3

7.

Install irrigation tubing set in pump.

CAUTION: Never connect or disconnect

the bag spike to the irrigation bag over

the console. Waste spilled onto the con-

sole can damage the unit.

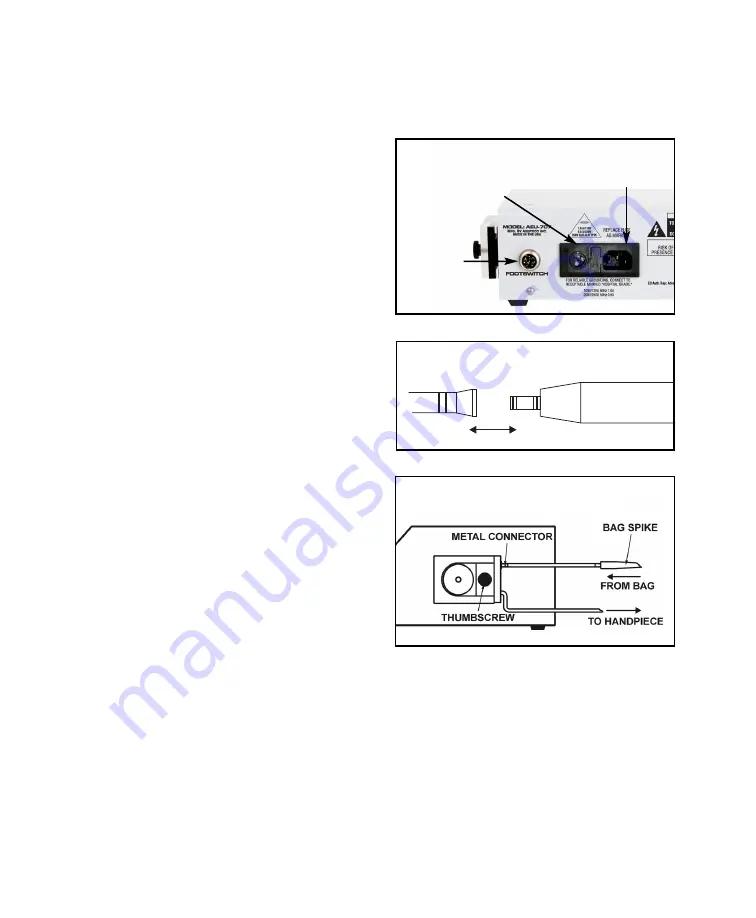

a.

Thread tubing through pump following the

diagram in Figure 4. First remove the clear

pump cover by unscrewing the thumbscrew

on top.

b.

Grasp the metal connector and tubing,

stretching the tubing slightly. Insert into the

slot on the top of the pump block, making

sure to position the metal connector on the

outside edge of the block as shown.

c.

Guide the tubing around the rollers with

slight tension and insert into bottom slot on

the pump block.

d.

While maintaining tension on the tubing,

check that tubing is centered on the rollers

and is completely tucked into slots on pump

block. Then replace clear pump cover by

sliding into position from front to back and

securing with the thumbscrew.

e.

Route the remaining length of tubing to

the handpiece and connect to the irrigation

clip. Secure the tubing to the motor cord with

clip set provided.

f.

Remove the protective cover from the irri-

gation bag and insert the bag spike into the

I.V. port. Hang the bag from the bag hanger

rod.

Fig.4 Irrigation Tubing Set

Fig.2 - Console Back

POWER

CORD IN

FOOT

SWITCH IN

VOLTAGE

SELECTOR SWITCH

Fig. 3 - Handpiece/Motor Connection