9

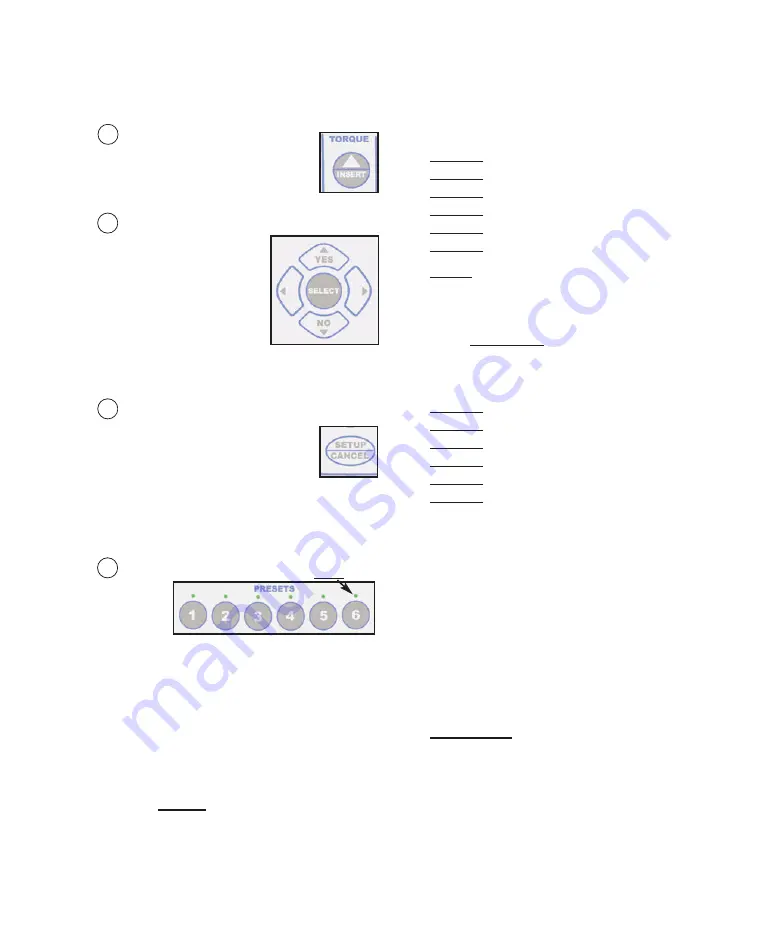

12 INSERT:

Allows user to enter a blank

space into characters when

editing the Preset button

settings on the display.

13 Display Edit & Navigation:

Allows user to navigate

through text characters

when modifying presets.

SELECT button saves

reconfigured settings.

YES/NO buttons allow

user to interact with

visual prompts on the display (refer to

advanced editing functions on pages 13

and 15 for more information).

14 SETUP / CANCEL:

SETUP

enables the System’s

setup menu. Allows the user to

select/configure setup options

via prompts from the display

(see “System Setup” Section on page 20

for complete setup instructions).

CANCEL

exits the menu item without

changing setup settings (= Escape).

15 PRESETS 1 - 6:

Allows

the user

to store

and

quickly access up to 6 different

Implant

or

Endodontic

configurations. Each preset

can be reprogrammed by the user with

different

Implant/Endo

operating

parameters and File Series (

Endo

Mode

only). When a preset button is pressed, its

“Label” (name and settings) are

automatically displayed. Green LEDs

indicate which preset is active.

a.

For

Implant

applications, Preset buttons

1 - 6 are preprogammed at the factory for

the following procedures:

Preset 1 - Site Preparation

Preset 2 - Pilot Drill

Preset 3 - Finish Drill / Reamer

Preset 4 - Tap Forward

Preset 5 - Reverse Tap

Preset 6 - Install Implant /Abutment

NOTE:

Refer to

Implant Preset Section

on page 13, and Chart 1 on page 14, for

complete Preset editing instructions and

operating parameters.

b.

For

Endodontic

applications, Preset

buttons 1 - 6 are preprogammed with the

following DENTSPLY Tulsa Dental

Specialties File Series*:

Preset 1:

Pathfile® Files

Preset 2:

ProTaper Next™ Files

Preset 3:

ProTaper® Universal Files

Preset 4:

VORTEX® 04 & 06 Taper Files

Preset 5:

GT® Series 20, 30, 40 Files

Preset 6:

GT® Series X™ (4) Files

Press desired Preset button once to select.

(

NOTE:

The message “Loading Default

Series” will appear briefly whenever any

Endo

Preset is accessed for the first time,

or after factory defaults have been restored.)

Then press the button repeatedly to cycle

through all the files in Files Series. Use

Up/Down arrow buttons to view operating

parameters for the specific File displayed.

NOTE:

Refer to

Endo Preset Section

on

page 15 for complete Preset editing

instructions. See Charts 2 and 3, pages 18

& 19, for File Presets and File Library.

IMPORTANT:

The above default Preset

settings will be restored whenever the

unit’s factory default settings are recalled

or when the unit has been reprogrammed

with new software. All user customized

presets will be lost.

*

The File Series listed above are registered

trademarks of DENTSPLY Tulsa Dental Specialties.

(Note: Green LEDs

indicate active Preset.)

Summary of Contents for AEU-7000E

Page 31: ...29 NOTES...