and clean the waste system whenever the level alarm

occurs. Also empty and clean it routinely once a day or

before the unit is to be shipped or stored. Follow these steps:

1) Empty all waste from the waste container, including any solids

trapped in the HVE strainer in the waste container lid.

2) Prepare approximately 2/3 liter of 10% bleach/water solution in a

separate container. Submerge the end of the high-vacuum ejector

(HVE) into this bleach solution and pull no more than 1/3 liter of the

solution through the line into the waste container. Repeat this

process for the saliva ejector (low vacuum) line. IMPORTANT: The

solution will enter the waste container at a very high rate -- Care

must be taken not to overfill the container’s waste compartments.

3) Discard bleach solution. All components of the waste container,

including the lid assembly and waste container strainer, can be

safely rinsed with 10% bleach solution. (NOTE: Take care to ensure

that water is kept off the level-sensor electrical connector on the

case.) Rinse and dry tanks and the lid. If unit is to be shipped or

stored, hang vacuum lines vertically to allow any residual water to

drain before packing.

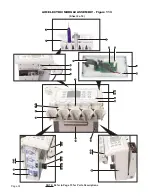

3-WAY AIR/WATER SYRINGE:

Depress the right button for air operation, and the left button

for water operation. Depressing both buttons will create a

mist. The syringe features quick-change autoclavable tips: To

remove a tip, press on the locking collar surrounding the tip

socket and pull the used tip straight out of the socket (Fig.

125). To insert a new tip, press locking collar and push tip into

socket as far as it will go. Release ring and gently tug on tip

before using to ensure that tip is securely locked into socket.

Syringe Tip Sterilization:

1)

Remove contaminated syringe tip.

2)

Remove all visible signs of contamination before

autoclaving.

3)

Autoclave tip at 132° C (270° F) for ten minutes.

4)

Sterilize between each patient use.

NOTE:

Since only the tips can be autoclaved, it is

recommended that the air/water syringe be bagged with a

disposable, single-use plastic sleeve between each patient

use.

ULTRASONIC SCALER:

The scaler handpiece cover and scaler tips are fully

autoclavable. Disinfect and clean the cover and tips before

autoclaving. Autoclave at a maximum temperature of 135° C

(275° F) for 10 minutes or 120° C (248° F) for 20 minutes.

Wipe off the scaler handpiece and it’s silicone hose with a

soft cloth. Use a 45% isopropal and detergent solution.

DO

NOT IMMERSE

the handpiece in any fluid or spray any fluid

directly on the handpiece.

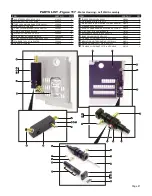

MOTOR/CORD RECEPTACLE O-RINGS:

The O-rings (PN 520081) for the three water/air ports in the

motor/cord receptacle should be replaced if damaged or

worn. Use the provided O-ring installer pin and sleeve to

replace the O-rings:

1.

Remove old O-ring from water or air port fitting.

2.

Slide new O-ring over pointed end of installer pin, onto

the pin’s shank (see Figure 126).

3.

Insert pointed end of installer pin into open end of

installer sleeve until O-ring stops against end of tool.

4.

Position concave end of installer pin against end of

water/air port fitting (see Figure 127).

5.

Push installer sleeve inward, until new O-ring seats into

groove on fitting (see Figure 128).

AIR FILTER ASSEMBLY:

The foam filter on the Air Filter Assembly should be cleaned

regularly if the AEU-525CF is used in a dusty environment.

Gently pull the foam sheet off the white mounting studs on

the Assembly frame and clean with soap and water or

compressed air. If washed, allow filter to dry before

operating unit.

FIG. 125

DEPRESS

LOCKING COLLAR

O-RING

INSTALLER

SLEEVE

FIG. 128

INSTALLER

PIN

O-RING

INSTALLER

PIN

FIG. 126

O-RING

FIG. 127

WATER/AIR

FITTING