Page 3

Water Lines

Disinfect the water lines weekly. Prepare a 1:10 bleach

solution (1 part household bleach to 9 parts water).

Remove water supply bottle and discard residual water.

Replace the empty water supply bottle and air purge all

waterlines. Fill water supply bottle with bleach solution.

Run bleach solution through all lines. Allow bleach solution

to stand in lines for 10 minutes. Remove water supply

bottle and discard bleach. Flush water supply bottle and all

lines thoroughly with clean water. Air purge and leave lines

dry until next clinical use.

REFER TO STERILIZATION AND MAINTENANCE SECTION ON PAGE

46 FOR MORE CLEANING INSTRUCTIONS.

Adhesives

Refer to included Schematic Drawing Set, PN 420991, for

proper identification and application of all adhesives.

ESD PRECAUTIONS

The following electrostatic controls must be used when

working on this unit:

ESD Training and Standards:

Employees handling electronic sub-assemblies and ESD

sensitive components are expected to be trained. Training

should be based on IPC-A-610 or equivalent ESD standard

ANSI/ESD-S-20-20 – Protection of Electrical and Electronic

Parts, Assemblies and Equipment.

ESD Static Controlled Area:

Areas that are designated for handling and working on

electronic sub-assemblies or their components should be

marked off with signs indicating the area where ESD controls

are to be enforced. These areas are to be kept clear from

persons that are not trained to prevent ESD damage from

occurring.

ESD Environment:

The work area is to be free of all static generating materials,

such as plastic containers, water bottles, plastic bags, plastic

objects, such as plastic pens, heat guns (unless made for the

ESD environment).

ESD Jackets:

Clothing should be non-static generating (cotton).

Static generating clothing (e.g. wool, acrylic, nylon) must be

covered with an ESD jacket that is buttoned closed.

Optional gloves:

Nitrile gloves may be used to cover the hands when working,

but are not required.

Seating:

ESD Chairs should be used in place of static generating

chairs (e.g. modern office seating use static generating

materials).

Storage and packaging:

All circuit boards and components are to be stored on or in

static dissipative or static shielding material, throughout

shipping and storage.

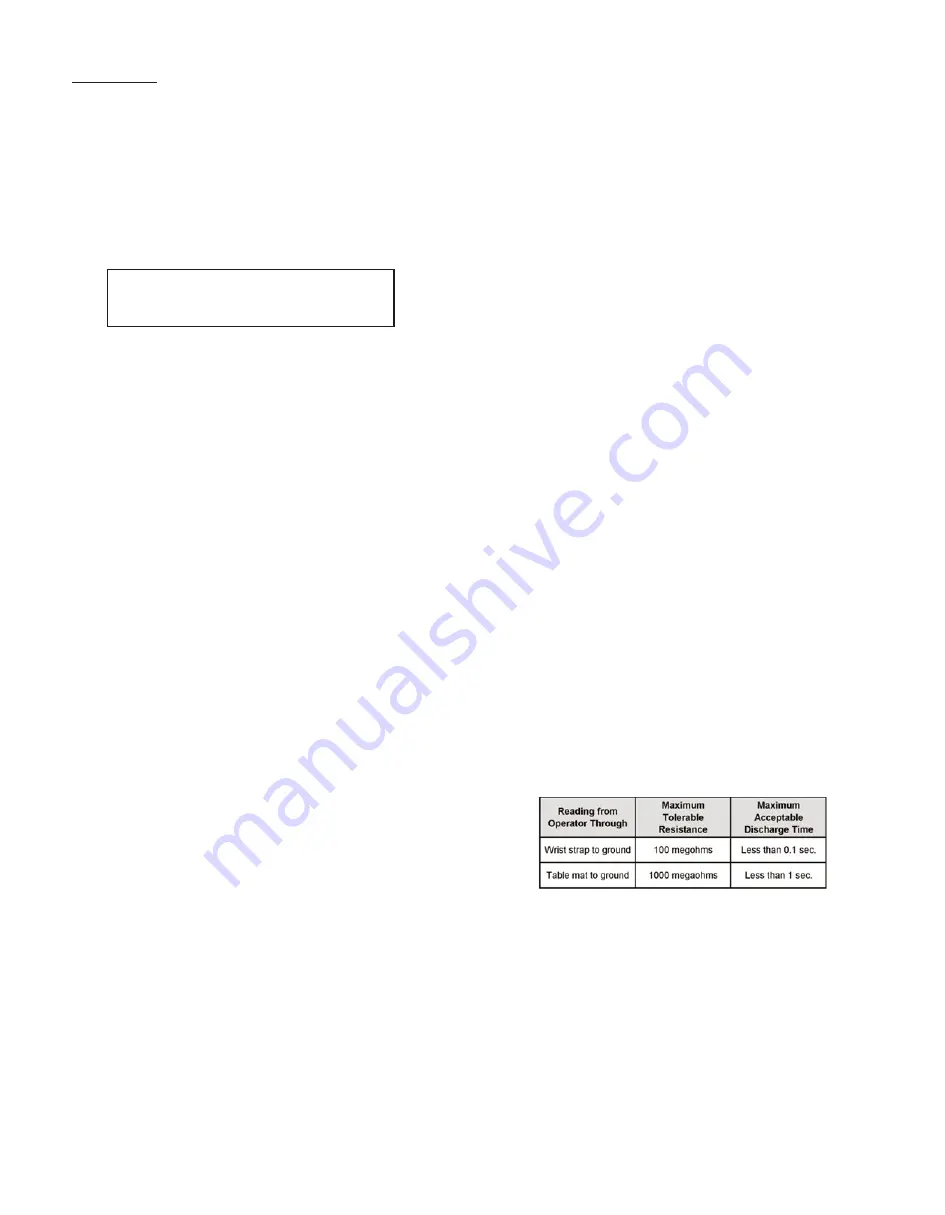

ESD Wrist Strap and Mat Routine Checks:

The wrist strap should be checked daily using an ESD wrist

strap testing station. See chart below.

ESD mats should be checked at least quarterly.

CAUTION:

Do not run saline solutions through the water

system -- saline will rust the water filters.