11

AMC‑15

MAINTENANCE AND STERILIZATION

1.

WASTE REMOVAL —

Empty

the waste tank daily.

Waste removal steps:

a.

Open the waste compart-

ment door on the rear of

the unit.

b.

Remove the end of waste

hose from tethered hose

clamp

A

, then direct the

waste hose to a suitable

drain.

c.

Switch ON the waste purge pump

B

to empty the waste

tank. It may take a minute before waste water begins to

flow from the end of the hose.

d.

Return the end of the waste hose into the clamp

A

, then

pinch clamp closed to prevent leakage.

The type of optional amalgam separator used with the

AMC-15 requires no settlement time before emptying the

waste tank.

2.

WASTE SYSTEM CLEANING —

After emptying the waste

tank each day, the waste system should be cleaned.

The waste system consists of:

• Waste tank

• Waste discharge hose

• HVE (high volume ejector) valve and vacuum line

• Saliva ejector (low volume) valve and vacuum line

Cleaning steps:

a.

Prepare 1 liter of a 1:10 bleach solution (1 part household

bleach to 9 parts water).

b.

Remove the disposable ends from both the HVE and saliva

ejector valves.

c.

Vacuum half of the bleach solution through the HVE valve,

then the other half through the saliva ejector valve by

putting the tip of each valve in the bleach solution.

d.

Flush each valve and line by vacuuming 1/2 liter of clean

water through each valve.

e.

Empty the waste tank following the instructions in step 1

above.

f.

Clean the outside of the ejector valves and hoses with a

disinfectant solution.

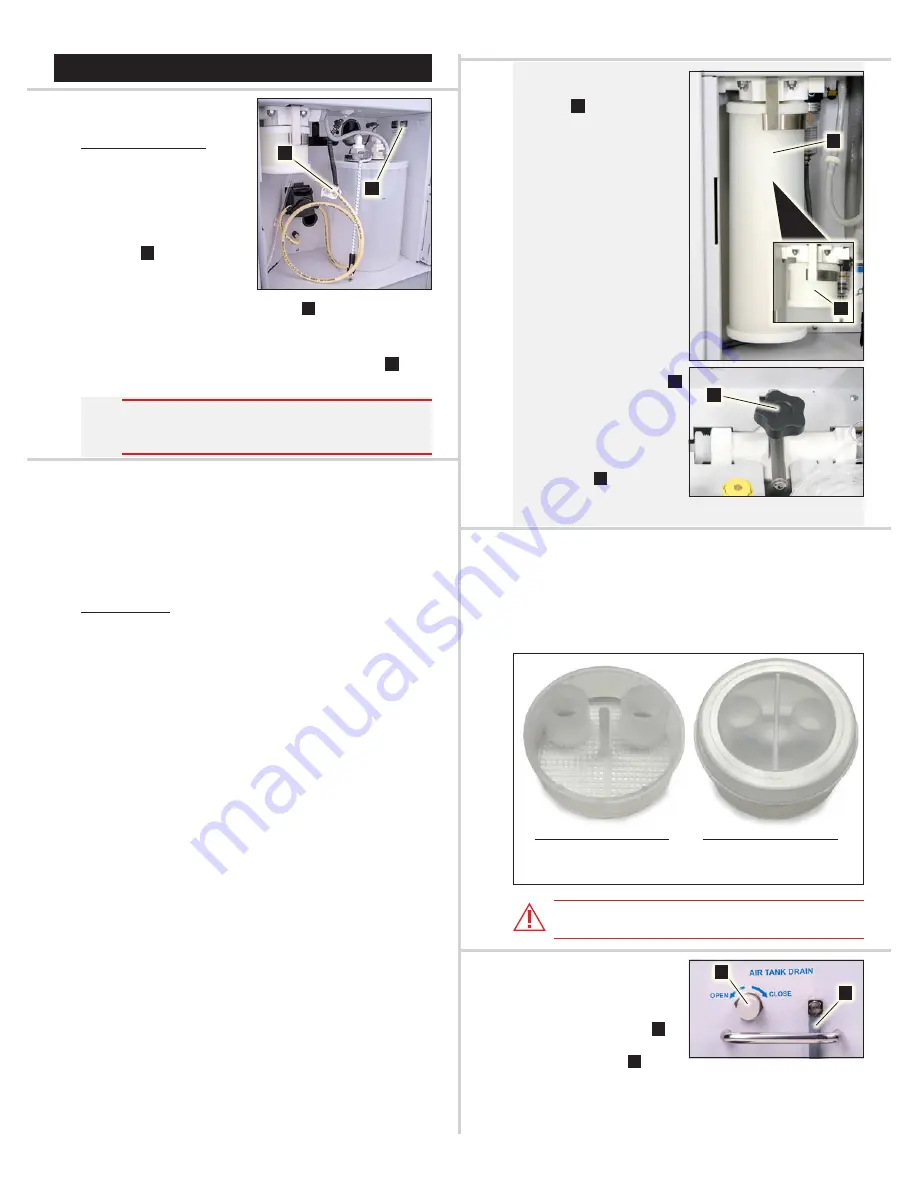

3.

AMALGAM SEPARATOR

—

The

optional

amalgam

separator

A

is located in the

waste compartment. The

separator filters out particu-

late matter while the waste

water is being pumped out of

the unit. A significant drop in

waste discharge pressure will

occur when the amalgam sep-

arator becomes full of solids.

Replacement amalgam sep-

arators (PN 730595) are avail-

able through Aseptico. Refer

to the label on the amalgam

separator for the address of

an approved amalgam recy-

cler. Replace the separator

by unscrewing the amalgam

separator retaining knob

B

located under the top lid,

and removing the amalgam

separator from the waste

compartment. NOTE: You can

operate the AMC-15 with the

bypass filter

C

installed in

place of the amalgam separa-

tor, where permitted.

4.

AMALGAM SOLIDS TRAP —

Replace the disposable

amalgam solids trap routinely. The performance of the

vacuum system will decrease significantly as the trap fills

up with solids. The trap sits inside the central vacuum canis-

ter located under the top lid. Keep spare traps in stock. The

AMC-15 uses standard 1 7/8” traps (both open and closed type

traps are compatible):

OPEN TYPE CLOSED TYPE

PART NO. QUANTITY

PART NO. QUANTITY

AA-29

1

AA-290VS

1

AA-29-100

100

AA-290VS-100

100

NOTE:

Check with state laws regarding the recycling of

amalgam solids waste.

5.

AIR TANK PURGE —

Empty

the air tank daily to remove

condensation from air tank.

Place a container underneath

the air tank drain hose

A

to

catch water. Rotate the air

tank pressure knob

B

count-

er-clockwise to empty the air tank, then rotate knob clockwise

to close valve when done.

A

B

B

A

C

B

A

Summary of Contents for AMC-15

Page 1: ...OPERATION MAINTENANCE MANUAL AMC 15 Mobile Dental Cart...

Page 17: ...17 AMC 15 NOTES...

Page 18: ...18 AMC 15...

Page 19: ...19 AMC 15...