Page 51

preset number stops flashing. Now press the footpedal

to turn on the motor and LED and then release it and

verify that the LED remains on for 20 +/-5 seconds.

9.

Place the motor into a calibrated ATU-0037

tachometer. Confirm that the torque is set to 100%.

Set the speed to 40.0KRPM. Press the footpedal to

turn on the motor and record the speed which the

tachometer shows and verify that it is 40.0KRPM +/-

2.0KRPM. Values outside this range are non-

conforming.

10.

Attach an Anthogyr 8:1 (actually 7.2:1) handpiece to

the motor and set the controls to 8:1 ratio, 500RPM,

100% torque and ENDO mode. Attach the handpiece

to the bit on the dynamometer assembly (copper

cylinder) and press the footpedal. While the motor is

running, decrease the Torque% setting until the motor

stops and goes into ENDO mode. Record the Torque

% setting where this happens. It should be less that

50% and greater than 5%. If not, remove the

handpiece and lubricate it with Aseptispray and repeat.

If it still fails, mark it as nonconforming.

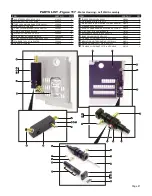

11a

. Remove the handpiece. Depress the foot pedal

with the Handpiece Water and Handpiece Air toggle

valves off and check that no cooling air or water is

coming from the two holes between the 0-rings on the

motor E-head. You will feel motor cooling air at the

front of the E-head however.

11b.

Turn the Handpiece Air toggle valve on and adjust

the Handpiece Air needle valve on the Delivery Module.

Depress the footpedal and verify that air is coming from

the motor E-head hole between the two o-rings farthest

from the motor body on the E-head.

11c.

Partially fill the Delivery Module water bottle and

insert an internal irrigation type handpiece such as the

AHP-72MB onto the motor. Turn the Handpiece Air

toggle valve off and the Handpiece Water toggle valve

on and adjust the Handpiece Water needle valve on the

Delivery Module. Depress the footpedal and verify that

water is coming from the handpiece. Turn on the

Handpiece Air and verify that a fine mist is coming from

the handpiece.

11d.

Operate the handpiece motor with the Handpiece

Air toggle on and then turn the toggle off while still

operating the motor. Release the foot pedal and place

the hand motor firmly in its holder and wait 5 seconds.

Press the footpedal. If the motor comes on, the

designed leak isn’t present or of adequate magnitude.

11e.

Turn off the AEU-525 and trip the HVE and bottle

pressurization toggles to remove all compressed air

from the system. Close the toggles. Fill the ATU-0088

bottle to the line on the side and mount on the AEU-

525. Turn on the AEU-525 and observe the final

pressure of the ATU-0088 gauge. It should be between

25 and 35 PSI and should be reached within 10

seconds of turn on. Repeat steps 4 more times. If

pressure is wrong or it takes too long to pressurize then

the module needs to be reworked.

12.

Simultaneously hold the Preset and Ratio buttons

until the display resets and factory defaults are set.

F. Performance Test (Syringe):

1.

Fill the water bottle and turn on the compressor to fill

the air reservoir. Press the syringe air button (the right

one) and check that the pressure gauge doesn’t go

below 20 PSI. If it does, change the screwdriver adjust

for the syringe air.

2.

Release the syringe air button and allow the

compressor to refill the reservoir. Press the syringe

water button (left one) and verify that water comes out

the syringe.

3.

Press both buttons and verify that a mist is created.

4.

Use ATU-0090 and plug the syringe tip into the

syringe. Press the syringe air button and observe the

MAXIMUM pressure on the gauge. It must be between

48.0 and 55.5 PSI

G. Performance Test (Scaler):

1.

Remove scaler from its holder, install a tip, turn the

scaler intensity to “10”, turn the Scaler Water control

counterclockwise as far as it will go, turn the Scaler

Water toggle valve on and press the foot pedal and

observe that the scaler produces water from the tip, that

the scaler lights come on, and that when the scaler tip is

placed against a thin metal surface, there is high pitched

noise produced.

2.

Turn the Scaler Intensity control from “10” to “100”

and back and verify that the control adjusts the intensity

of the scaler vibrations.

3.

With the Scaler Intensity control set to “10”, adjust the

Scaler water control clockwise and counterclockwise to

verify that it controls the amount of water coming from

the scaler tip.

4.

Press the foot pedal several times to verify that the

scaler goes on and off with no more than a ½ second

delay. Remove the scaler tip

H. Performance Test (Waste Tank)

1.

Remove the Waste Tank lid from the tank and with

the floats at the bottom place the .82“ spacer over the

sensor wells and then press each float upward as far as

possible. There must be no alarms. Remove the .82”

spacer and lift each float about .250” and there must be

flashing from the red LED on the lid and beeping from

the main case.

2.

Turn on the HVE so that the compressor is on

continuously and place a .0625 spacer above the first

float and raise the float as high as possible. The

compressor must stop.

3.

Repeat for other float.

I. HiPot and Ground Bond Tests:

1.

On the AC/DC Withstand Voltage Tester, press MENU

-> MENU -> SYSTEM and change the “PLC REMOTE”

setting to “OFF”.

2. Ground Bond Test

- Earth Ground at Power Inlet to

accessible earthed metal.

Test parameters:

Current limit 25 Amps, Dwell time 2

seconds, Resistance limit 0.1 Ohms.