13

located above the preset button will illumi-

nate, indicating which preset is activated.

Note:

If a preset is activated and its set-

tings are changed in any way, the preset’s

LED will turn off, signifying that the unit has

switched back to the Manual Mode of oper-

ation.

13.Editing Presets

- All six preset memory

buttons can be edited by the user with new

settings, at any time. These new settings

will overwrite the existing settings, includ-

ing factory defaults. In addition, the

“Labels” (names) for each of the presets

can be edited by the user for easy identifi-

cation of the new preset.

Note:

At any time during the following edit-

ing process, the CANCEL button can be

pressed to return to the operation screen.

Step 1:

Adjust each of the Ratio, Speed, Torque,

Flow, Rotation Direction, and Pump On/Off

settings to the desired values via the

control panel buttons (refer to descriptions

on pages 6 - 8).

Step 2:

Press and hold any of the Preset buttons

1 through 6, to save the new, modified

settings into that particular button.

Step 3:

A display prompt then asks the user:

Preset - (X)

Save Settings? YES/NO

Press the ‘Yes’ Button on the

Display to confirm the save.

The prompt then displays the

message:

Preset - (X)

Setting Saved

Step 4:

A display prompt then asks the user:

(Label Name)

Edit Label? YES/NO

Press the ‘Yes’ Button on the

Display to confirm that the Label

needs to be edited and the new

Preset renamed.

An editing “Help” message displays briefly:

Edit Label With Arrows

Step 5:

Use the Left or Right

arrow buttons to move

the display cursor

left/right under the top

line of text characters.

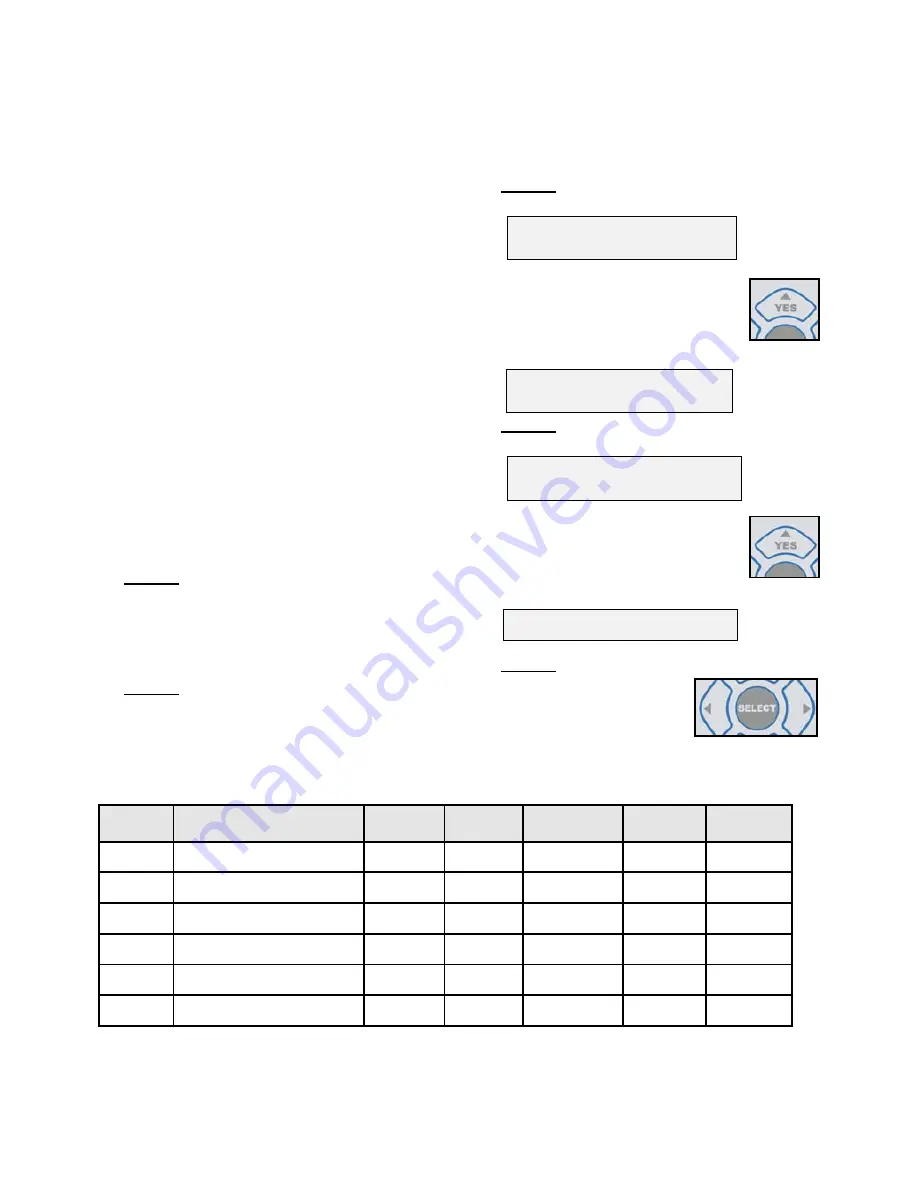

FIG 9 - Factory Presets

PRESET

NAME (Label)

RATIO

SPEED

DIRECTION TORQUE

FLOW

1

Site Preparation

1:2

60,000

FWD

2.75 N•cm

100%

2

Pilot Drill

20:1

1,200

FWD

MAX

80%

3

Finish Drill / Reamer

20:1

800

FWD

MAX

80%

4

Tap Forward

20:1

15

FWD

25 N•cm

30%

5

Tap Reverse

20:1

35

REV

35 N•cm

Off

6

Install Implant / Abutment

20:1

15

FWD

32 N•cm

Off